Total Productive Maintenance (TPM) emphasizes a holistic approach involving all employees to maximize equipment efficiency and minimize downtime through planned activities. Autonomous Maintenance (AM) empowers operators to take responsibility for routine maintenance tasks such as cleaning, inspection, and lubrication to detect abnormalities early and prevent breakdowns. While TPM integrates cross-functional teams for strategic maintenance planning, AM focuses on daily, operator-driven upkeep to maintain equipment reliability.

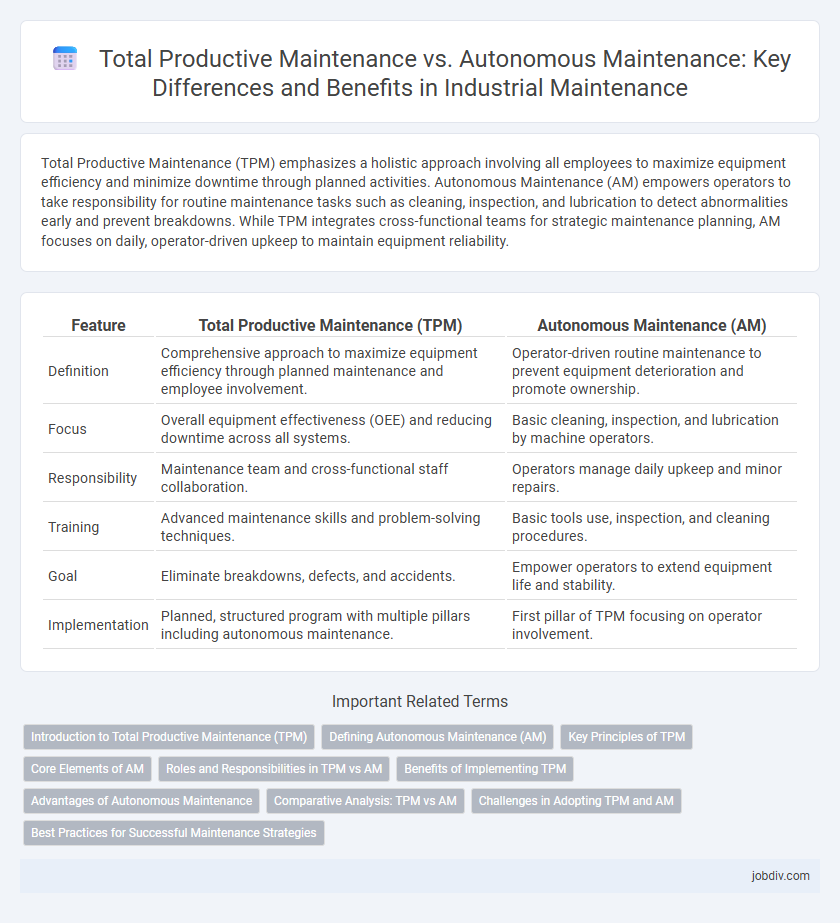

Table of Comparison

| Feature | Total Productive Maintenance (TPM) | Autonomous Maintenance (AM) |

|---|---|---|

| Definition | Comprehensive approach to maximize equipment efficiency through planned maintenance and employee involvement. | Operator-driven routine maintenance to prevent equipment deterioration and promote ownership. |

| Focus | Overall equipment effectiveness (OEE) and reducing downtime across all systems. | Basic cleaning, inspection, and lubrication by machine operators. |

| Responsibility | Maintenance team and cross-functional staff collaboration. | Operators manage daily upkeep and minor repairs. |

| Training | Advanced maintenance skills and problem-solving techniques. | Basic tools use, inspection, and cleaning procedures. |

| Goal | Eliminate breakdowns, defects, and accidents. | Empower operators to extend equipment life and stability. |

| Implementation | Planned, structured program with multiple pillars including autonomous maintenance. | First pillar of TPM focusing on operator involvement. |

Introduction to Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) is a comprehensive approach designed to maximize equipment effectiveness by involving all employees in proactive maintenance activities. Unlike Autonomous Maintenance, where operators handle routine upkeep, TPM integrates cross-functional teams to identify and eliminate losses in equipment performance, quality, and safety. This method enhances productivity through continuous improvement, equipment reliability, and reduced downtime, driving overall operational excellence.

Defining Autonomous Maintenance (AM)

Autonomous Maintenance (AM) empowers operators to take responsibility for routine maintenance tasks, such as cleaning, inspection, and lubrication, to prevent equipment breakdowns and improve reliability. It focuses on enhancing operator skills and ownership, reducing dependence on specialized maintenance staff while fostering early detection of abnormalities. AM is a key pillar within Total Productive Maintenance (TPM), emphasizing proactive involvement at the operational level for sustained equipment performance.

Key Principles of TPM

Total Productive Maintenance (TPM) centers on maximizing equipment effectiveness through proactive and preventive maintenance involving all employees. Key principles include autonomous maintenance, focused improvement, planned maintenance, quality maintenance, and early equipment management to minimize downtime and defects. Autonomous maintenance empowers operators to perform routine maintenance tasks, enhancing machine reliability and fostering ownership.

Core Elements of AM

Autonomous Maintenance (AM) empowers operators to take ownership of routine maintenance tasks, enhancing equipment reliability through regular cleaning, inspection, and lubrication. Core elements include initial cleaning to identify issues, elimination of contamination sources, standardization of checklists, and operator training to sustain machine condition. This approach reduces unplanned downtime and fosters a proactive maintenance culture, complementing Total Productive Maintenance's broader focus on cross-department collaboration and equipment efficiency.

Roles and Responsibilities in TPM vs AM

Total Productive Maintenance (TPM) assigns cross-functional teams and maintenance experts the responsibility of proactively improving equipment reliability and overall production efficiency. Autonomous Maintenance (AM) empowers operators to perform routine maintenance tasks such as cleaning, inspection, and lubrication, fostering ownership and early detection of equipment issues. TPM roles focus on strategic planning and continuous improvement, while AM emphasizes operator engagement and day-to-day maintenance activities.

Benefits of Implementing TPM

Implementing Total Productive Maintenance (TPM) enhances equipment efficiency by integrating proactive and preventive maintenance into daily operations, reducing unexpected breakdowns and downtime. TPM fosters collaborative teamwork and operator involvement, leading to increased machine reliability and improved production quality. These benefits result in higher overall equipment effectiveness (OEE), cost savings, and extended asset lifespan compared to traditional maintenance approaches.

Advantages of Autonomous Maintenance

Autonomous Maintenance empowers operators to take responsibility for routine upkeep, reducing equipment downtime and improving machine reliability. This proactive approach enhances early detection of abnormalities, leading to faster problem resolution and minimizing unexpected breakdowns. Implementing Autonomous Maintenance fosters greater operator engagement, which helps sustain optimal equipment performance and extends asset lifespan.

Comparative Analysis: TPM vs AM

Total Productive Maintenance (TPM) involves cross-functional teams working to optimize equipment effectiveness through planned maintenance activities, whereas Autonomous Maintenance (AM) empowers operators to perform routine maintenance tasks such as cleaning, inspection, and lubrication. TPM emphasizes minimizing downtime and improving overall equipment effectiveness (OEE) with a strategic, top-down approach, while AM focuses on operator-driven, day-to-day upkeep to prevent equipment deterioration. The key distinction lies in TPM's comprehensive framework for continuous improvement versus AM's role as a foundational pillar that encourages operator engagement and ownership in maintaining equipment condition.

Challenges in Adopting TPM and AM

Challenges in adopting Total Productive Maintenance (TPM) include the need for significant cultural transformation and employee training to foster proactive equipment management. Autonomous Maintenance (AM) faces obstacles such as inconsistent operator engagement and difficulties in maintaining standardized procedures across shifts. Both approaches demand sustained management commitment and clear communication to overcome resistance and ensure effective implementation.

Best Practices for Successful Maintenance Strategies

Implementing Total Productive Maintenance (TPM) alongside Autonomous Maintenance fosters collaborative efforts between operators and maintenance teams, enhancing equipment reliability and minimizing downtime. Best practices include regular training for operators to conduct basic maintenance tasks, systematic equipment inspections, and proactive identification of potential issues before failure occurs. Leveraging data-driven insights and continuous improvement cycles ensures optimal asset performance and extends machinery lifespan effectively.

Total Productive Maintenance vs Autonomous Maintenance Infographic

jobdiv.com

jobdiv.com