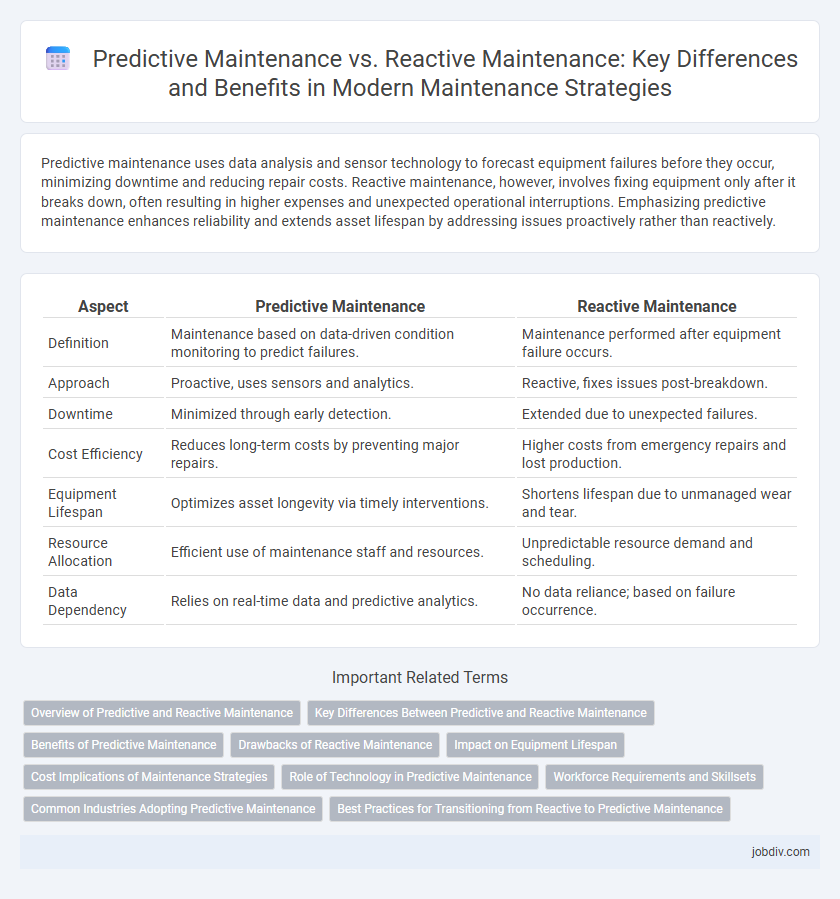

Predictive maintenance uses data analysis and sensor technology to forecast equipment failures before they occur, minimizing downtime and reducing repair costs. Reactive maintenance, however, involves fixing equipment only after it breaks down, often resulting in higher expenses and unexpected operational interruptions. Emphasizing predictive maintenance enhances reliability and extends asset lifespan by addressing issues proactively rather than reactively.

Table of Comparison

| Aspect | Predictive Maintenance | Reactive Maintenance |

|---|---|---|

| Definition | Maintenance based on data-driven condition monitoring to predict failures. | Maintenance performed after equipment failure occurs. |

| Approach | Proactive, uses sensors and analytics. | Reactive, fixes issues post-breakdown. |

| Downtime | Minimized through early detection. | Extended due to unexpected failures. |

| Cost Efficiency | Reduces long-term costs by preventing major repairs. | Higher costs from emergency repairs and lost production. |

| Equipment Lifespan | Optimizes asset longevity via timely interventions. | Shortens lifespan due to unmanaged wear and tear. |

| Resource Allocation | Efficient use of maintenance staff and resources. | Unpredictable resource demand and scheduling. |

| Data Dependency | Relies on real-time data and predictive analytics. | No data reliance; based on failure occurrence. |

Overview of Predictive and Reactive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to anticipate equipment failures before they occur, reducing downtime and maintenance costs. Reactive maintenance, by contrast, involves repairing machinery only after a breakdown, often leading to higher operational disruptions and increased expenses. Implementing predictive maintenance optimizes asset performance and extends equipment lifespan compared to the reactive approach.

Key Differences Between Predictive and Reactive Maintenance

Predictive maintenance uses sensor data and analytics to anticipate equipment failures before they occur, reducing downtime and maintenance costs. Reactive maintenance involves repairing equipment only after a breakdown happens, often leading to unplanned outages and higher repair expenses. The key difference lies in predictive maintenance's proactive approach versus reactive maintenance's reliance on post-failure intervention.

Benefits of Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to identify equipment issues before failures occur, significantly reducing downtime and repair costs. This proactive approach extends asset lifespan, optimizes resource allocation, and enhances operational efficiency by preventing unexpected breakdowns. Companies adopting predictive maintenance experience improved safety, increased productivity, and better budget management compared to reactive maintenance strategies.

Drawbacks of Reactive Maintenance

Reactive maintenance often leads to unexpected equipment failures, causing costly downtime and urgent repair expenses. This approach typically results in shorter asset lifespans due to lack of timely interventions and increased risk of safety hazards. Inefficient resource allocation and unpredictable operational disruptions are significant drawbacks of relying solely on reactive maintenance strategies.

Impact on Equipment Lifespan

Predictive maintenance uses real-time data and advanced analytics to identify potential equipment failures before they occur, significantly extending the lifespan of machinery by minimizing unplanned downtime and preventing severe damage. Reactive maintenance, which addresses repairs only after equipment failure, often leads to increased wear and tear, resulting in shorter equipment lifespans and higher replacement costs. Implementing predictive maintenance strategies enhances asset reliability and reduces lifecycle costs by proactively managing equipment health.

Cost Implications of Maintenance Strategies

Predictive maintenance reduces overall costs by preventing unexpected equipment failures and minimizing downtime through data-driven monitoring, resulting in lower repair expenses and extended asset life. Reactive maintenance often leads to higher expenses due to emergency repairs, unplanned outages, and accelerated wear of machinery components. Investing in predictive maintenance technologies enhances cost efficiency by optimizing resource allocation and reducing the frequency of costly breakdowns.

Role of Technology in Predictive Maintenance

Predictive maintenance leverages advanced technologies such as IoT sensors, machine learning algorithms, and real-time data analytics to monitor equipment conditions and predict failures before they occur. This technology-driven approach enables precise scheduling of maintenance activities, reducing unplanned downtime and optimizing resource allocation. In contrast, reactive maintenance lacks these technological tools, relying solely on addressing equipment issues after failures, which often leads to higher costs and operational disruptions.

Workforce Requirements and Skillsets

Predictive maintenance demands a highly skilled workforce proficient in data analysis, IoT technologies, and condition monitoring tools to anticipate equipment failures before they occur. Reactive maintenance relies primarily on technicians with strong troubleshooting and repair skills, responding to issues as they arise without prior warning. Investing in continuous training for predictive maintenance teams enhances operational efficiency, while reactive maintenance requires readiness for rapid problem-solving under time constraints.

Common Industries Adopting Predictive Maintenance

Predictive maintenance is widely adopted in industries such as manufacturing, oil and gas, automotive, and aerospace due to its ability to reduce equipment downtime and maintenance costs. By leveraging IoT sensors and machine learning algorithms, these sectors can accurately predict failures before they occur, enhancing operational efficiency. Reactive maintenance, while simpler, often leads to higher unplanned downtime and increased repair expenses in comparison.

Best Practices for Transitioning from Reactive to Predictive Maintenance

Transitioning from reactive to predictive maintenance involves integrating IoT sensors and advanced analytics to monitor equipment health in real-time, enabling early fault detection and reducing downtime. Implementing a centralized maintenance management system and training personnel on data interpretation enhances decision-making accuracy and operational efficiency. Regularly reviewing performance metrics and adjusting predictive models ensures continuous improvement and maximizes return on investment.

Predictive Maintenance vs Reactive Maintenance Infographic

jobdiv.com

jobdiv.com