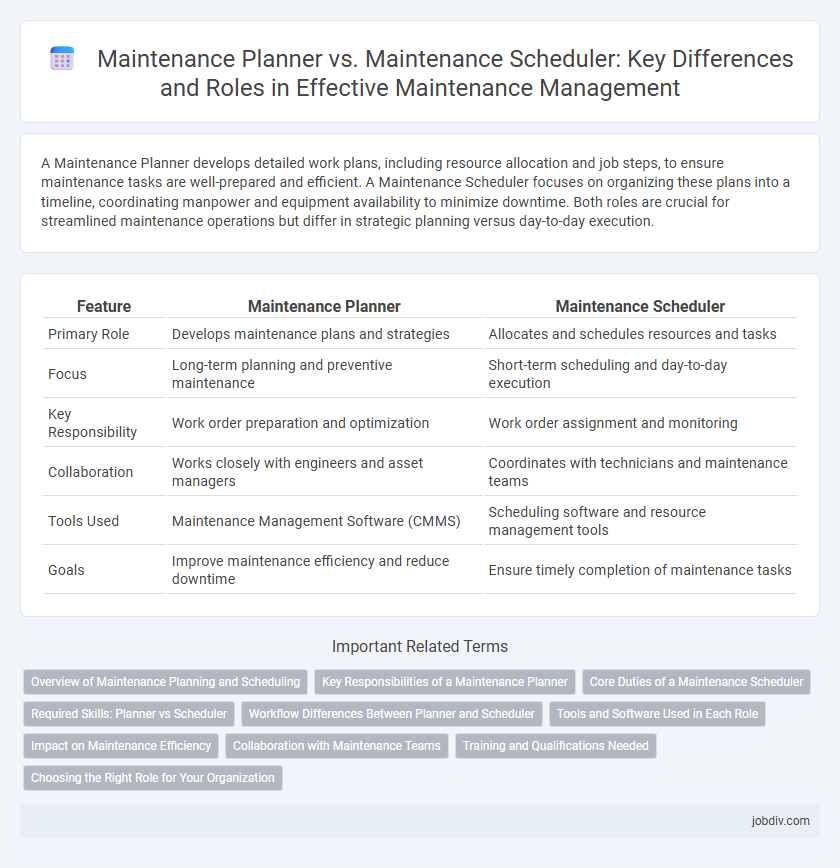

A Maintenance Planner develops detailed work plans, including resource allocation and job steps, to ensure maintenance tasks are well-prepared and efficient. A Maintenance Scheduler focuses on organizing these plans into a timeline, coordinating manpower and equipment availability to minimize downtime. Both roles are crucial for streamlined maintenance operations but differ in strategic planning versus day-to-day execution.

Table of Comparison

| Feature | Maintenance Planner | Maintenance Scheduler |

|---|---|---|

| Primary Role | Develops maintenance plans and strategies | Allocates and schedules resources and tasks |

| Focus | Long-term planning and preventive maintenance | Short-term scheduling and day-to-day execution |

| Key Responsibility | Work order preparation and optimization | Work order assignment and monitoring |

| Collaboration | Works closely with engineers and asset managers | Coordinates with technicians and maintenance teams |

| Tools Used | Maintenance Management Software (CMMS) | Scheduling software and resource management tools |

| Goals | Improve maintenance efficiency and reduce downtime | Ensure timely completion of maintenance tasks |

Overview of Maintenance Planning and Scheduling

Maintenance planning involves developing a comprehensive strategy to ensure the availability of resources, materials, and labor required for upcoming maintenance tasks. Maintenance scheduling focuses on assigning specific dates and times to these planned activities to optimize workflow, minimize downtime, and coordinate with operational demands. Together, maintenance planning and scheduling enhance asset reliability and improve maintenance team efficiency by aligning resources with maintenance priorities.

Key Responsibilities of a Maintenance Planner

A Maintenance Planner is responsible for developing detailed maintenance work plans, coordinating with engineering and operations teams to ensure resource availability, and creating preventive maintenance schedules to minimize equipment downtime. Key tasks include analyzing equipment history data to optimize maintenance intervals, generating work orders with precise instructions, and managing spare parts inventory to support planned maintenance activities. This role ensures efficient allocation of labor and materials, improving overall asset reliability and operational efficiency.

Core Duties of a Maintenance Scheduler

The core duties of a Maintenance Scheduler include developing detailed work schedules to ensure timely completion of maintenance tasks, coordinating resources such as labor, materials, and equipment, and monitoring job progress to adjust plans proactively. They prioritize maintenance activities based on asset criticality and operational demands, aiming to maximize uptime and reduce downtime. Effective communication with maintenance teams and stakeholders facilitates smooth execution and adherence to maintenance plans.

Required Skills: Planner vs Scheduler

Maintenance Planners require strong analytical skills, expertise in resource allocation, and proficiency in predictive maintenance techniques to forecast and coordinate long-term maintenance activities. Maintenance Schedulers need exceptional time management abilities, attention to detail, and proficiency in scheduling software to efficiently assign tasks and optimize daily work orders. Both roles demand effective communication and collaboration with maintenance teams to ensure timely equipment availability and minimize downtime.

Workflow Differences Between Planner and Scheduler

Maintenance planners focus on developing detailed work orders and defining resources, materials, and timelines to ensure efficient task execution. Maintenance schedulers prioritize sequencing and assigning these tasks to teams, optimizing workloads and minimizing downtime through calendar management. The planner's workflow emphasizes preparation and documentation, while the scheduler's workflow centers on real-time coordination and adjusting schedules based on operational constraints.

Tools and Software Used in Each Role

Maintenance Planners primarily utilize Computerized Maintenance Management Systems (CMMS) like IBM Maximo and SAP PM to develop detailed maintenance plans and optimize resource allocation. Maintenance Schedulers often rely on tools such as Microsoft Project or specialized scheduling modules within CMMS platforms to coordinate and sequence maintenance tasks efficiently. Both roles benefit from software integration with asset management systems and mobile applications that enhance real-time communication and updates.

Impact on Maintenance Efficiency

A Maintenance Planner enhances maintenance efficiency by developing detailed work plans, estimating resources, and ensuring parts availability, which reduces downtime and prevents work delays. The Maintenance Scheduler optimizes workforce deployment and sequence of tasks, maximizing equipment utilization and minimizing idle time. Together, their roles synergize to streamline maintenance operations, significantly improving overall productivity and reducing operational costs.

Collaboration with Maintenance Teams

Maintenance planners develop detailed maintenance plans and allocate resources, ensuring all necessary parts and tools are available for upcoming tasks. Maintenance schedulers coordinate with technicians and other team members to assign work orders, monitor progress, and adjust schedules based on real-time information. Effective collaboration between planners and schedulers enhances resource utilization, reduces downtime, and streamlines maintenance workflows.

Training and Qualifications Needed

Maintenance Planners require advanced knowledge in asset management and reliability engineering, often holding certifications such as Certified Maintenance & Reliability Professional (CMRP) to effectively develop maintenance strategies and work scopes. Maintenance Schedulers need strong organizational and time management skills, typically supported by training in scheduling software and understanding operational workflows to coordinate maintenance activities efficiently. Both roles demand industry-specific technical training, with planners focusing more on strategic planning and schedulers on tactical execution to ensure seamless maintenance operations.

Choosing the Right Role for Your Organization

Maintenance planners develop detailed work orders and allocate resources for preventive and corrective maintenance, ensuring optimal asset reliability and cost efficiency. Maintenance schedulers coordinate and sequence maintenance tasks, aligning workforce availability and equipment downtime to maximize operational continuity. Selecting the right role depends on your organization's size and complexity, with planners suited for strategic planning in larger operations and schedulers ideal for managing daily task execution in smaller teams.

Maintenance Planner vs Maintenance Scheduler Infographic

jobdiv.com

jobdiv.com