Facility maintenance ensures the overall building infrastructure remains safe, clean, and functional by addressing structural repairs, HVAC systems, plumbing, and electrical components. Equipment maintenance targets the upkeep and repair of specific machinery and tools to prevent breakdowns and extend operational life through regular inspections and servicing. Prioritizing both types of maintenance reduces downtime, enhances safety, and improves efficiency within industrial and commercial environments.

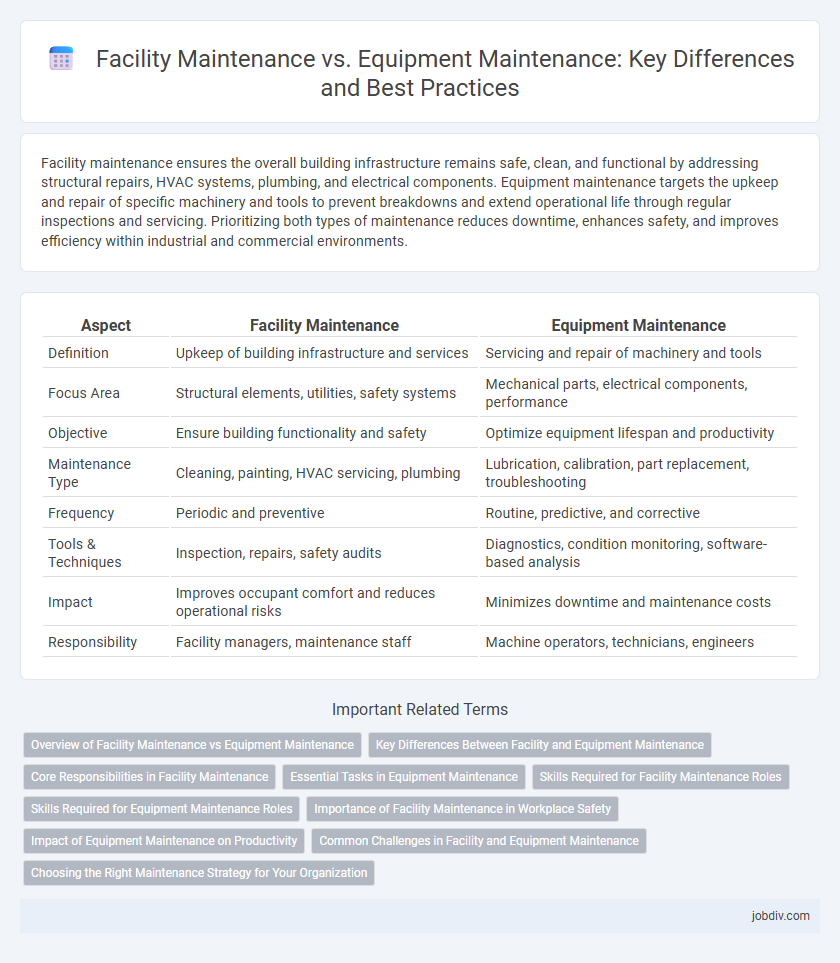

Table of Comparison

| Aspect | Facility Maintenance | Equipment Maintenance |

|---|---|---|

| Definition | Upkeep of building infrastructure and services | Servicing and repair of machinery and tools |

| Focus Area | Structural elements, utilities, safety systems | Mechanical parts, electrical components, performance |

| Objective | Ensure building functionality and safety | Optimize equipment lifespan and productivity |

| Maintenance Type | Cleaning, painting, HVAC servicing, plumbing | Lubrication, calibration, part replacement, troubleshooting |

| Frequency | Periodic and preventive | Routine, predictive, and corrective |

| Tools & Techniques | Inspection, repairs, safety audits | Diagnostics, condition monitoring, software-based analysis |

| Impact | Improves occupant comfort and reduces operational risks | Minimizes downtime and maintenance costs |

| Responsibility | Facility managers, maintenance staff | Machine operators, technicians, engineers |

Overview of Facility Maintenance vs Equipment Maintenance

Facility maintenance encompasses the comprehensive upkeep of building infrastructure, including HVAC systems, electrical wiring, plumbing, and structural components to ensure safety, functionality, and compliance with regulations. Equipment maintenance focuses specifically on the servicing, repair, and calibration of machinery and tools used in operational processes to maximize performance and minimize downtime. Both types of maintenance are critical for organizational efficiency, with facility maintenance ensuring a safe environment and equipment maintenance optimizing production capabilities.

Key Differences Between Facility and Equipment Maintenance

Facility maintenance involves the upkeep of the physical building infrastructure, including HVAC systems, plumbing, electrical wiring, and structural components, ensuring the entire environment is safe and operational. Equipment maintenance focuses specifically on machinery and tools, emphasizing routine inspections, repairs, and calibrations to maintain optimal performance and prevent downtime. The key difference lies in the scope: facility maintenance covers the entire premises, while equipment maintenance targets individual machines within the facility.

Core Responsibilities in Facility Maintenance

Facility maintenance focuses on managing the overall building infrastructure, including HVAC systems, electrical wiring, plumbing, and structural integrity to ensure a safe and functional environment. Core responsibilities also involve routine inspections, preventive maintenance schedules, and coordination with vendors for repairs and upgrades. This contrasts with equipment maintenance, which targets the upkeep and repair of specific machinery or tools within the facility.

Essential Tasks in Equipment Maintenance

Essential tasks in equipment maintenance include regular inspections, lubrication, calibration, and timely replacement of worn components to ensure optimal performance and prevent unexpected breakdowns. Predictive maintenance techniques, such as vibration analysis and thermal imaging, help detect potential issues early, reducing downtime and extending equipment lifespan. Proper equipment maintenance enhances safety, improves efficiency, and lowers overall operational costs.

Skills Required for Facility Maintenance Roles

Facility maintenance roles demand skills in HVAC systems, electrical knowledge, plumbing, and building repair, essential for preserving infrastructure integrity and safety. Proficiency in preventive maintenance techniques, troubleshooting, and compliance with health and safety regulations directly impacts operational efficiency. Effective communication and project management abilities are also critical for coordinating maintenance tasks and minimizing facility downtime.

Skills Required for Equipment Maintenance Roles

Equipment maintenance roles demand specialized technical skills, including proficiency in diagnosing mechanical and electrical faults, understanding complex machinery systems, and using diagnostic tools and software. Technicians must have strong problem-solving abilities, hands-on expertise in repair and calibration, and knowledge of safety standards and compliance regulations. Continuous training in emerging technologies and equipment-specific protocols is essential to ensure optimal performance and minimize downtime.

Importance of Facility Maintenance in Workplace Safety

Facility maintenance is crucial for workplace safety as it ensures that the physical environment, including building structures, lighting, and HVAC systems, remains in optimal condition to prevent hazards. Proper upkeep helps reduce accidents caused by faulty infrastructure or poor environmental conditions, thus protecting employees and visitors. Regular facility inspections and timely repairs contribute significantly to compliance with safety regulations and minimize operational disruptions.

Impact of Equipment Maintenance on Productivity

Equipment maintenance directly enhances operational efficiency by minimizing unplanned downtime and extending machinery lifespan. Regular inspections and timely repairs prevent breakdowns, ensuring consistent production flow and reducing costly delays. Optimized equipment performance contributes significantly to overall facility productivity, lowering maintenance costs and boosting output quality.

Common Challenges in Facility and Equipment Maintenance

Common challenges in facility and equipment maintenance include unexpected breakdowns, inadequate preventive maintenance schedules, and limited access to skilled technicians. Both facilities and equipment face issues related to aging infrastructure, budget constraints, and difficulties in tracking maintenance history effectively. Implementing integrated maintenance management systems can help address these challenges by improving resource allocation and predictive maintenance capabilities.

Choosing the Right Maintenance Strategy for Your Organization

Facility maintenance ensures the physical infrastructure remains safe, functional, and compliant with regulations, covering HVAC, plumbing, and structural repairs. Equipment maintenance targets machinery and tools to optimize performance, minimize downtime, and extend asset lifespan through preventive, predictive, or corrective methods. Selecting the right maintenance strategy depends on factors such as organizational goals, asset criticality, operational costs, and resource availability to balance efficiency and risk management effectively.

Facility Maintenance vs Equipment Maintenance Infographic

jobdiv.com

jobdiv.com