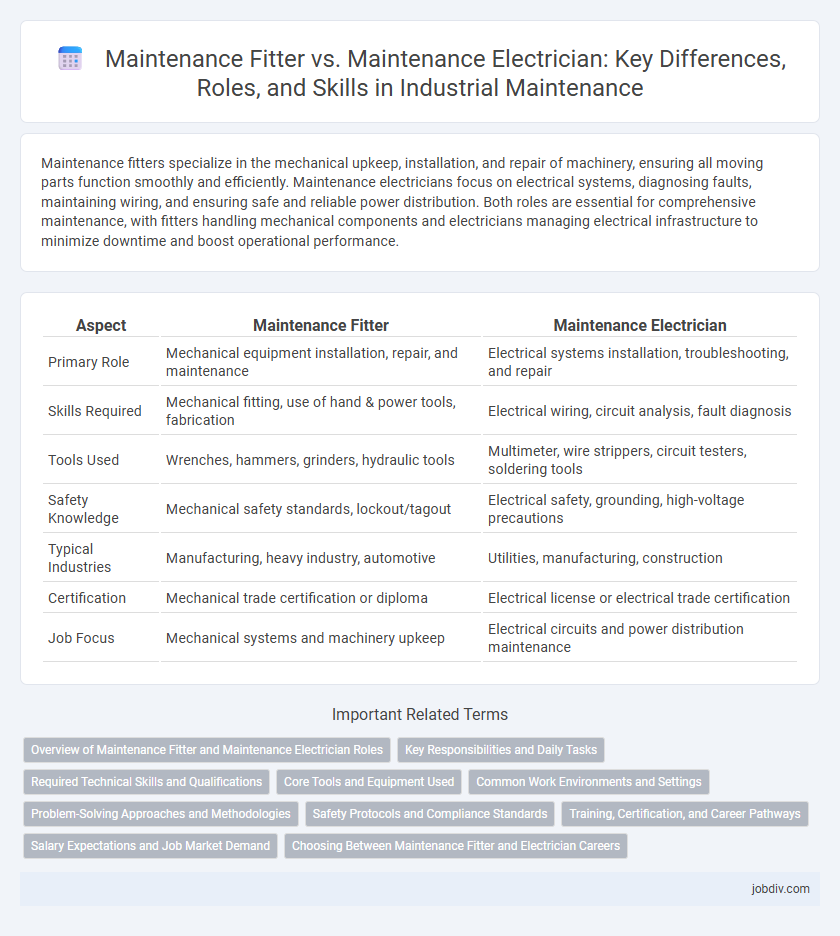

Maintenance fitters specialize in the mechanical upkeep, installation, and repair of machinery, ensuring all moving parts function smoothly and efficiently. Maintenance electricians focus on electrical systems, diagnosing faults, maintaining wiring, and ensuring safe and reliable power distribution. Both roles are essential for comprehensive maintenance, with fitters handling mechanical components and electricians managing electrical infrastructure to minimize downtime and boost operational performance.

Table of Comparison

| Aspect | Maintenance Fitter | Maintenance Electrician |

|---|---|---|

| Primary Role | Mechanical equipment installation, repair, and maintenance | Electrical systems installation, troubleshooting, and repair |

| Skills Required | Mechanical fitting, use of hand & power tools, fabrication | Electrical wiring, circuit analysis, fault diagnosis |

| Tools Used | Wrenches, hammers, grinders, hydraulic tools | Multimeter, wire strippers, circuit testers, soldering tools |

| Safety Knowledge | Mechanical safety standards, lockout/tagout | Electrical safety, grounding, high-voltage precautions |

| Typical Industries | Manufacturing, heavy industry, automotive | Utilities, manufacturing, construction |

| Certification | Mechanical trade certification or diploma | Electrical license or electrical trade certification |

| Job Focus | Mechanical systems and machinery upkeep | Electrical circuits and power distribution maintenance |

Overview of Maintenance Fitter and Maintenance Electrician Roles

Maintenance Fitters specialize in assembling, repairing, and maintaining mechanical equipment, ensuring optimal functionality of machinery such as conveyor systems, pumps, and engines. Maintenance Electricians focus on electrical systems, handling tasks like wiring, troubleshooting electrical faults, and installing control panels to maintain safe and efficient power distribution. Both roles require technical expertise but differ primarily in their emphasis on mechanical versus electrical components within industrial and manufacturing environments.

Key Responsibilities and Daily Tasks

Maintenance Fitters primarily focus on mechanical systems, involving tasks such as assembling, installing, and repairing machinery and equipment, ensuring optimal mechanical performance. Maintenance Electricians handle electrical components by wiring, troubleshooting, and maintaining electrical systems to prevent downtime and ensure safety compliance. Both roles require regular inspections, preventive maintenance, and collaboration to minimize operational disruptions and extend equipment lifespan.

Required Technical Skills and Qualifications

Maintenance Fitters require proficiency in mechanical systems, welding, hydraulics, pneumatics, and blueprint reading, often holding certifications such as a mechanical engineering diploma or an industrial maintenance technician certificate. Maintenance Electricians demand expertise in electrical wiring, circuit troubleshooting, PLC programming, and adherence to electrical codes, commonly possessing qualifications like an electrician's license or a diploma in electrical engineering technology. Both roles emphasize hands-on technical skills, safety compliance, and continuous training to address equipment faults and ensure operational efficiency.

Core Tools and Equipment Used

Maintenance fitters primarily use core tools such as wrenches, spanners, hammers, and pneumatic tools for assembly, disassembly, and repair of mechanical components. Maintenance electricians rely on multimeters, wire strippers, insulation testers, and soldering irons to diagnose and fix electrical circuits, wiring, and control systems. Both roles require specialized equipment like safety gloves, locking devices, and portable power tools to ensure efficient and safe maintenance operations.

Common Work Environments and Settings

Maintenance fitters and maintenance electricians typically work in industrial plants, manufacturing facilities, and commercial buildings. Both professionals operate in environments requiring strict adherence to safety protocols, often dealing with heavy machinery and complex mechanical or electrical systems. While fitters focus on mechanical repairs and equipment assembly, electricians handle electrical wiring, control systems, and troubleshooting electrical faults within the same work settings.

Problem-Solving Approaches and Methodologies

Maintenance Fitters excel in mechanical troubleshooting by systematically diagnosing equipment failures through physical inspections and the application of precision tools, emphasizing hands-on repairs and preventive techniques. Maintenance Electricians specialize in electrical problem-solving using circuit analysis, wiring diagnostics, and adherence to safety codes to identify and rectify electrical faults efficiently. Both roles integrate root cause analysis and use diagnostic software but differ in their focus areas, with fitters addressing mechanical components and electricians concentrating on electrical systems.

Safety Protocols and Compliance Standards

Maintenance Fitters and Maintenance Electricians must strictly adhere to safety protocols such as lockout/tagout procedures and personal protective equipment (PPE) requirements to prevent workplace injuries. Compliance standards are governed by OSHA regulations, including NFPA 70E for electrical safety and ISO 45001 for occupational health and safety management systems. Both roles require regular safety training and certification updates to ensure adherence to evolving industry safety codes and legal mandates.

Training, Certification, and Career Pathways

Maintenance fitters undergo extensive mechanical training focusing on machinery installation, repair, and preventative maintenance, often requiring certifications such as the NVQ Level 3 in Mechanical Maintenance. Maintenance electricians receive specialized electrical training including wiring, troubleshooting, and compliance with electrical safety standards, typically necessitating certifications like the City & Guilds Electrical Installation or an equivalent license. Career pathways for maintenance fitters often lead to roles in plant maintenance supervision or mechanical engineering, while maintenance electricians may advance toward electrical engineering, system design, or electrical maintenance management positions.

Salary Expectations and Job Market Demand

Maintenance Fitters typically earn between $45,000 and $65,000 annually, while Maintenance Electricians often command higher salaries ranging from $55,000 to $75,000 due to specialized electrical skills. The job market demand for Maintenance Electricians is growing faster, driven by increasing automation and electrical system complexity in industries. Both roles remain essential, but electricians generally have broader opportunities and higher earning potential in manufacturing, construction, and utilities sectors.

Choosing Between Maintenance Fitter and Electrician Careers

Choosing between a Maintenance Fitter and a Maintenance Electrician career depends on the specific technical skills and industry demands. Maintenance Fitters specialize in mechanical repairs, assembly, and equipment alignment, while Maintenance Electricians focus on electrical systems installation, troubleshooting, and compliance with safety codes. Career growth and salary potential vary based on certifications, experience, and the sector, with both roles essential for industrial maintenance and operational efficiency.

Maintenance Fitter vs Maintenance Electrician Infographic

jobdiv.com

jobdiv.com