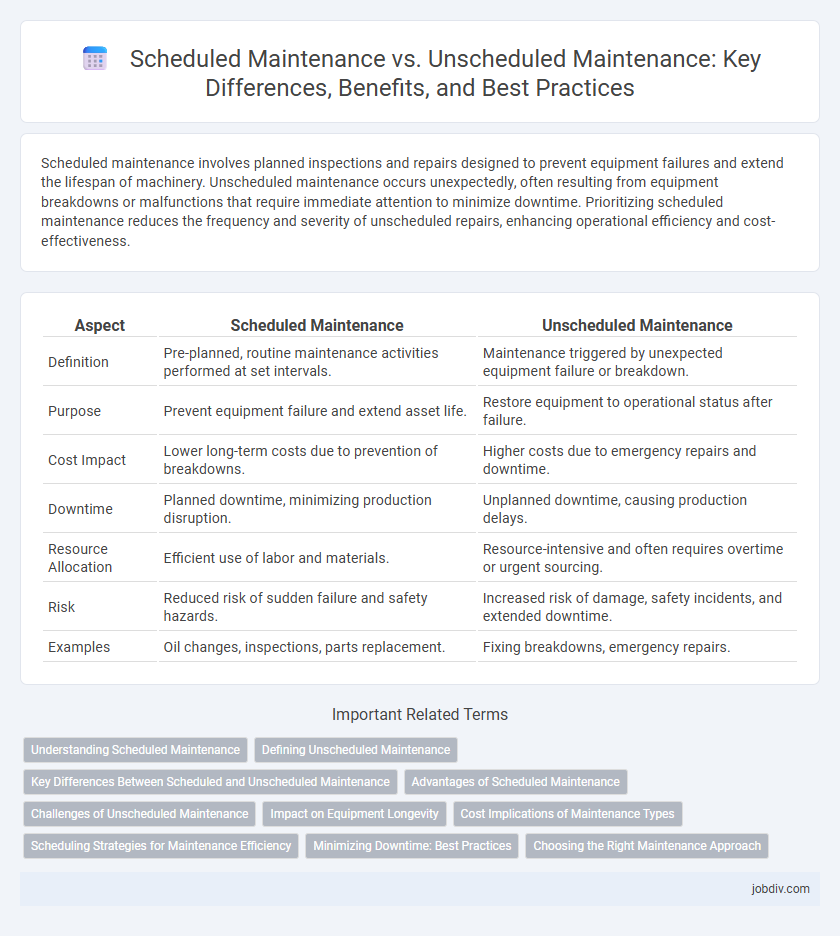

Scheduled maintenance involves planned inspections and repairs designed to prevent equipment failures and extend the lifespan of machinery. Unscheduled maintenance occurs unexpectedly, often resulting from equipment breakdowns or malfunctions that require immediate attention to minimize downtime. Prioritizing scheduled maintenance reduces the frequency and severity of unscheduled repairs, enhancing operational efficiency and cost-effectiveness.

Table of Comparison

| Aspect | Scheduled Maintenance | Unscheduled Maintenance |

|---|---|---|

| Definition | Pre-planned, routine maintenance activities performed at set intervals. | Maintenance triggered by unexpected equipment failure or breakdown. |

| Purpose | Prevent equipment failure and extend asset life. | Restore equipment to operational status after failure. |

| Cost Impact | Lower long-term costs due to prevention of breakdowns. | Higher costs due to emergency repairs and downtime. |

| Downtime | Planned downtime, minimizing production disruption. | Unplanned downtime, causing production delays. |

| Resource Allocation | Efficient use of labor and materials. | Resource-intensive and often requires overtime or urgent sourcing. |

| Risk | Reduced risk of sudden failure and safety hazards. | Increased risk of damage, safety incidents, and extended downtime. |

| Examples | Oil changes, inspections, parts replacement. | Fixing breakdowns, emergency repairs. |

Understanding Scheduled Maintenance

Scheduled maintenance involves performing regular, planned inspections and servicing of equipment to prevent unexpected failures and extend asset lifespan. This proactive approach relies on detailed maintenance schedules based on manufacturer recommendations, equipment usage, and historical performance data. By prioritizing scheduled maintenance, organizations can optimize operational efficiency, reduce downtime, and minimize repair costs.

Defining Unscheduled Maintenance

Unscheduled maintenance refers to unexpected repairs or corrective actions performed when equipment fails or malfunctions without prior notice, causing interruptions in operations. It often results in higher costs and increased downtime compared to scheduled maintenance, which is planned and routine. Effective asset management strategies aim to minimize unscheduled maintenance by implementing predictive and preventive measures.

Key Differences Between Scheduled and Unscheduled Maintenance

Scheduled maintenance involves planned activities based on time or usage intervals to prevent equipment failure and optimize performance, while unscheduled maintenance occurs reactively due to unexpected breakdowns. Scheduled maintenance minimizes downtime and extends asset lifespan through routine inspections and replacements, whereas unscheduled maintenance often leads to costly repairs and operational disruptions. Key differences include predictability, cost implications, and impact on productivity, with scheduled maintenance emphasizing prevention and unscheduled prioritizing urgent repair.

Advantages of Scheduled Maintenance

Scheduled maintenance reduces equipment downtime by allowing regular inspections and timely repairs, which prevent unexpected failures that disrupt operations. It extends the lifespan of machinery by ensuring consistent upkeep and replacing worn components before they cause damage. This approach optimizes resource allocation, minimizing emergency repair costs and improving overall operational efficiency.

Challenges of Unscheduled Maintenance

Unscheduled maintenance poses significant challenges including unexpected downtime that disrupts production schedules, increased repair costs due to emergency service rates, and difficulty in resource allocation as maintenance teams must quickly respond without prior planning. Equipment failures during unscheduled maintenance often result in extended outages, negatively impacting overall operational efficiency and asset lifespan. The unpredictability of these events complicates inventory management for spare parts, causing delays and further escalating maintenance expenses.

Impact on Equipment Longevity

Scheduled maintenance extends equipment longevity by ensuring timely inspections, lubrication, and part replacements, preventing excessive wear and unexpected failures. Unscheduled maintenance often results from sudden breakdowns, causing increased stress on machinery and accelerated component degradation. Consistent adherence to scheduled maintenance protocols significantly reduces operational downtime and extends the overall lifespan of equipment.

Cost Implications of Maintenance Types

Scheduled maintenance reduces overall costs by preventing major breakdowns and optimizing equipment lifespan, leading to predictable budgeting and fewer emergency repairs. Unscheduled maintenance often incurs higher expenses due to unexpected downtime, costly emergency services, and potential damage escalation. Investing in regular scheduled maintenance mitigates financial risks and improves asset reliability, lowering the total cost of ownership.

Scheduling Strategies for Maintenance Efficiency

Scheduled maintenance involves planned, routine inspections and servicing based on time or usage intervals to prevent equipment failures. Unscheduled maintenance occurs unexpectedly, often causing downtime and higher costs due to urgent repairs. Implementing predictive analytics and condition-based monitoring enhances scheduling strategies by optimizing maintenance timing, reducing unplanned outages, and improving overall operational efficiency.

Minimizing Downtime: Best Practices

Scheduled maintenance involves planned inspections and repairs conducted at regular intervals to prevent equipment failures, while unscheduled maintenance addresses unexpected breakdowns that disrupt operations. Minimizing downtime requires implementing predictive analytics and real-time monitoring systems to anticipate issues before they escalate, ensuring timely interventions. Establishing clear protocols for rapid response and resource allocation during unscheduled events further reduces operational interruptions and enhances overall equipment effectiveness.

Choosing the Right Maintenance Approach

Choosing the right maintenance approach involves evaluating the operational impact and cost-effectiveness of scheduled maintenance versus unscheduled maintenance. Scheduled maintenance minimizes downtime and extends equipment lifespan by conducting proactive inspections and repairs at predetermined intervals, while unscheduled maintenance addresses unexpected failures that may cause costly production interruptions. Analyzing equipment criticality, usage patterns, and failure history helps organizations decide between preventive strategies and reactive responses to optimize asset reliability and reduce maintenance expenses.

Scheduled Maintenance vs Unscheduled Maintenance Infographic

jobdiv.com

jobdiv.com