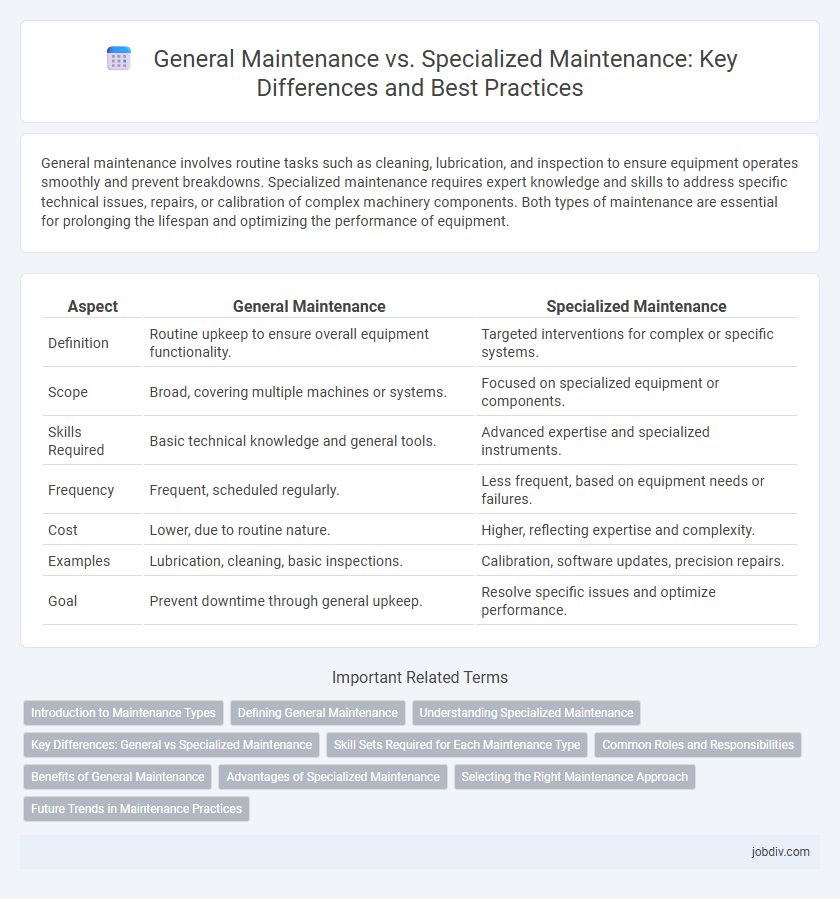

General maintenance involves routine tasks such as cleaning, lubrication, and inspection to ensure equipment operates smoothly and prevent breakdowns. Specialized maintenance requires expert knowledge and skills to address specific technical issues, repairs, or calibration of complex machinery components. Both types of maintenance are essential for prolonging the lifespan and optimizing the performance of equipment.

Table of Comparison

| Aspect | General Maintenance | Specialized Maintenance |

|---|---|---|

| Definition | Routine upkeep to ensure overall equipment functionality. | Targeted interventions for complex or specific systems. |

| Scope | Broad, covering multiple machines or systems. | Focused on specialized equipment or components. |

| Skills Required | Basic technical knowledge and general tools. | Advanced expertise and specialized instruments. |

| Frequency | Frequent, scheduled regularly. | Less frequent, based on equipment needs or failures. |

| Cost | Lower, due to routine nature. | Higher, reflecting expertise and complexity. |

| Examples | Lubrication, cleaning, basic inspections. | Calibration, software updates, precision repairs. |

| Goal | Prevent downtime through general upkeep. | Resolve specific issues and optimize performance. |

Introduction to Maintenance Types

General maintenance involves routine tasks such as cleaning, lubrication, and inspections to ensure equipment operates efficiently, while specialized maintenance requires expert skills and tools to address complex repairs and system-specific problems. General maintenance enhances overall equipment reliability, reducing unexpected breakdowns, whereas specialized maintenance extends the lifespan of critical machinery by focusing on technical and diagnostic expertise. Understanding the distinctions between these maintenance types allows organizations to allocate resources effectively and optimize operational performance.

Defining General Maintenance

General maintenance involves routine tasks such as cleaning, lubrication, and inspection that ensure the basic functionality and longevity of equipment across various industries. It includes preventive measures like tightening bolts, checking fluid levels, and replacing worn parts to avoid unexpected breakdowns. This type of maintenance is essential for keeping assets operational without requiring specialized technical skills or tools.

Understanding Specialized Maintenance

Specialized maintenance requires advanced technical skills and in-depth knowledge of specific equipment or systems, often involving diagnostics and precision repairs. Unlike general maintenance, which covers routine inspections and basic fixes, specialized maintenance addresses complex issues requiring expertise in areas such as HVAC systems, electrical components, or computerized machinery. Mastery in specialized maintenance ensures prolonged equipment lifespan, minimizes downtime, and enhances operational efficiency.

Key Differences: General vs Specialized Maintenance

General maintenance involves routine tasks such as cleaning, lubrication, and inspection designed to keep equipment operating efficiently and prevent breakdowns. Specialized maintenance requires advanced technical skills, utilizing diagnostic tools and specific expertise to address complex repairs or system calibrations. The key differences lie in the scope, complexity, and required skill level, with general maintenance focusing on broad, preventive care and specialized maintenance targeting targeted, expert interventions.

Skill Sets Required for Each Maintenance Type

General maintenance requires a broad skill set including basic electrical, plumbing, and mechanical knowledge to troubleshoot and repair common equipment issues. Specialized maintenance demands advanced expertise in specific systems such as HVAC, robotics, or IT infrastructure, often requiring certifications and in-depth technical training. The effective allocation of skills ensures optimal asset performance and minimizes downtime in maintenance operations.

Common Roles and Responsibilities

General maintenance technicians handle routine inspections, equipment cleaning, and minor repairs, ensuring operational continuity and safety compliance. Specialized maintenance professionals focus on advanced troubleshooting, system calibrations, and technical upgrades requiring specific expertise in fields like HVAC, electrical, or mechanical systems. Both roles demand adherence to safety standards, accurate documentation, and prompt reporting of maintenance activities to optimize equipment lifespan and minimize downtime.

Benefits of General Maintenance

General maintenance enhances equipment reliability by addressing routine inspections and minor repairs, reducing unplanned downtime and extending asset lifespan. This proactive approach lowers overall maintenance costs by preventing complex failures and minimizing the need for specialized intervention. Consistent general maintenance improves operational efficiency and safety across various industries by ensuring all systems function smoothly.

Advantages of Specialized Maintenance

Specialized maintenance offers targeted expertise that enhances equipment reliability and extends asset lifespan through precise diagnostics and repairs. It reduces downtime and maintenance costs by addressing specific system complexities with advanced tools and trained professionals. This focused approach improves operational efficiency and safety in industries requiring high-performance machinery.

Selecting the Right Maintenance Approach

Selecting the right maintenance approach hinges on the complexity and criticality of the equipment, with general maintenance suited for routine inspections, cleaning, and basic repairs, while specialized maintenance addresses advanced diagnostics, technical repairs, and system-specific calibrations. Evaluating equipment lifecycle costs, downtime impact, and available technical expertise ensures optimized resource allocation and maximized operational efficiency. Implementing predictive analytics and condition-monitoring tools further refines decision-making between general upkeep and specialized service interventions.

Future Trends in Maintenance Practices

General maintenance is evolving towards increased automation and the integration of IoT sensors for real-time condition monitoring, enabling predictive approaches that reduce downtime and extend asset life. Specialized maintenance is adopting advanced analytics and AI-driven diagnostics to enhance precision in complex systems such as aerospace and medical equipment. Future trends highlight a convergence where general and specialized maintenance leverage digital twins and machine learning to optimize performance and support proactive decision-making across industries.

General Maintenance vs Specialized Maintenance Infographic

jobdiv.com

jobdiv.com