Line Maintenance focuses on routine and quick repairs performed on an aircraft while it is on the ground between flights, ensuring it remains airworthy and ready for immediate service. Base Maintenance involves more extensive inspections, overhauls, and repairs conducted in a hangar setting, often requiring longer downtime and specialized equipment. Differentiating these two types of maintenance optimizes scheduling, cost management, and overall aircraft reliability.

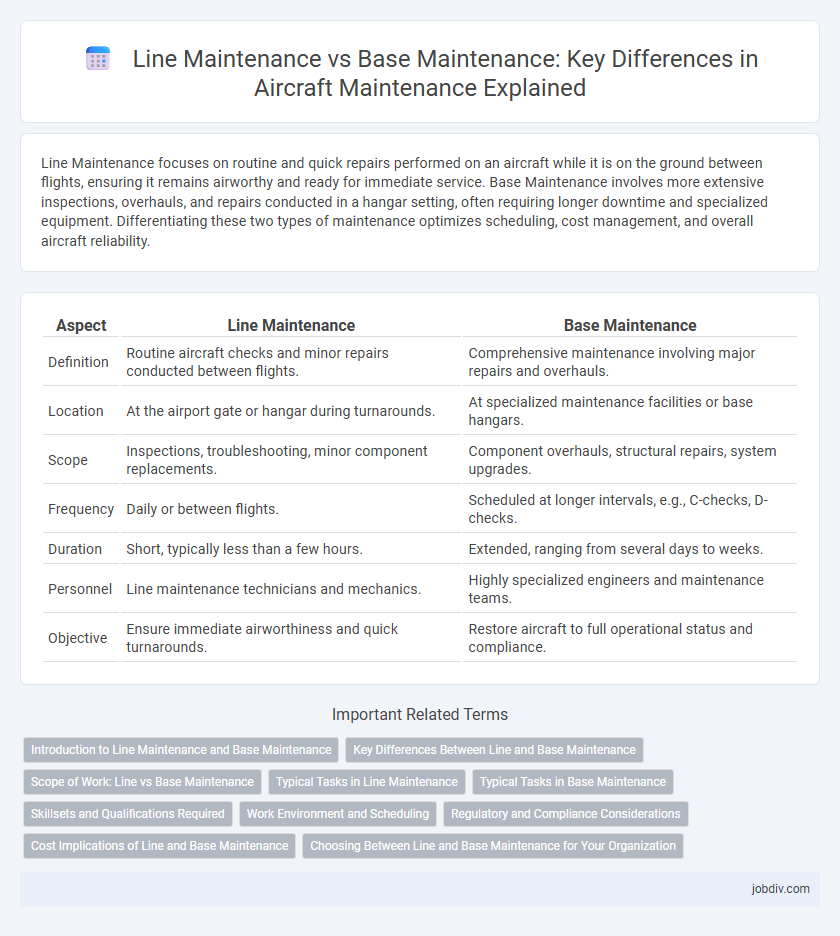

Table of Comparison

| Aspect | Line Maintenance | Base Maintenance |

|---|---|---|

| Definition | Routine aircraft checks and minor repairs conducted between flights. | Comprehensive maintenance involving major repairs and overhauls. |

| Location | At the airport gate or hangar during turnarounds. | At specialized maintenance facilities or base hangars. |

| Scope | Inspections, troubleshooting, minor component replacements. | Component overhauls, structural repairs, system upgrades. |

| Frequency | Daily or between flights. | Scheduled at longer intervals, e.g., C-checks, D-checks. |

| Duration | Short, typically less than a few hours. | Extended, ranging from several days to weeks. |

| Personnel | Line maintenance technicians and mechanics. | Highly specialized engineers and maintenance teams. |

| Objective | Ensure immediate airworthiness and quick turnarounds. | Restore aircraft to full operational status and compliance. |

Introduction to Line Maintenance and Base Maintenance

Line Maintenance involves routine checks, minor repairs, and troubleshooting performed on an aircraft between flights to ensure operational safety and compliance with aviation regulations. Base Maintenance encompasses comprehensive inspections, major repairs, and overhauls conducted at a hangar or maintenance facility, often requiring extensive downtime. Both maintenance types are essential for aircraft airworthiness, with Line Maintenance addressing immediate operational needs and Base Maintenance focusing on long-term reliability.

Key Differences Between Line and Base Maintenance

Line maintenance involves routine, quick inspections and minor repairs performed on an aircraft while it is on the ground between flights. Base maintenance encompasses comprehensive checks, heavy repairs, and overhauls typically conducted in a hangar, requiring the aircraft to be out of service for extended periods. The primary differences lie in scope, location, duration, and complexity, where line maintenance ensures operational safety during daily operations, and base maintenance focuses on in-depth system evaluations and refurbishments.

Scope of Work: Line vs Base Maintenance

Line maintenance involves routine inspections, minor repairs, and defect rectifications performed on aircraft between flights to ensure immediate airworthiness. Base maintenance encompasses comprehensive checks, major repairs, overhauls, and modifications conducted at specialized facilities, often requiring aircraft to be taken out of service for extended periods. The scope of line maintenance focuses on quick turnaround tasks essential for daily flight operations, while base maintenance addresses in-depth structural and system evaluations ensuring long-term aircraft reliability.

Typical Tasks in Line Maintenance

Typical tasks in line maintenance include routine inspections, minor repairs, and troubleshooting to ensure aircraft readiness between flights. These tasks often involve daily checks, tire changes, fluid replenishment, and addressing minor system faults to maintain operational safety. Line maintenance is performed on the tarmac with the goal of minimizing aircraft downtime and supporting continuous flight schedules.

Typical Tasks in Base Maintenance

Typical tasks in base maintenance include extensive inspections, heavy repairs, structural modifications, and major component overhauls that require specialized equipment and facilities. These activities often involve comprehensive checks of engines, landing gear, airframe, and avionics systems to ensure airworthiness and compliance with regulatory standards. Base maintenance is typically scheduled less frequently than line maintenance but is crucial for the long-term safety and performance of the aircraft.

Skillsets and Qualifications Required

Line maintenance technicians require skills in routine aircraft inspections, troubleshooting minor faults, and quick repairs to ensure aircraft readiness for daily operations. Base maintenance technicians possess advanced qualifications, including in-depth knowledge of aircraft systems, structural repairs, and the ability to perform extensive overhauls and modifications. Certification standards vary, with line maintenance typically requiring basic licenses such as an Aircraft Maintenance Technician (AMT) license, while base maintenance demands specialized endorsements and often higher-level engineering qualifications.

Work Environment and Scheduling

Line Maintenance takes place on the airport ramp or gate, offering a fast-paced work environment with immediate response to aircraft needs between flights. Base Maintenance occurs in a hangar or dedicated facility, allowing a controlled setting for in-depth inspections and extensive repairs. Scheduling for Line Maintenance is highly dynamic to minimize aircraft downtime, whereas Base Maintenance follows planned schedules aligned with maintenance cycles.

Regulatory and Compliance Considerations

Line Maintenance primarily operates under strict regulations concerning immediate aircraft safety and airworthiness, requiring rapid compliance with daily operational checks and minor repairs as mandated by aviation authorities such as the FAA and EASA. Base Maintenance involves comprehensive inspections, overhauls, and modifications that must adhere to more extensive regulatory frameworks, including compliance with maintenance program requirements, certification standards, and detailed record-keeping to ensure long-term aircraft reliability and safety. Both maintenance types demand rigorous adherence to regulatory documentation, personnel certification, and approved maintenance organization (AMO) standards to ensure full compliance and operational legitimacy.

Cost Implications of Line and Base Maintenance

Line maintenance typically involves routine inspections, minor repairs, and troubleshooting tasks performed quickly at airport gates or hangars, resulting in lower immediate costs but higher frequency expenses due to repeated interventions. Base maintenance encompasses extensive, scheduled overhauls and major repairs conducted in specialized facilities, incurring higher upfront costs but reducing overall lifecycle expenses through comprehensive inspections and component replacements. Cost implications of balancing line and base maintenance strategies are critical for optimizing aircraft availability and minimizing total maintenance expenditures in airline operations.

Choosing Between Line and Base Maintenance for Your Organization

Choosing between line maintenance and base maintenance depends on your organization's operational needs, budget, and aircraft utilization. Line maintenance involves routine checks and minor repairs performed on the aircraft between flights, ensuring quick turnaround times and minimal downtime. Base maintenance covers comprehensive inspections, overhauls, and major repairs requiring specialized facilities and extended aircraft grounding, making it suitable for scheduled heavy maintenance cycles.

Line Maintenance vs Base Maintenance Infographic

jobdiv.com

jobdiv.com