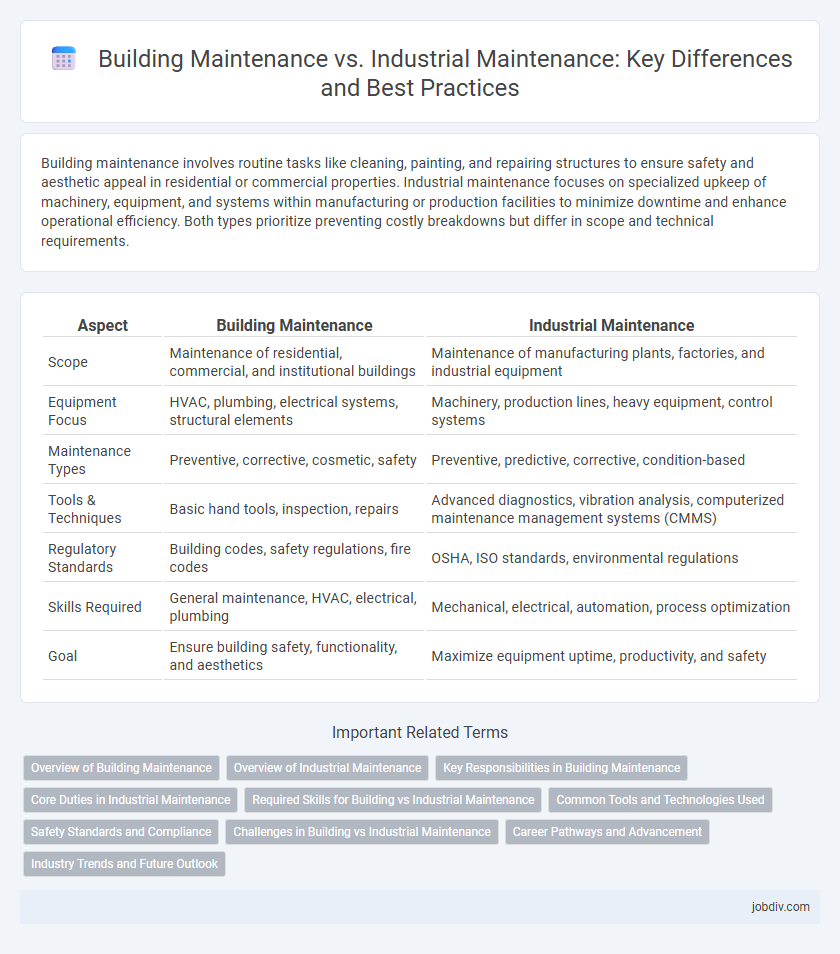

Building maintenance involves routine tasks like cleaning, painting, and repairing structures to ensure safety and aesthetic appeal in residential or commercial properties. Industrial maintenance focuses on specialized upkeep of machinery, equipment, and systems within manufacturing or production facilities to minimize downtime and enhance operational efficiency. Both types prioritize preventing costly breakdowns but differ in scope and technical requirements.

Table of Comparison

| Aspect | Building Maintenance | Industrial Maintenance |

|---|---|---|

| Scope | Maintenance of residential, commercial, and institutional buildings | Maintenance of manufacturing plants, factories, and industrial equipment |

| Equipment Focus | HVAC, plumbing, electrical systems, structural elements | Machinery, production lines, heavy equipment, control systems |

| Maintenance Types | Preventive, corrective, cosmetic, safety | Preventive, predictive, corrective, condition-based |

| Tools & Techniques | Basic hand tools, inspection, repairs | Advanced diagnostics, vibration analysis, computerized maintenance management systems (CMMS) |

| Regulatory Standards | Building codes, safety regulations, fire codes | OSHA, ISO standards, environmental regulations |

| Skills Required | General maintenance, HVAC, electrical, plumbing | Mechanical, electrical, automation, process optimization |

| Goal | Ensure building safety, functionality, and aesthetics | Maximize equipment uptime, productivity, and safety |

Overview of Building Maintenance

Building maintenance involves routine inspections, repairs, and upkeep of residential and commercial properties to ensure safety, functionality, and aesthetic appeal. Key tasks include HVAC system servicing, electrical and plumbing maintenance, and structural repairs to prevent deterioration and extend building lifespan. Effective building maintenance reduces operational costs and enhances occupant comfort by minimizing unexpected breakdowns and improving energy efficiency.

Overview of Industrial Maintenance

Industrial maintenance involves the systematic inspection, repair, and upkeep of machinery, equipment, and infrastructure within manufacturing plants and factories. It ensures optimal operational efficiency, reduces downtime, and extends the lifespan of complex industrial systems. Key activities include predictive maintenance, equipment calibration, and compliance with safety standards specific to industrial environments.

Key Responsibilities in Building Maintenance

Building maintenance primarily involves tasks such as routine inspections, repair of HVAC systems, plumbing upkeep, electrical safety checks, and preventive maintenance to ensure structural integrity and occupant safety. Maintenance crews handle cleaning, painting, and managing building automation systems to optimize energy efficiency and comfort. Key responsibilities also include compliance with safety regulations, timely response to repair requests, and coordination with contractors for major repairs or renovations.

Core Duties in Industrial Maintenance

Core duties in industrial maintenance include the regular inspection, repair, and upkeep of machinery, equipment, and production systems to ensure operational efficiency and minimize downtime. Technicians perform preventive maintenance, troubleshoot mechanical and electrical failures, and manage complex industrial control systems. These tasks differ from building maintenance, which primarily focuses on structural upkeep, HVAC systems, and general facility repairs.

Required Skills for Building vs Industrial Maintenance

Building maintenance requires skills in HVAC systems, plumbing, electrical wiring, and carpentry, with an emphasis on tenant safety and regulatory compliance. Industrial maintenance demands expertise in machinery repair, robotics, predictive maintenance technologies, and industrial safety protocols. Both fields prioritize problem-solving and preventative maintenance, but industrial maintenance requires advanced knowledge of automation and heavy equipment operation.

Common Tools and Technologies Used

Building maintenance commonly relies on tools such as hand tools, power drills, HVAC diagnostic equipment, and electrical testing devices to ensure structural integrity and system functionality. Industrial maintenance, however, utilizes more specialized technologies including PLC programming tools, vibration analysis instruments, thermal imaging cameras, and predictive maintenance software to monitor machinery and optimize operational efficiency. Both fields increasingly integrate IoT sensors and CMMS (Computerized Maintenance Management Systems) for real-time monitoring and data-driven decision-making.

Safety Standards and Compliance

Building maintenance emphasizes safety standards that protect occupants and comply with local building codes, fire regulations, and occupational health guidelines. Industrial maintenance requires adherence to stringent safety protocols involving heavy machinery, hazardous materials, and regulatory frameworks such as OSHA and EPA standards. Ensuring compliance in both sectors reduces risk of accidents, legal penalties, and operational downtime.

Challenges in Building vs Industrial Maintenance

Building maintenance faces challenges such as managing diverse occupant needs, aging infrastructure, and adhering to strict safety codes. Industrial maintenance requires addressing complex machinery upkeep, minimizing production downtime, and ensuring compliance with rigorous workplace safety standards. Both domains demand specialized skills, but industrial maintenance typically involves higher technical complexity and risk management.

Career Pathways and Advancement

Building maintenance careers typically emphasize skills in HVAC, electrical systems, and plumbing, offering advancement through certifications like EPA Technician or OSHA Safety Specialist. Industrial maintenance pathways require expertise in automated machinery, robotics, and predictive maintenance technologies, with career growth often linked to training in PLC programming and industrial safety standards. Both fields provide opportunities for specialization and leadership roles, but industrial maintenance generally demands higher technical proficiency and offers faster progression in manufacturing or production environments.

Industry Trends and Future Outlook

Building maintenance primarily emphasizes preventive measures, energy efficiency, and smart technology integration to enhance facility longevity and occupant comfort. Industrial maintenance trends focus on predictive analytics, automation, and IoT-based monitoring to minimize downtime and optimize production processes. Future outlooks indicate an increasing convergence of AI-driven maintenance systems across both sectors, driving cost reduction and operational efficiency.

Building Maintenance vs Industrial Maintenance Infographic

jobdiv.com

jobdiv.com