Shutdown maintenance involves halting operations entirely to perform extensive inspections, repairs, or upgrades, often requiring careful planning and significant downtime. Routine maintenance consists of regular, scheduled tasks aimed at preventing equipment failure and ensuring optimal performance without interrupting normal operations. Both types are essential for maximizing the lifespan and reliability of assets, with shutdown maintenance addressing deeper issues and routine maintenance focusing on ongoing upkeep.

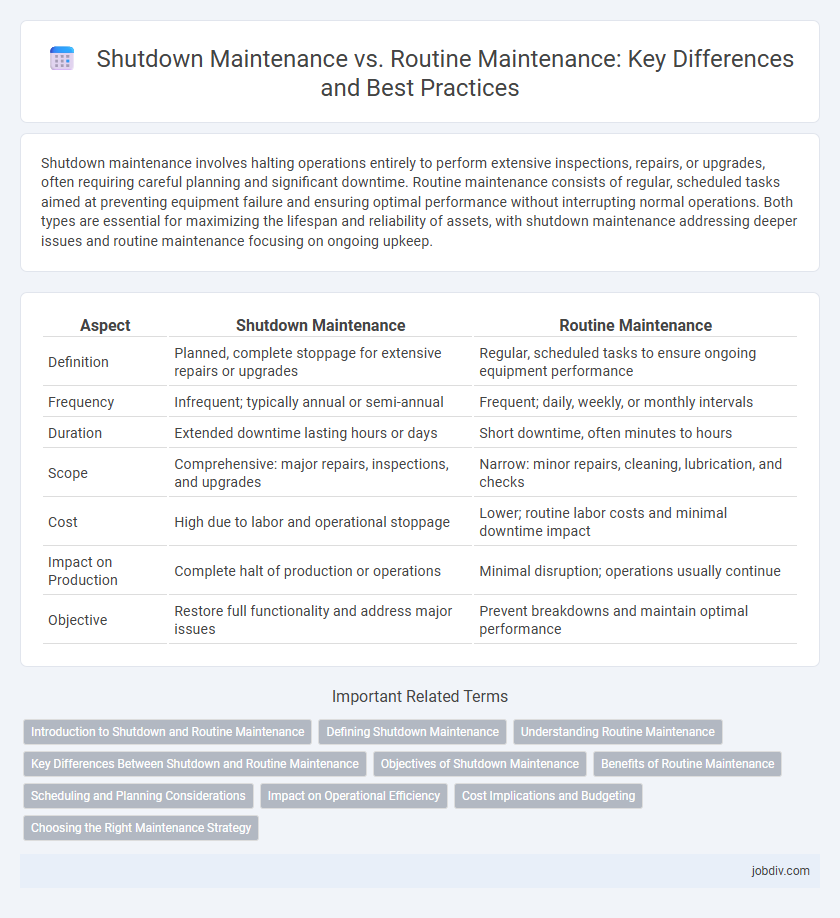

Table of Comparison

| Aspect | Shutdown Maintenance | Routine Maintenance |

|---|---|---|

| Definition | Planned, complete stoppage for extensive repairs or upgrades | Regular, scheduled tasks to ensure ongoing equipment performance |

| Frequency | Infrequent; typically annual or semi-annual | Frequent; daily, weekly, or monthly intervals |

| Duration | Extended downtime lasting hours or days | Short downtime, often minutes to hours |

| Scope | Comprehensive: major repairs, inspections, and upgrades | Narrow: minor repairs, cleaning, lubrication, and checks |

| Cost | High due to labor and operational stoppage | Lower; routine labor costs and minimal downtime impact |

| Impact on Production | Complete halt of production or operations | Minimal disruption; operations usually continue |

| Objective | Restore full functionality and address major issues | Prevent breakdowns and maintain optimal performance |

Introduction to Shutdown and Routine Maintenance

Shutdown maintenance involves planned, extensive equipment or system stoppages to perform thorough inspections, repairs, and upgrades, minimizing unplanned downtime and enhancing long-term reliability. Routine maintenance consists of regular, scheduled tasks such as lubrication, cleaning, and minor adjustments designed to sustain optimal operational performance and prevent unexpected failures. Both maintenance types are critical for maintaining asset integrity and operational efficiency in industrial and manufacturing environments.

Defining Shutdown Maintenance

Shutdown maintenance refers to a planned and complete halt of operations to perform extensive repairs, inspections, or upgrades on machinery and equipment. This type of maintenance is critical for addressing major issues that cannot be resolved during normal production schedules, ensuring safety and operational efficiency. Shutdown maintenance often involves detailed planning, coordination, and resource allocation to minimize downtime and restore full functionality.

Understanding Routine Maintenance

Routine maintenance involves regular, scheduled tasks designed to prevent equipment failure and ensure optimal performance by inspecting, cleaning, lubricating, and adjusting machinery. Unlike shutdown maintenance, which requires halting operations for major repairs or overhauls, routine maintenance is performed during normal operation to minimize downtime and extend asset lifespan. Effective routine maintenance reduces unexpected breakdowns, lowers repair costs, and improves overall equipment reliability.

Key Differences Between Shutdown and Routine Maintenance

Shutdown maintenance involves planned, extensive work requiring complete equipment or system stoppage, often scheduled during off-peak periods to minimize operational disruption. Routine maintenance consists of regular, smaller-scale tasks performed while equipment is running or during brief pauses to ensure ongoing functionality and prevent failures. Key differences include scale, duration, and impact on production, with shutdown maintenance addressing major repairs or upgrades, whereas routine maintenance focuses on ongoing upkeep and inspections.

Objectives of Shutdown Maintenance

Shutdown maintenance aims to perform extensive repairs, upgrades, and inspections that cannot be completed during routine operations, ensuring long-term equipment reliability and safety. It minimizes unexpected breakdowns by addressing potential issues systematically when the facility is not operational. Effective shutdown maintenance enhances operational efficiency by restoring or improving machinery performance and compliance with safety standards.

Benefits of Routine Maintenance

Routine maintenance improves equipment reliability by identifying and resolving minor issues before they escalate into major problems requiring shutdown maintenance. It extends asset lifespan, reduces unexpected downtime, and optimizes operational efficiency through scheduled inspections and timely repairs. Consistent routine maintenance lowers overall maintenance costs by preventing costly emergency interventions and maintaining steady production flow.

Scheduling and Planning Considerations

Shutdown maintenance requires extensive scheduling and planning to minimize downtime and coordinate multiple teams, often involving long lead times for procurement and task sequencing. Routine maintenance involves more flexible scheduling, typically planned around regular operational cycles with predictable, smaller-scale tasks. Effective planning for shutdown maintenance includes detailed resource allocation and risk management, whereas routine maintenance emphasizes adherence to maintenance intervals and immediate operational needs.

Impact on Operational Efficiency

Shutdown maintenance requires halting operations entirely, leading to extended downtime that significantly disrupts production flow and reduces overall operational efficiency. Routine maintenance occurs during scheduled intervals without stopping all systems, allowing continuous operation and minimizing negative impacts on productivity. Prioritizing routine maintenance helps maintain high efficiency by preventing unexpected breakdowns and costly shutdowns.

Cost Implications and Budgeting

Shutdown maintenance involves halting operations for extensive repairs or upgrades, often leading to higher immediate costs due to labor, parts, and lost production. Routine maintenance, performed regularly without stopping production, typically incurs lower ongoing expenses and helps prevent costly breakdowns. Budgeting for shutdown maintenance requires allocating significant funds in advance, while routine maintenance budgets emphasize consistent, manageable expenditures.

Choosing the Right Maintenance Strategy

Selecting the right maintenance strategy hinges on balancing the urgency of equipment downtime with long-term operational efficiency. Shutdown maintenance involves planned halts for comprehensive repairs, minimizing unexpected failures but impacting productivity, while routine maintenance emphasizes regular inspections and minor fixes to sustain consistent performance and prevent major breakdowns. Analyzing equipment criticality, operational schedules, and cost implications guides organizations in optimizing maintenance approaches for maximum asset reliability and reduced operational disruptions.

Shutdown Maintenance vs Routine Maintenance Infographic

jobdiv.com

jobdiv.com