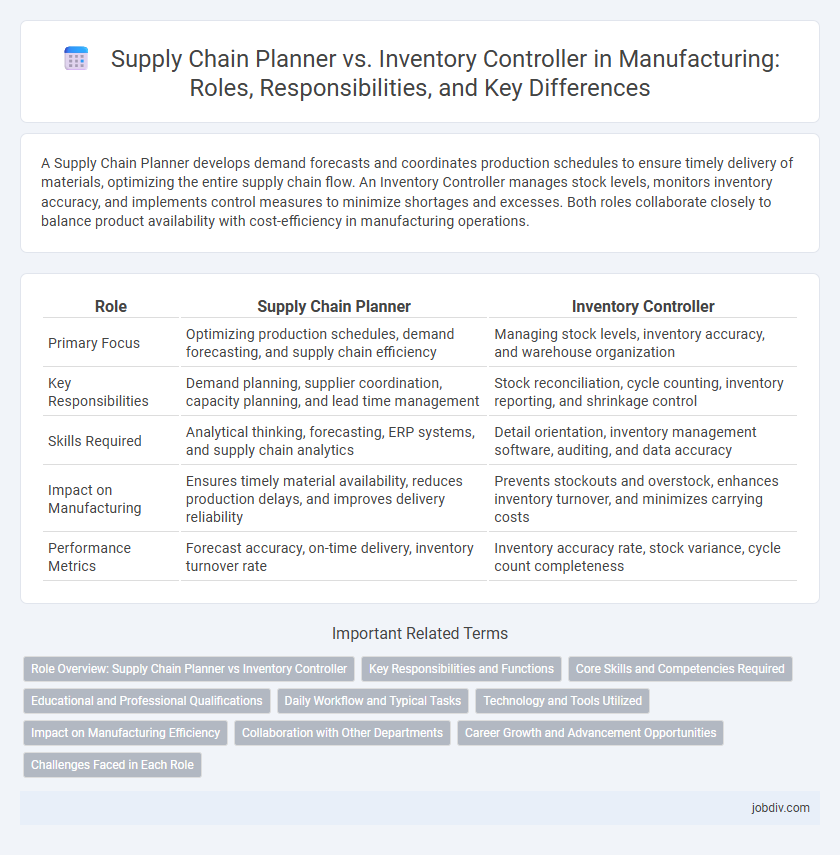

A Supply Chain Planner develops demand forecasts and coordinates production schedules to ensure timely delivery of materials, optimizing the entire supply chain flow. An Inventory Controller manages stock levels, monitors inventory accuracy, and implements control measures to minimize shortages and excesses. Both roles collaborate closely to balance product availability with cost-efficiency in manufacturing operations.

Table of Comparison

| Role | Supply Chain Planner | Inventory Controller |

|---|---|---|

| Primary Focus | Optimizing production schedules, demand forecasting, and supply chain efficiency | Managing stock levels, inventory accuracy, and warehouse organization |

| Key Responsibilities | Demand planning, supplier coordination, capacity planning, and lead time management | Stock reconciliation, cycle counting, inventory reporting, and shrinkage control |

| Skills Required | Analytical thinking, forecasting, ERP systems, and supply chain analytics | Detail orientation, inventory management software, auditing, and data accuracy |

| Impact on Manufacturing | Ensures timely material availability, reduces production delays, and improves delivery reliability | Prevents stockouts and overstock, enhances inventory turnover, and minimizes carrying costs |

| Performance Metrics | Forecast accuracy, on-time delivery, inventory turnover rate | Inventory accuracy rate, stock variance, cycle count completeness |

Role Overview: Supply Chain Planner vs Inventory Controller

Supply Chain Planners focus on forecasting demand, production scheduling, and coordinating logistics to optimize the entire supply chain flow. Inventory Controllers manage stock levels, track inventory accuracy, perform cycle counts, and ensure materials are available to meet production needs without overstocking. Both roles aim to balance supply and demand, but Planners adopt a strategic approach while Controllers handle operational inventory management.

Key Responsibilities and Functions

A Supply Chain Planner optimizes production schedules, forecasts demand, and coordinates procurement to ensure seamless material flow across manufacturing processes. Inventory Controllers monitor stock levels, perform regular audits, manage reorder points, and prevent excess or obsolete inventory to maintain cost efficiency. Both roles collaborate to balance supply chain agility with inventory accuracy, boosting operational productivity and reducing downtime in manufacturing environments.

Core Skills and Competencies Required

Supply Chain Planners require strong analytical skills, demand forecasting expertise, and proficiency in supply chain management software to optimize production schedules and resource allocation. Inventory Controllers must excel in inventory tracking, accuracy in stock management, and knowledge of warehouse operations to maintain optimal inventory levels and minimize discrepancies. Both roles demand effective communication, problem-solving abilities, and attention to detail for seamless coordination between procurement, production, and distribution functions.

Educational and Professional Qualifications

A Supply Chain Planner typically holds a bachelor's degree in supply chain management, logistics, or industrial engineering, often complemented by certifications such as APICS CPIM or CSCP to enhance strategic planning skills. An Inventory Controller usually possesses a background in business administration or finance, with a focus on inventory management, and benefits from professional qualifications like Certified Inventory Professional (CIP) or Six Sigma for process optimization. Both roles require strong analytical abilities, but the Supply Chain Planner emphasizes forecasting and demand planning, while the Inventory Controller specializes in stock accuracy and warehouse operations.

Daily Workflow and Typical Tasks

Supply Chain Planners focus on demand forecasting, production scheduling, and coordinating raw material procurement to optimize inventory levels and ensure timely product delivery. Inventory Controllers handle stock audits, monitor inventory accuracy, and manage reorder points to prevent stockouts or overstock situations. Daily workflows for Supply Chain Planners involve analyzing market trends and adjusting supply plans, while Inventory Controllers concentrate on real-time inventory tracking and resolving discrepancies.

Technology and Tools Utilized

Supply Chain Planners leverage advanced forecasting software, demand planning tools, and integrated ERP systems to optimize production schedules and coordinate supplier deliveries. Inventory Controllers utilize barcode scanning technology, automated inventory management systems, and real-time data analytics platforms to maintain accurate stock levels and minimize discrepancies. Both roles depend on technologies such as cloud computing and AI-driven insights to enhance efficiency and responsiveness within manufacturing operations.

Impact on Manufacturing Efficiency

Supply chain planners enhance manufacturing efficiency by optimizing production schedules and ensuring timely availability of raw materials, which reduces downtime and aligns output with demand forecasts. Inventory controllers maintain accurate stock levels, preventing excess inventory and minimizing storage costs, which supports smooth production flow and cost-effective resource utilization. Both roles are crucial for balancing supply with production needs, directly impacting operational efficiency and manufacturing output quality.

Collaboration with Other Departments

Supply Chain Planners collaborate closely with production, procurement, and logistics teams to ensure demand forecasts align with manufacturing schedules, optimizing resource allocation. Inventory Controllers work alongside warehouse and finance departments to maintain accurate stock levels, minimize carrying costs, and prevent stockouts or excess inventory. Effective communication between these roles enhances operational efficiency and supports seamless production workflows.

Career Growth and Advancement Opportunities

Supply Chain Planners typically experience faster career growth due to their strategic role in demand forecasting, production scheduling, and coordination across multiple departments, which develops advanced analytical and management skills. Inventory Controllers often advance by specializing in inventory optimization, cost control, and compliance with regulatory standards, making them critical for operational efficiency and risk management. Career advancement for Supply Chain Planners often leads to roles like Supply Chain Manager or Operations Director, while Inventory Controllers may progress to Inventory Manager or Logistics Manager positions.

Challenges Faced in Each Role

Supply Chain Planners encounter challenges such as demand forecasting inaccuracies, supplier delays, and balancing production schedules with fluctuating market demands. Inventory Controllers face difficulties in maintaining optimal stock levels, preventing stockouts or overstock situations, and ensuring accurate inventory data amidst complex warehouse operations. Both roles require precise coordination to minimize costs and maximize operational efficiency within manufacturing supply chains.

Supply Chain Planner vs Inventory Controller Infographic

jobdiv.com

jobdiv.com