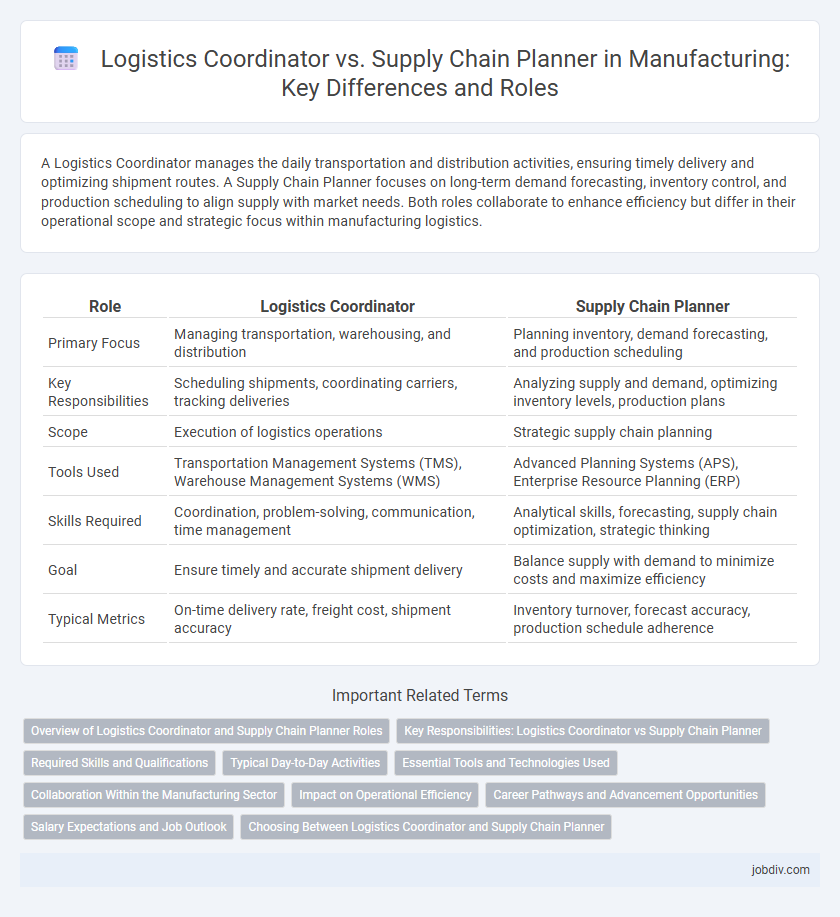

A Logistics Coordinator manages the daily transportation and distribution activities, ensuring timely delivery and optimizing shipment routes. A Supply Chain Planner focuses on long-term demand forecasting, inventory control, and production scheduling to align supply with market needs. Both roles collaborate to enhance efficiency but differ in their operational scope and strategic focus within manufacturing logistics.

Table of Comparison

| Role | Logistics Coordinator | Supply Chain Planner |

|---|---|---|

| Primary Focus | Managing transportation, warehousing, and distribution | Planning inventory, demand forecasting, and production scheduling |

| Key Responsibilities | Scheduling shipments, coordinating carriers, tracking deliveries | Analyzing supply and demand, optimizing inventory levels, production plans |

| Scope | Execution of logistics operations | Strategic supply chain planning |

| Tools Used | Transportation Management Systems (TMS), Warehouse Management Systems (WMS) | Advanced Planning Systems (APS), Enterprise Resource Planning (ERP) |

| Skills Required | Coordination, problem-solving, communication, time management | Analytical skills, forecasting, supply chain optimization, strategic thinking |

| Goal | Ensure timely and accurate shipment delivery | Balance supply with demand to minimize costs and maximize efficiency |

| Typical Metrics | On-time delivery rate, freight cost, shipment accuracy | Inventory turnover, forecast accuracy, production schedule adherence |

Overview of Logistics Coordinator and Supply Chain Planner Roles

Logistics Coordinators manage the efficient flow of materials and products from suppliers to production facilities and distribution centers, focusing on transportation scheduling, shipment tracking, and inventory control. Supply Chain Planners analyze demand forecasts and production capacity to develop procurement and distribution strategies that optimize inventory levels and minimize costs. Both roles are critical in manufacturing, with Logistics Coordinators ensuring operational execution while Supply Chain Planners drive strategic supply chain optimization.

Key Responsibilities: Logistics Coordinator vs Supply Chain Planner

Logistics Coordinators manage the efficient transportation and distribution of goods, ensuring timely delivery, tracking shipments, and coordinating with carriers and warehouses. Supply Chain Planners focus on demand forecasting, inventory management, and production scheduling to optimize the supply chain flow and meet customer requirements. Both roles require collaboration with suppliers and internal teams, but Logistics Coordinators emphasize operational execution while Supply Chain Planners concentrate on strategic planning and resource allocation.

Required Skills and Qualifications

Logistics Coordinators require strong organizational skills, proficiency in inventory management software, and expertise in transportation logistics to ensure timely delivery and efficient warehouse operations. Supply Chain Planners need advanced analytical abilities, proficiency in demand forecasting tools, and knowledge of production scheduling to optimize supply chain processes and reduce costs. Both roles benefit from excellent communication skills and a solid understanding of manufacturing workflows to coordinate resources effectively.

Typical Day-to-Day Activities

Logistics Coordinators manage daily shipment schedules, track inventory levels, and coordinate with carriers to ensure timely delivery, emphasizing operational execution and real-time problem-solving. Supply Chain Planners focus on demand forecasting, inventory replenishment, and production scheduling to optimize resource allocation and meet long-term business objectives. Both roles require collaboration with procurement, production, and distribution teams to maintain supply chain efficiency and minimize disruptions.

Essential Tools and Technologies Used

Logistics Coordinators primarily utilize transportation management systems (TMS), warehouse management systems (WMS), and real-time tracking technologies to optimize shipment schedules and inventory flow. Supply Chain Planners rely heavily on advanced demand forecasting software, ERP systems, and data analytics platforms to enhance production planning and resource allocation. Both roles integrate IoT devices and cloud-based solutions to improve visibility and coordination across the supply chain network.

Collaboration Within the Manufacturing Sector

Logistics Coordinators and Supply Chain Planners collaborate closely within the manufacturing sector to streamline production schedules and optimize inventory management. Logistics Coordinators focus on the transportation and warehousing of raw materials and finished goods, ensuring timely delivery and minimizing delays on the shop floor. Supply Chain Planners analyze demand forecasts and coordinate with suppliers to balance supply availability, reducing production downtime and improving overall operational efficiency.

Impact on Operational Efficiency

Logistics Coordinators manage the timely movement and storage of materials, directly reducing delays and minimizing inventory holding costs, which enhances operational efficiency. Supply Chain Planners focus on demand forecasting and production scheduling, optimizing resource allocation and ensuring smooth workflow across the supply chain. The combined efforts of both roles result in streamlined operations, reduced lead times, and improved overall manufacturing productivity.

Career Pathways and Advancement Opportunities

Logistics Coordinators typically start with roles in inventory management or transportation coordination, advancing toward operations management or logistics analyst positions that emphasize process optimization. Supply Chain Planners often follow a trajectory involving demand forecasting and production planning, progressing into senior planner or supply chain manager roles with heightened strategic responsibilities. Career advancement in both pathways benefits from proficiency in ERP systems, data analytics, and cross-functional collaboration within manufacturing environments.

Salary Expectations and Job Outlook

Logistics Coordinators in manufacturing typically earn between $45,000 and $60,000 annually, with growth driven by demand for efficient transportation and inventory management. Supply Chain Planners command higher salaries, ranging from $55,000 to $75,000, reflecting their strategic role in demand forecasting and production scheduling. Job outlook for Supply Chain Planners is stronger due to increasing complexity in supply networks, while Logistics Coordinators remain essential for operational execution and cost control.

Choosing Between Logistics Coordinator and Supply Chain Planner

Choosing between a Logistics Coordinator and a Supply Chain Planner depends on the scope of responsibilities and strategic involvement within manufacturing operations. A Logistics Coordinator typically handles day-to-day transportation, inventory management, and order fulfillment, ensuring efficient movement of materials. In contrast, a Supply Chain Planner focuses on demand forecasting, production scheduling, and long-term supply chain optimization to align manufacturing output with market needs.

Logistics Coordinator vs Supply Chain Planner Infographic

jobdiv.com

jobdiv.com