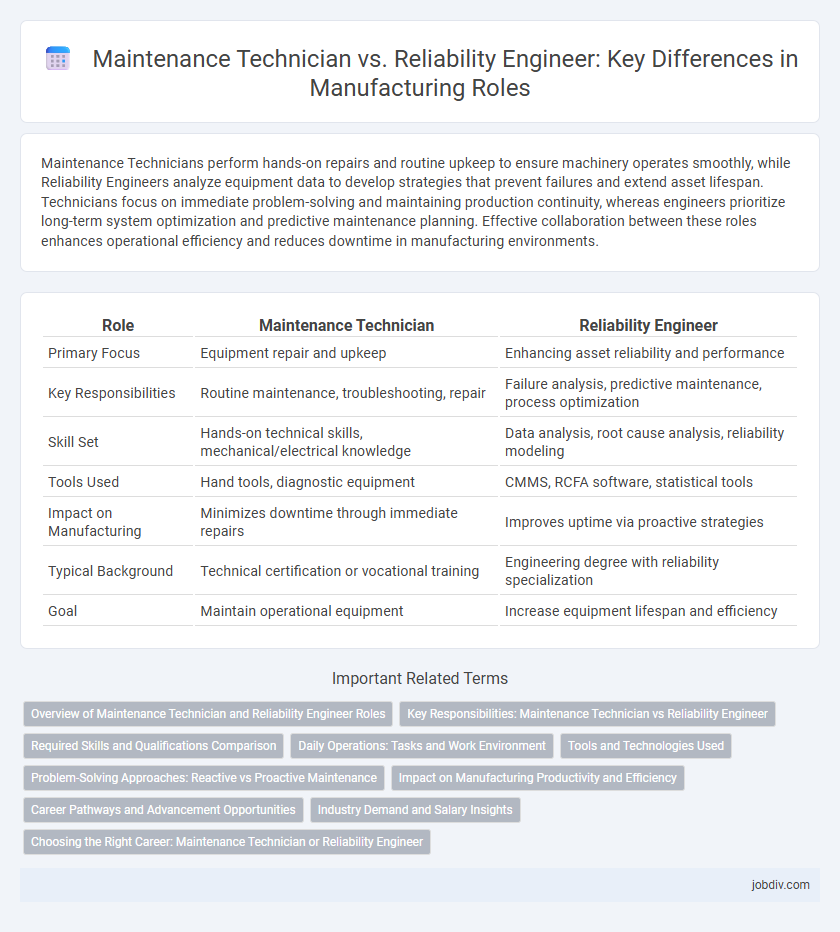

Maintenance Technicians perform hands-on repairs and routine upkeep to ensure machinery operates smoothly, while Reliability Engineers analyze equipment data to develop strategies that prevent failures and extend asset lifespan. Technicians focus on immediate problem-solving and maintaining production continuity, whereas engineers prioritize long-term system optimization and predictive maintenance planning. Effective collaboration between these roles enhances operational efficiency and reduces downtime in manufacturing environments.

Table of Comparison

| Role | Maintenance Technician | Reliability Engineer |

|---|---|---|

| Primary Focus | Equipment repair and upkeep | Enhancing asset reliability and performance |

| Key Responsibilities | Routine maintenance, troubleshooting, repair | Failure analysis, predictive maintenance, process optimization |

| Skill Set | Hands-on technical skills, mechanical/electrical knowledge | Data analysis, root cause analysis, reliability modeling |

| Tools Used | Hand tools, diagnostic equipment | CMMS, RCFA software, statistical tools |

| Impact on Manufacturing | Minimizes downtime through immediate repairs | Improves uptime via proactive strategies |

| Typical Background | Technical certification or vocational training | Engineering degree with reliability specialization |

| Goal | Maintain operational equipment | Increase equipment lifespan and efficiency |

Overview of Maintenance Technician and Reliability Engineer Roles

Maintenance Technicians perform routine inspections, troubleshoot equipment issues, and execute repairs to ensure continuous production and minimize downtime. Reliability Engineers analyze asset data, develop predictive maintenance strategies, and implement reliability improvement plans to optimize equipment performance and extend lifecycle. Both roles are essential in manufacturing for maintaining operational efficiency, with Technicians focusing on hands-on repairs and Engineers driving data-driven maintenance optimization.

Key Responsibilities: Maintenance Technician vs Reliability Engineer

Maintenance Technicians are primarily responsible for performing routine inspections, troubleshooting equipment issues, and executing preventative maintenance to ensure machinery operates efficiently. Reliability Engineers focus on analyzing failure data, developing predictive maintenance strategies, and optimizing asset performance to minimize downtime and extend equipment life. Both roles collaborate to enhance operational reliability but differ in scope, with Maintenance Technicians handling hands-on repairs and Reliability Engineers driving data-driven maintenance improvements.

Required Skills and Qualifications Comparison

Maintenance Technicians require hands-on skills in equipment repair, mechanical systems, and troubleshooting, often necessitating certifications like HVAC or electrical licenses and a technical diploma. Reliability Engineers need advanced knowledge in data analysis, predictive maintenance, and reliability-centered maintenance (RCM) methodologies, typically holding a bachelor's degree in engineering or a related field along with expertise in software tools such as SAP or CMMS. Both roles emphasize problem-solving and communication, but Reliability Engineers focus more on strategic improvements and long-term asset performance optimization.

Daily Operations: Tasks and Work Environment

Maintenance Technicians perform routine inspections, equipment repairs, and troubleshoot mechanical issues to ensure smooth plant operations, typically working on the shop floor with hands-on tasks. Reliability Engineers analyze maintenance data, develop predictive maintenance strategies, and collaborate with cross-functional teams to enhance asset reliability, often operating within office settings supported by digital monitoring tools. Both roles are integral to minimizing downtime and optimizing production efficiency in manufacturing environments.

Tools and Technologies Used

Maintenance Technicians typically utilize diagnostic tools such as infrared thermography, vibration analyzers, and handheld multimeters to perform routine inspections and repairs on manufacturing equipment. Reliability Engineers leverage advanced software platforms like Computerized Maintenance Management Systems (CMMS), Root Cause Analysis (RCA) tools, and predictive analytics powered by IoT sensors to optimize asset performance and prevent failures. Both roles integrate technologies such as PLC programming and condition monitoring systems to ensure operational efficiency and minimize downtime on production lines.

Problem-Solving Approaches: Reactive vs Proactive Maintenance

Maintenance Technicians primarily engage in reactive maintenance by addressing equipment breakdowns as they occur, ensuring quick repairs to minimize downtime. Reliability Engineers implement proactive maintenance strategies by analyzing data trends and predicting potential failures to prevent disruptions and optimize asset performance. This shift from reactive to proactive approaches significantly enhances operational efficiency and reduces overall maintenance costs in manufacturing environments.

Impact on Manufacturing Productivity and Efficiency

Maintenance Technicians directly enhance manufacturing productivity by quickly diagnosing and repairing equipment faults, minimizing downtime and ensuring smooth operation of production lines. Reliability Engineers focus on optimizing asset performance through predictive maintenance strategies and failure analysis, leading to long-term efficiency improvements and reduced unexpected breakdowns. Together, their coordinated efforts drive higher overall equipment effectiveness (OEE) and continuous process improvement in manufacturing environments.

Career Pathways and Advancement Opportunities

Maintenance Technicians typically begin with hands-on roles focused on equipment repair and preventive maintenance, gaining technical skills through certifications such as EPA 608 or NIMS credentials, with advancement opportunities leading to supervisory positions or specialized technical roles. Reliability Engineers require a deeper understanding of data analysis, root cause failure analysis, and predictive maintenance techniques, often advancing through engineering degrees and certifications like CRE (Certified Reliability Engineer), progressing to roles in asset management, project leadership, or continuous improvement leadership. Career pathways diverge as Maintenance Technicians emphasize operational expertise while Reliability Engineers focus on strategic optimization, offering distinct advancement trajectories within manufacturing organizations.

Industry Demand and Salary Insights

Maintenance Technicians in manufacturing typically earn between $45,000 and $65,000 annually, with steady demand driven by the need for routine equipment upkeep and troubleshooting. Reliability Engineers command higher salaries, often ranging from $75,000 to over $100,000, reflecting their role in optimizing asset performance and minimizing downtime through predictive maintenance strategies. Industry demand for Reliability Engineers is growing faster due to increased adoption of data analytics and automation technologies aimed at enhancing operational efficiency.

Choosing the Right Career: Maintenance Technician or Reliability Engineer

Choosing between a Maintenance Technician and a Reliability Engineer career depends on skill sets and job focus. Maintenance Technicians specialize in hands-on equipment repair and routine maintenance processes, ensuring machinery operates efficiently on the shop floor. Reliability Engineers analyze data and implement predictive maintenance strategies to improve equipment longevity and reduce downtime, making them integral to long-term operational optimization in manufacturing environments.

Maintenance Technician vs Reliability Engineer Infographic

jobdiv.com

jobdiv.com