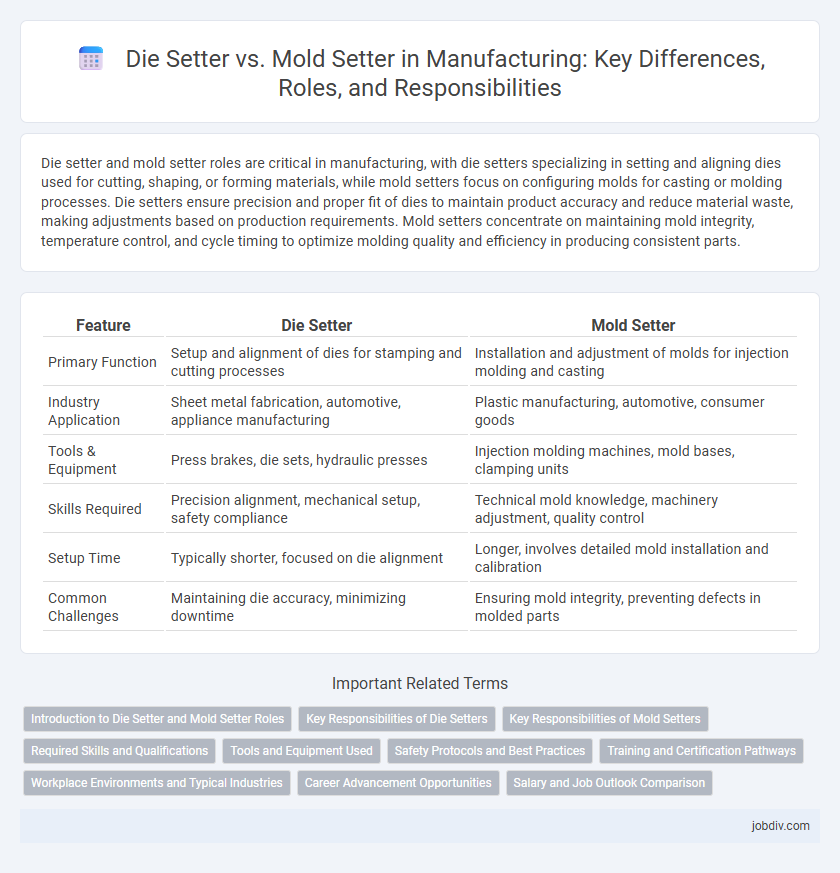

Die setter and mold setter roles are critical in manufacturing, with die setters specializing in setting and aligning dies used for cutting, shaping, or forming materials, while mold setters focus on configuring molds for casting or molding processes. Die setters ensure precision and proper fit of dies to maintain product accuracy and reduce material waste, making adjustments based on production requirements. Mold setters concentrate on maintaining mold integrity, temperature control, and cycle timing to optimize molding quality and efficiency in producing consistent parts.

Table of Comparison

| Feature | Die Setter | Mold Setter |

|---|---|---|

| Primary Function | Setup and alignment of dies for stamping and cutting processes | Installation and adjustment of molds for injection molding and casting |

| Industry Application | Sheet metal fabrication, automotive, appliance manufacturing | Plastic manufacturing, automotive, consumer goods |

| Tools & Equipment | Press brakes, die sets, hydraulic presses | Injection molding machines, mold bases, clamping units |

| Skills Required | Precision alignment, mechanical setup, safety compliance | Technical mold knowledge, machinery adjustment, quality control |

| Setup Time | Typically shorter, focused on die alignment | Longer, involves detailed mold installation and calibration |

| Common Challenges | Maintaining die accuracy, minimizing downtime | Ensuring mold integrity, preventing defects in molded parts |

Introduction to Die Setter and Mold Setter Roles

Die setters specialize in assembling, aligning, and maintaining dies used in metal stamping and forming processes to ensure precision and quality in manufacturing. Mold setters focus on installing, adjusting, and maintaining molds for injection molding and casting operations, crucial for producing accurate plastic or metal parts. Both roles require technical expertise in machinery setup and troubleshooting to optimize production efficiency and reduce downtime.

Key Responsibilities of Die Setters

Die Setters specialize in assembling, adjusting, and maintaining dies used in metal stamping or forming processes to ensure high precision and efficiency. Their key responsibilities include aligning die components, performing routine inspections for wear or damage, and troubleshooting mechanical issues to minimize downtime. Expertise in interpreting technical drawings and using precision measuring instruments is essential for accurate die setup and optimal production output.

Key Responsibilities of Mold Setters

Mold Setters specialize in installing, adjusting, and maintaining injection molds to ensure precise manufacturing processes and high-quality product output. Their key responsibilities include aligning molds accurately on injection molding machines, conducting routine inspections to detect wear or damage, and performing preventive maintenance to minimize downtime. Proficiency in interpreting technical drawings and collaborating with production teams to optimize mold performance is essential for Mold Setters in manufacturing environments.

Required Skills and Qualifications

Die setters require proficiency in blueprint reading, precision measurement tools, and mechanical aptitude to install and adjust dies for metal stamping or cutting processes. Mold setters must demonstrate skills in interpreting technical drawings, operating molding machines, and performing maintenance on molds to ensure optimal production quality. Both roles demand strong problem-solving abilities, manual dexterity, and familiarity with safety protocols in manufacturing environments.

Tools and Equipment Used

Die setters primarily use precision measuring instruments such as micrometers, calipers, and dial indicators to ensure accurate die alignment and setup, supported by hydraulic presses and specialized die-handling equipment. Mold setters rely on injection molding machines, hot runner systems, and mold temperature controllers, along with alignment tools like locating pins and clamps to secure and calibrate molds efficiently. Both roles utilize computer-aided measurement systems and CNC machines for enhanced precision and repeatability in tool setup processes.

Safety Protocols and Best Practices

Die setters and mold setters in manufacturing must rigorously follow safety protocols such as lockout/tagout procedures and personal protective equipment (PPE) usage to prevent accidents involving heavy machinery and sharp tools. Best practices include thorough training on equipment handling, regular maintenance checks, and adherence to standardized operating procedures specific to die and mold setup. Ensuring clear communication and workspace organization minimizes the risk of injuries and enhances overall operational efficiency.

Training and Certification Pathways

Die setter training emphasizes precision in aligning and assembling tooling components, often requiring certification in mechanical systems and CNC machinery operation to ensure competence in die maintenance. Mold setter certification pathways typically include specialized courses in mold installation, troubleshooting, and material handling, with a strong focus on injection molding processes and safety standards. Both roles benefit from apprenticeship programs and industry-recognized credentials such as those offered by the National Institute for Metalworking Skills (NIMS) for die setters and the Society of Plastics Engineers (SPE) for mold setters.

Workplace Environments and Typical Industries

Die setters predominantly work in heavy manufacturing environments, including automotive, aerospace, and metal fabrication industries, where precision in shaping and cutting metal dies is critical. Mold setters are typically employed in plastics manufacturing, packaging, and consumer goods industries, specializing in setting up and maintaining molds for injection molding or blow molding processes. Both roles require strong mechanical skills but differ in workplace settings, with die setters often in high-temperature, metal-intensive facilities and mold setters in cleaner, climate-controlled environments.

Career Advancement Opportunities

Die setters and mold setters both play critical roles in manufacturing, but die setters often have broader career advancement opportunities due to the complexity of working with metal forming tools for high-precision parts. Mold setters specialize in assembling and adjusting molds used in plastic injection processes, which can lead to roles in mold design and plastic part production management. Professionals who gain cross-functional expertise in both die and mold setting are highly valued, increasing their potential for supervisory or technical specialist positions within manufacturing plants.

Salary and Job Outlook Comparison

Die setters earn an average annual salary ranging from $35,000 to $50,000, while mold setters typically make between $38,000 and $55,000 depending on experience and region. The job outlook for mold setters is projected to grow slightly faster than for die setters, with a 5% increase over the next decade due to greater demand in injection molding within automotive and consumer goods industries. Both roles require technical skill in machine setup and maintenance, but mold setters benefit from broader industry applications, enhancing job security and salary potential.

Die Setter vs Mold Setter Infographic

jobdiv.com

jobdiv.com