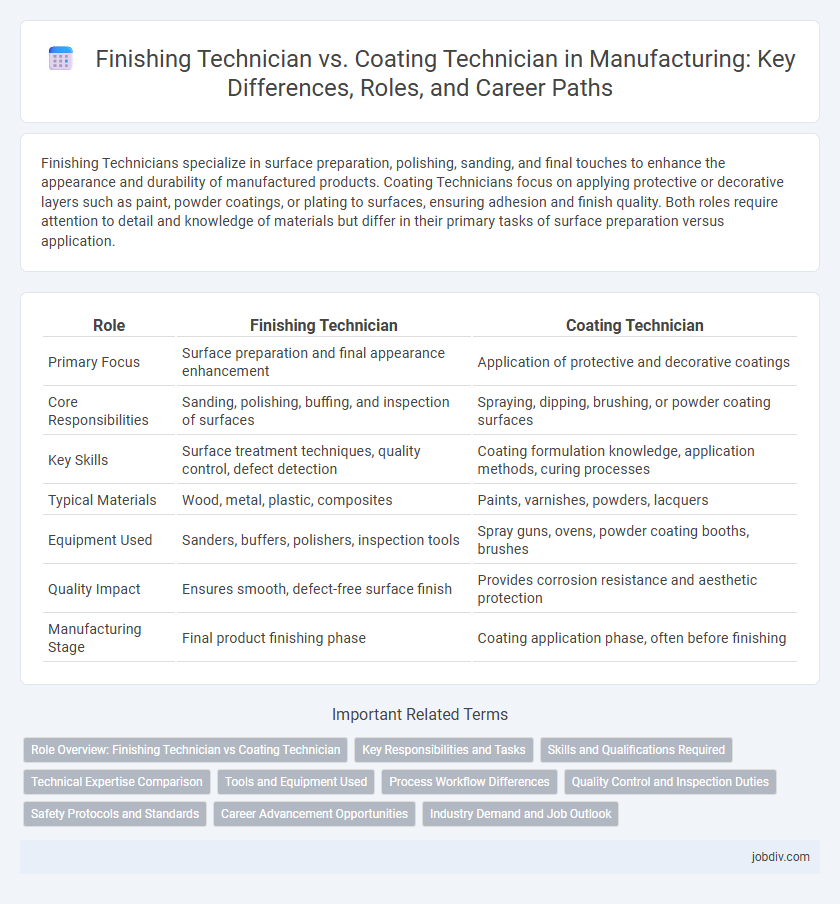

Finishing Technicians specialize in surface preparation, polishing, sanding, and final touches to enhance the appearance and durability of manufactured products. Coating Technicians focus on applying protective or decorative layers such as paint, powder coatings, or plating to surfaces, ensuring adhesion and finish quality. Both roles require attention to detail and knowledge of materials but differ in their primary tasks of surface preparation versus application.

Table of Comparison

| Role | Finishing Technician | Coating Technician |

|---|---|---|

| Primary Focus | Surface preparation and final appearance enhancement | Application of protective and decorative coatings |

| Core Responsibilities | Sanding, polishing, buffing, and inspection of surfaces | Spraying, dipping, brushing, or powder coating surfaces |

| Key Skills | Surface treatment techniques, quality control, defect detection | Coating formulation knowledge, application methods, curing processes |

| Typical Materials | Wood, metal, plastic, composites | Paints, varnishes, powders, lacquers |

| Equipment Used | Sanders, buffers, polishers, inspection tools | Spray guns, ovens, powder coating booths, brushes |

| Quality Impact | Ensures smooth, defect-free surface finish | Provides corrosion resistance and aesthetic protection |

| Manufacturing Stage | Final product finishing phase | Coating application phase, often before finishing |

Role Overview: Finishing Technician vs Coating Technician

A Finishing Technician specializes in applying surface treatments such as polishing, buffing, and deburring to enhance product appearance and durability in manufacturing settings. A Coating Technician focuses on applying protective or decorative coatings, including paints, varnishes, and powder coatings, ensuring uniform coverage and adherence to specifications. Both roles require expertise in quality control and material compatibility but differ primarily in the techniques and end-results of their surface treatment processes.

Key Responsibilities and Tasks

Finishing Technicians focus on surface preparation, sanding, polishing, and applying final finishes to ensure product aesthetics and durability meet quality standards. Coating Technicians specialize in applying protective coatings such as paint, powder, or electroplating to enhance corrosion resistance and product longevity. Both roles require precision in handling materials and equipment, but Finishing Technicians prioritize aesthetic refinement while Coating Technicians emphasize protective layer application.

Skills and Qualifications Required

Finishing Technicians require expertise in surface preparation, sanding, polishing, and applying protective finishes to enhance product durability and aesthetics, often demanding proficiency in hand tools and finishing machinery. Coating Technicians must possess skills in applying various coatings such as paints, powders, and chemical treatments with precision, understanding coating formulations, and operating spray equipment or dipping systems. Both roles necessitate knowledge of safety protocols, quality control measures, and relevant certifications in materials handling and industrial finishing techniques.

Technical Expertise Comparison

Finishing Technicians specialize in surface preparation, polishing, and applying protective or decorative finishes, leveraging expertise in abrasion techniques, chemical treatments, and quality control to ensure product durability and appearance. Coating Technicians focus on applying specialized coatings such as paints, powders, or ceramics using advanced methods like spray guns, electrostatic deposition, and curing processes to enhance corrosion resistance and performance. Both roles require knowledge of material properties and adherence to safety protocols, with Finishing Technicians emphasizing surface refinement and Coating Technicians concentrating on precise application technology.

Tools and Equipment Used

Finishing Technicians primarily utilize sanding machines, grinders, and polishing tools to ensure surfaces are smooth and defect-free, often working with abrasives and buffing pads for detailed surface enhancement. Coating Technicians rely on spray guns, electrostatic applicators, and curing ovens to apply and set protective or decorative coatings, focusing on achieving uniform coverage and adhesion. Both roles require precision instruments such as thickness gauges and inspection tools to maintain quality standards throughout the manufacturing finishing process.

Process Workflow Differences

Finishing Technicians specialize in surface preparation and apply treatments such as sanding, polishing, and buffing to enhance the texture and appearance of manufactured products. Coating Technicians focus on applying protective or decorative layers, using methods like spraying, dipping, or electrostatic coating to ensure durability and corrosion resistance. The workflow for Finishing Technicians involves detailed manual surface refinement before the application of coatings handled by Coating Technicians, who follow precise environmental controls and curing processes.

Quality Control and Inspection Duties

Finishing Technicians primarily focus on surface preparation and polishing, ensuring that parts meet aesthetic and dimensional quality standards through detailed visual inspections and tactile assessments. Coating Technicians specialize in applying protective and decorative coatings, conducting thickness measurements and adhesion tests to verify compliance with specified coating quality parameters. Both roles require stringent quality control protocols to detect defects early, but Finishing Technicians emphasize surface finish integrity while Coating Technicians prioritize coating uniformity and durability.

Safety Protocols and Standards

Finishing Technicians and Coating Technicians both adhere strictly to industry safety protocols such as OSHA regulations and ANSI standards to ensure a hazard-free work environment. Finishing Technicians focus on safe handling and application of materials like solvents and abrasives, using personal protective equipment (PPE) to prevent exposure to chemical fumes and particulates. Coating Technicians prioritize safety in spray booth operations and ventilation systems to minimize inhalation risks and ensure compliance with EPA and NFPA guidelines for fire prevention during coating processes.

Career Advancement Opportunities

Finishing Technicians often advance into supervisory roles or quality control positions by mastering surface preparation and finishing processes critical to product aesthetics and durability. Coating Technicians can progress towards specialized applications, such as advanced paint technology or corrosion protection, frequently moving into process engineering or materials science roles. Both careers benefit from certifications and hands-on experience but diverge based on technical expertise with coatings versus final product finishing, impacting their respective paths in manufacturing leadership and innovation.

Industry Demand and Job Outlook

Finishing Technicians and Coating Technicians both play crucial roles in manufacturing, with industry demand driven by sectors such as automotive, aerospace, and electronics. Job outlook for Finishing Technicians is strong due to their specialization in surface preparation and aesthetic enhancements, which are vital for product durability and appeal. Coating Technicians see increased opportunities as advanced coating technologies and corrosion resistance become priorities in industrial production processes.

Finishing Technician vs Coating Technician Infographic

jobdiv.com

jobdiv.com