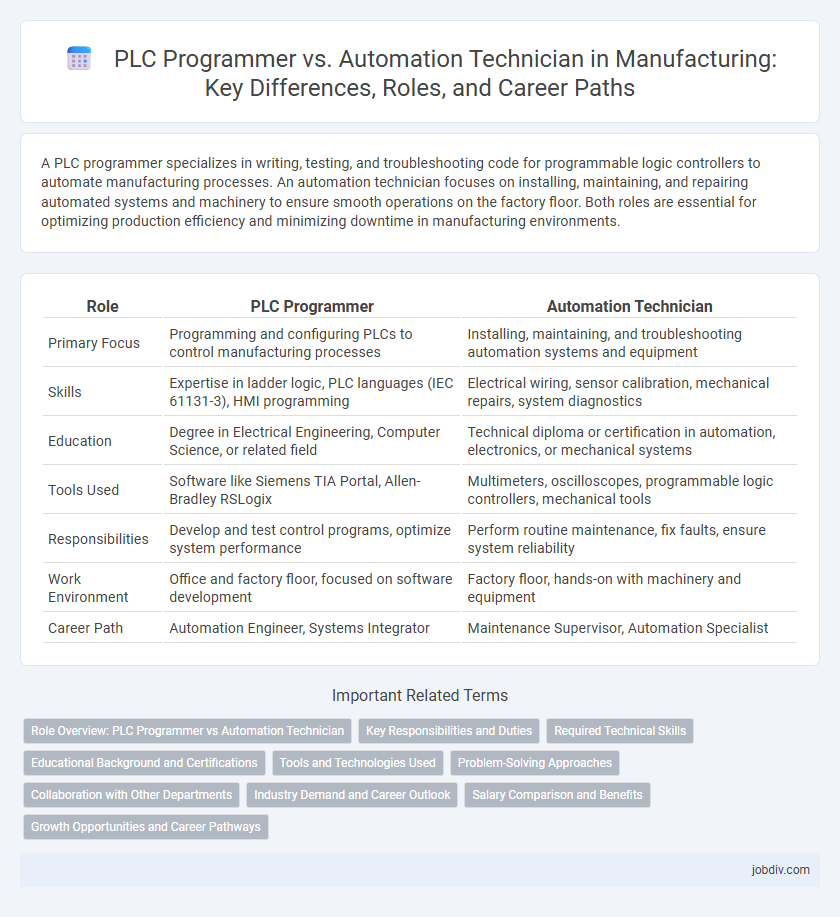

A PLC programmer specializes in writing, testing, and troubleshooting code for programmable logic controllers to automate manufacturing processes. An automation technician focuses on installing, maintaining, and repairing automated systems and machinery to ensure smooth operations on the factory floor. Both roles are essential for optimizing production efficiency and minimizing downtime in manufacturing environments.

Table of Comparison

| Role | PLC Programmer | Automation Technician |

|---|---|---|

| Primary Focus | Programming and configuring PLCs to control manufacturing processes | Installing, maintaining, and troubleshooting automation systems and equipment |

| Skills | Expertise in ladder logic, PLC languages (IEC 61131-3), HMI programming | Electrical wiring, sensor calibration, mechanical repairs, system diagnostics |

| Education | Degree in Electrical Engineering, Computer Science, or related field | Technical diploma or certification in automation, electronics, or mechanical systems |

| Tools Used | Software like Siemens TIA Portal, Allen-Bradley RSLogix | Multimeters, oscilloscopes, programmable logic controllers, mechanical tools |

| Responsibilities | Develop and test control programs, optimize system performance | Perform routine maintenance, fix faults, ensure system reliability |

| Work Environment | Office and factory floor, focused on software development | Factory floor, hands-on with machinery and equipment |

| Career Path | Automation Engineer, Systems Integrator | Maintenance Supervisor, Automation Specialist |

Role Overview: PLC Programmer vs Automation Technician

PLC Programmers specialize in developing, testing, and maintaining programmable logic controllers to automate manufacturing processes, ensuring precise control and system optimization. Automation Technicians focus on installing, troubleshooting, and repairing automated machinery, integrating various hardware components to maintain continuous production flow. Both roles require expertise in industrial control systems but differ in programming depth versus hands-on technical support.

Key Responsibilities and Duties

A PLC Programmer designs, codes, and tests programmable logic controllers to automate manufacturing processes, ensuring system functionality and optimization. An Automation Technician installs, maintains, and troubleshoots automated equipment and control systems to minimize downtime and enhance production efficiency. Both roles require collaboration to improve system performance and support manufacturing automation goals.

Required Technical Skills

PLC programmers require advanced proficiency in programming languages such as ladder logic, structured text, and function block diagrams, alongside strong understanding of industrial communication protocols like Modbus and Profibus. Automation technicians must have hands-on skills in installing, troubleshooting, and maintaining control systems, sensors, and actuators, with expertise in electrical wiring and hardware diagnostics. Both roles demand knowledge of HMI configuration, SCADA systems, and real-time data monitoring to ensure seamless manufacturing automation.

Educational Background and Certifications

PLC Programmers typically hold a degree in electrical engineering, computer science, or industrial automation, emphasizing programming languages such as Ladder Logic and Structured Text. Automation Technicians often possess vocational training or associate degrees focused on mechanical, electrical, and control systems, with certifications like ISA Certified Control Systems Technician (CCST) enhancing their qualifications. Both roles benefit from hands-on experience with industrial control systems, but PLC Programmers require more advanced coding skills, while Automation Technicians emphasize hardware troubleshooting and system maintenance.

Tools and Technologies Used

PLC Programmers primarily utilize programming software such as Siemens TIA Portal, Allen-Bradley RSLogix, and Schneider Electric EcoStruxure Control Expert to develop and troubleshoot control logic. Automation Technicians employ a broader range of tools including multimeters, oscilloscopes, and programmable logic controllers for system installation, diagnostics, and maintenance. Both roles require proficiency with industrial communication protocols like Modbus, Profibus, and Ethernet/IP to optimize manufacturing automation processes.

Problem-Solving Approaches

PLC Programmers focus on developing, coding, and debugging control logic to optimize manufacturing processes, using software-based simulations and systematic troubleshooting to resolve issues. Automation Technicians apply hands-on diagnostics and repair techniques to maintain and fix hardware components, prioritizing practical, real-time problem-solving on the shop floor. Both roles collaborate to enhance system reliability, with PLC Programmers addressing software logic errors and Automation Technicians handling mechanical and electrical faults.

Collaboration with Other Departments

PLC Programmers and Automation Technicians collaborate closely with engineering, maintenance, and production departments to ensure seamless integration of control systems and efficient manufacturing processes. PLC Programmers design and modify control logic, communicating technical requirements to electricians and system operators, while Automation Technicians support installation, troubleshooting, and maintenance, providing real-time feedback to enhance system reliability. Effective cross-departmental collaboration accelerates problem-solving, reduces downtime, and optimizes overall production efficiency.

Industry Demand and Career Outlook

PLC programmers and automation technicians both experience strong industry demand, driven by the rapid growth of smart manufacturing and Industry 4.0 innovations. PLC programmers specialize in designing and maintaining control systems, offering higher salaries due to their advanced programming skills, while automation technicians focus on troubleshooting and maintaining automated machinery. Career outlooks for both roles remain positive, with a projected growth rate of over 9% through 2030, reflecting increased automation across manufacturing sectors.

Salary Comparison and Benefits

PLC Programmers typically command higher salaries, averaging $75,000 to $95,000 annually, due to specialized skills in coding and troubleshooting programmable logic controllers. Automation Technicians earn between $50,000 and $70,000 per year, benefiting from hands-on experience in equipment maintenance and system diagnostics. Both roles offer benefits such as health insurance, retirement plans, and paid training, but PLC Programmers may receive higher bonuses linked to project completions and software development achievements.

Growth Opportunities and Career Pathways

PLC Programmers specialize in designing and coding programmable logic controllers, offering career growth toward senior automation engineer or systems architect roles in manufacturing. Automation Technicians focus on maintaining and troubleshooting automated equipment, enabling advancement to maintenance supervisor or automation manager positions. Both pathways provide robust opportunities in Industry 4.0 environments, with increasing demand for expertise in integrating IoT and advanced robotics.

PLC Programmer vs Automation Technician Infographic

jobdiv.com

jobdiv.com