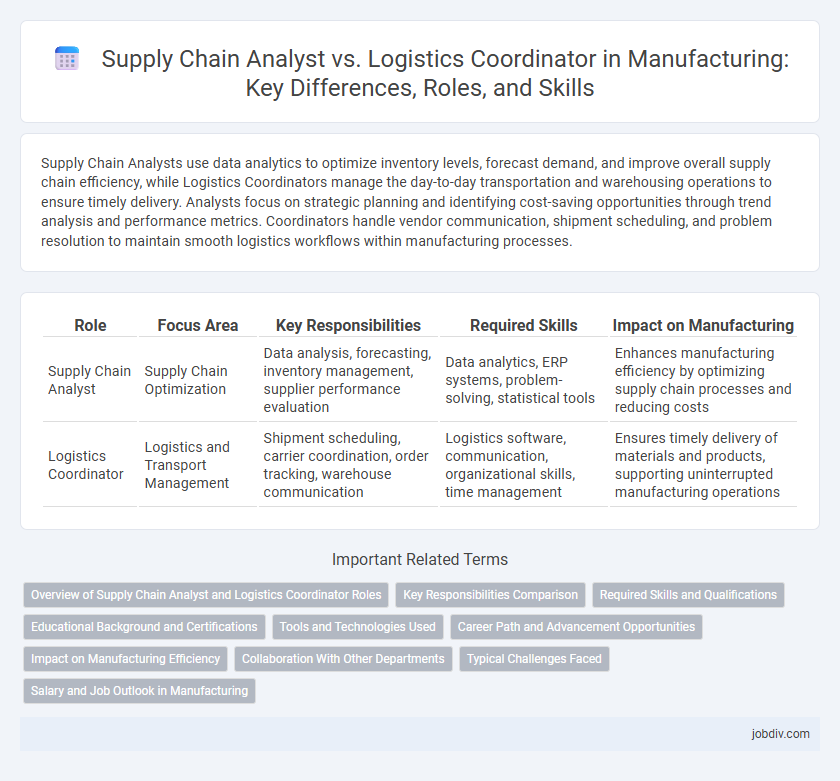

Supply Chain Analysts use data analytics to optimize inventory levels, forecast demand, and improve overall supply chain efficiency, while Logistics Coordinators manage the day-to-day transportation and warehousing operations to ensure timely delivery. Analysts focus on strategic planning and identifying cost-saving opportunities through trend analysis and performance metrics. Coordinators handle vendor communication, shipment scheduling, and problem resolution to maintain smooth logistics workflows within manufacturing processes.

Table of Comparison

| Role | Focus Area | Key Responsibilities | Required Skills | Impact on Manufacturing |

|---|---|---|---|---|

| Supply Chain Analyst | Supply Chain Optimization | Data analysis, forecasting, inventory management, supplier performance evaluation | Data analytics, ERP systems, problem-solving, statistical tools | Enhances manufacturing efficiency by optimizing supply chain processes and reducing costs |

| Logistics Coordinator | Logistics and Transport Management | Shipment scheduling, carrier coordination, order tracking, warehouse communication | Logistics software, communication, organizational skills, time management | Ensures timely delivery of materials and products, supporting uninterrupted manufacturing operations |

Overview of Supply Chain Analyst and Logistics Coordinator Roles

A Supply Chain Analyst specializes in evaluating data related to production, inventory, and transportation to optimize supply chain efficiency and reduce costs. A Logistics Coordinator manages the day-to-day operations of product movement, including scheduling shipments, tracking inventory, and coordinating with suppliers and carriers to ensure timely delivery. Both roles are essential in manufacturing, where the analyst focuses on strategic improvements while the coordinator handles operational execution.

Key Responsibilities Comparison

A Supply Chain Analyst focuses on data analysis, forecasting demand, optimizing inventory levels, and identifying supply chain inefficiencies to enhance overall operational performance. A Logistics Coordinator manages the day-to-day transportation, shipment tracking, warehouse coordination, and communication with carriers to ensure timely delivery of goods. Both roles require collaboration with suppliers and internal teams, but the analyst emphasizes strategy and data-driven decisions, while the coordinator handles execution and logistics operations.

Required Skills and Qualifications

Supply Chain Analysts require strong analytical skills, proficiency in data analysis tools such as SQL and Excel, and knowledge of supply chain management software like SAP or Oracle. Logistics Coordinators need expertise in inventory management, excellent communication skills, and experience with transportation management systems (TMS) to efficiently coordinate shipments. Both roles demand problem-solving abilities and a solid understanding of supply chain processes, but analysts emphasize data-driven decision-making while coordinators focus on operational logistics.

Educational Background and Certifications

Supply Chain Analysts typically hold a bachelor's degree in supply chain management, logistics, or industrial engineering, with many pursuing certifications such as APICS Certified Supply Chain Professional (CSCP) or Certified in Production and Inventory Management (CPIM). Logistics Coordinators often have a diploma or associate degree in logistics, business administration, or transportation management, with certifications like the Certified Logistics Associate (CLA) or Certified Logistics Technician (CLT) enhancing their credentials. Both roles benefit from knowledge in data analysis and inventory management, but Supply Chain Analysts emphasize analytical and strategic planning skills supported by advanced certifications.

Tools and Technologies Used

Supply Chain Analysts employ advanced data analytics tools such as SAP Integrated Business Planning (IBP), Oracle SCM Cloud, and Tableau to forecast demand and optimize inventory management. Logistics Coordinators rely heavily on Transportation Management Systems (TMS) like JDA, Manhattan Associates, and real-time GPS tracking technologies to coordinate shipments and manage carrier relationships. Both roles utilize ERP software, but Supply Chain Analysts emphasize data-driven decision support systems while Logistics Coordinators focus on operational execution platforms.

Career Path and Advancement Opportunities

Supply Chain Analysts specialize in data analysis, forecasting, and process optimization, often advancing into roles such as Supply Chain Manager or Operations Director. Logistics Coordinators focus on coordinating transportation and warehousing activities, with career paths leading to Logistics Manager or Distribution Center Manager positions. Both roles offer growth in manufacturing sectors, but Supply Chain Analysts typically transition into strategic planning and broader operational leadership.

Impact on Manufacturing Efficiency

Supply Chain Analysts use data-driven insights to optimize production schedules and inventory management, directly enhancing manufacturing efficiency by reducing downtime and minimizing waste. Logistics Coordinators ensure timely delivery of raw materials and finished goods, supporting continuous production flow and preventing bottlenecks on the manufacturing floor. Both roles are critical, but Supply Chain Analysts often influence strategic decisions that lead to long-term efficiency improvements in manufacturing operations.

Collaboration With Other Departments

Supply Chain Analysts collaborate closely with procurement, production, and finance teams to optimize inventory levels and forecast demand accurately, ensuring seamless material flow and cost efficiency in manufacturing processes. Logistics Coordinators engage directly with warehouse staff, transportation providers, and customer service departments to coordinate shipments, manage delivery schedules, and resolve transportation issues promptly. Strong interdepartmental communication between these roles enhances operational efficiency, reduces lead times, and supports just-in-time manufacturing strategies.

Typical Challenges Faced

Supply Chain Analysts often face challenges in demand forecasting accuracy due to fluctuating market trends and data inconsistencies, impacting inventory optimization and production planning. Logistics Coordinators encounter difficulties managing transportation delays, route optimization, and coordination among multiple carriers and warehouses, which can disrupt delivery schedules and increase operational costs. Both roles require strong problem-solving skills to address supply disruptions, reduce lead times, and ensure seamless coordination across the manufacturing supply chain.

Salary and Job Outlook in Manufacturing

Supply Chain Analysts in manufacturing typically earn a median salary of $70,000 to $90,000 annually, reflecting their role in data analysis and process optimization, while Logistics Coordinators average around $45,000 to $60,000 due to their focus on managing shipments and inventory. The job outlook for Supply Chain Analysts is projected to grow by 11% through 2030, driven by increasing demand for efficiency and cost reduction in production lines. Logistics Coordinators also face steady demand with a 4% growth rate, as manufacturers require precise coordination of materials and product distribution.

Supply Chain Analyst vs Logistics Coordinator Infographic

jobdiv.com

jobdiv.com