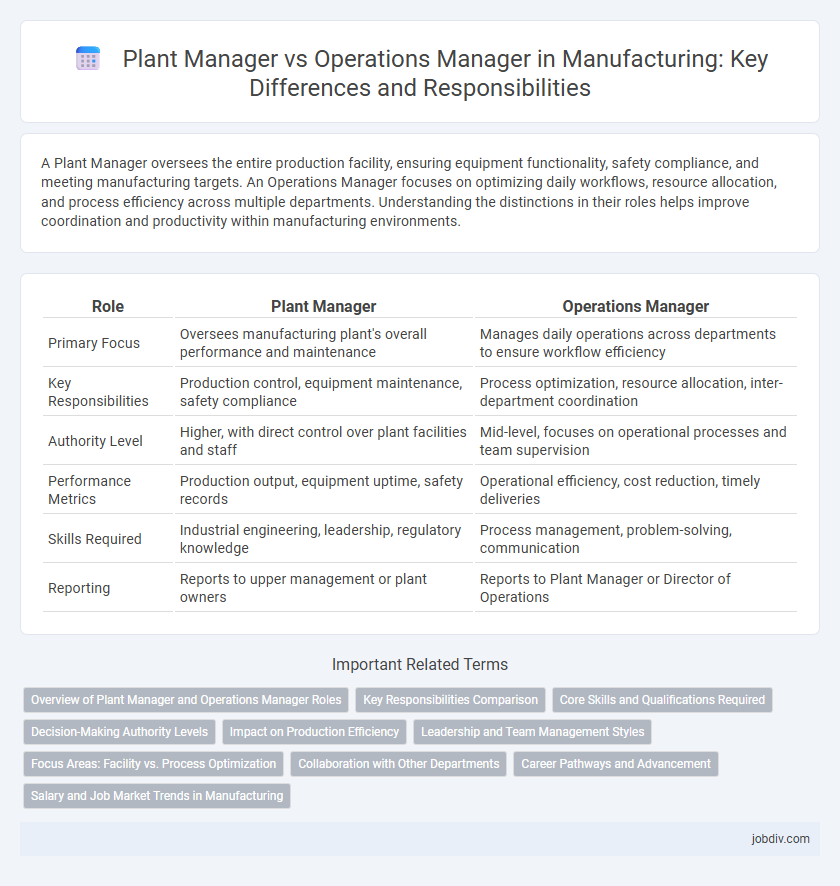

A Plant Manager oversees the entire production facility, ensuring equipment functionality, safety compliance, and meeting manufacturing targets. An Operations Manager focuses on optimizing daily workflows, resource allocation, and process efficiency across multiple departments. Understanding the distinctions in their roles helps improve coordination and productivity within manufacturing environments.

Table of Comparison

| Role | Plant Manager | Operations Manager |

|---|---|---|

| Primary Focus | Oversees manufacturing plant's overall performance and maintenance | Manages daily operations across departments to ensure workflow efficiency |

| Key Responsibilities | Production control, equipment maintenance, safety compliance | Process optimization, resource allocation, inter-department coordination |

| Authority Level | Higher, with direct control over plant facilities and staff | Mid-level, focuses on operational processes and team supervision |

| Performance Metrics | Production output, equipment uptime, safety records | Operational efficiency, cost reduction, timely deliveries |

| Skills Required | Industrial engineering, leadership, regulatory knowledge | Process management, problem-solving, communication |

| Reporting | Reports to upper management or plant owners | Reports to Plant Manager or Director of Operations |

Overview of Plant Manager and Operations Manager Roles

Plant Managers oversee the entire manufacturing facility, ensuring production targets, safety standards, and quality control are met while managing resources and staff. Operations Managers focus on streamlining processes, optimizing workflow, and coordinating between departments to enhance efficiency and reduce costs across production lines. Both roles are critical for maintaining smooth manufacturing operations but differ in scope, with Plant Managers having broader facility-wide responsibilities and Operations Managers concentrating on process optimization.

Key Responsibilities Comparison

Plant Managers oversee the entire manufacturing facility, ensuring production targets, quality standards, and equipment maintenance are met efficiently. Operations Managers focus on optimizing workflow, managing supply chain logistics, and streamlining processes to increase overall productivity. Both roles require coordination of teams and adherence to safety regulations, but Plant Managers have broader responsibility for facility management while Operations Managers concentrate on operational efficiency.

Core Skills and Qualifications Required

Plant Managers require strong expertise in production processes, equipment maintenance, and quality control, paired with leadership skills to manage large teams and ensure safety compliance. Operations Managers need proficiency in workflow optimization, supply chain coordination, and budget management, emphasizing strategic planning and cross-departmental communication. Both roles demand a solid foundation in project management, problem-solving, and familiarity with manufacturing software systems.

Decision-Making Authority Levels

Plant Managers hold comprehensive decision-making authority over production processes, resource allocation, and facility management to ensure operational efficiency and safety compliance. Operations Managers focus on tactical decisions regarding daily workflow, personnel scheduling, and process optimization within specific departments or units. The Plant Manager's strategic oversight typically encompasses broader organizational goals, while the Operations Manager implements policies to meet those objectives on the ground level.

Impact on Production Efficiency

Plant managers directly influence production efficiency by overseeing the entire manufacturing process, ensuring machinery uptime, and managing workforce productivity. Operations managers optimize resource allocation, streamline workflows, and coordinate supply chain activities to maximize output and minimize waste. Both roles are critical in reducing production bottlenecks and enhancing overall manufacturing performance.

Leadership and Team Management Styles

Plant Managers emphasize strategic leadership by aligning production goals with overall business objectives, fostering a culture of continuous improvement, and maintaining strong accountability for safety and quality standards. Operations Managers focus on tactical leadership, overseeing daily workflows, optimizing resource allocation, and directly managing cross-functional teams to ensure efficient process execution. Both roles require adaptive communication skills tailored to motivate diverse teams and drive operational excellence within manufacturing environments.

Focus Areas: Facility vs. Process Optimization

Plant Managers concentrate on facility management, ensuring machinery maintenance, safety compliance, and overall infrastructure efficiency. Operations Managers prioritize process optimization by streamlining workflows, improving production methods, and enhancing supply chain coordination. Both roles drive manufacturing performance through complementary focus on physical assets and operational processes.

Collaboration with Other Departments

Plant Managers foster cross-departmental collaboration by coordinating closely with maintenance, quality control, and supply chain teams to ensure seamless production flow. Operations Managers facilitate communication between production, logistics, and procurement departments to optimize resource allocation and operational efficiency. Both roles leverage interdepartmental teamwork to drive manufacturing productivity and resolve operational bottlenecks.

Career Pathways and Advancement

Plant Managers typically advance from roles such as Operations Manager, gaining expertise in production processes, quality control, and team leadership, positioning themselves for executive responsibilities. Operations Managers often begin in supervisory or technical positions, developing skills in workflow optimization, resource allocation, and staff management, which create opportunities for promotion to Plant Manager or higher operational roles. Both career pathways emphasize continuous development in strategic planning, process improvement, and cross-functional coordination to achieve leadership advancement in manufacturing organizations.

Salary and Job Market Trends in Manufacturing

Plant Managers in manufacturing typically earn higher salaries, averaging $90,000 to $130,000 annually, due to their responsibility for overseeing entire facility operations and strategic planning. Operations Managers, with a salary range of $70,000 to $110,000, focus more on daily workflow efficiency and resource management, reflecting differing scopes of authority and expertise. Job market trends indicate strong demand for both roles, with Plant Manager positions growing by 5% annually as manufacturing plants expand, while Operations Manager roles increase by 4%, driven by continuous process optimizations and supply chain improvements.

Plant Manager vs Operations Manager Infographic

jobdiv.com

jobdiv.com