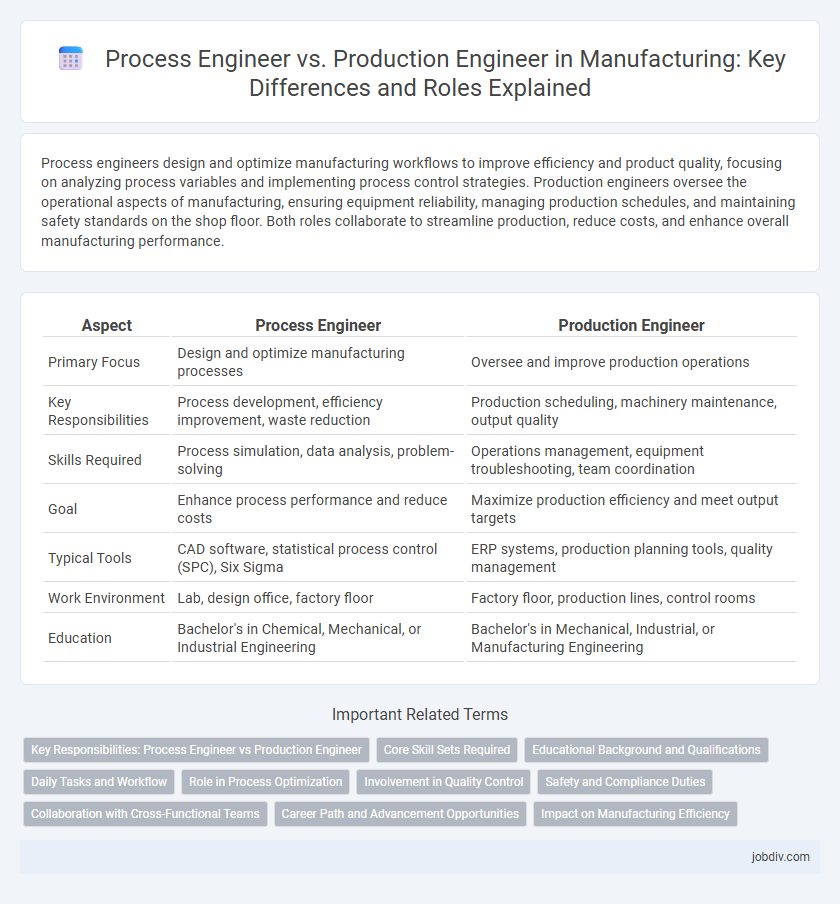

Process engineers design and optimize manufacturing workflows to improve efficiency and product quality, focusing on analyzing process variables and implementing process control strategies. Production engineers oversee the operational aspects of manufacturing, ensuring equipment reliability, managing production schedules, and maintaining safety standards on the shop floor. Both roles collaborate to streamline production, reduce costs, and enhance overall manufacturing performance.

Table of Comparison

| Aspect | Process Engineer | Production Engineer |

|---|---|---|

| Primary Focus | Design and optimize manufacturing processes | Oversee and improve production operations |

| Key Responsibilities | Process development, efficiency improvement, waste reduction | Production scheduling, machinery maintenance, output quality |

| Skills Required | Process simulation, data analysis, problem-solving | Operations management, equipment troubleshooting, team coordination |

| Goal | Enhance process performance and reduce costs | Maximize production efficiency and meet output targets |

| Typical Tools | CAD software, statistical process control (SPC), Six Sigma | ERP systems, production planning tools, quality management |

| Work Environment | Lab, design office, factory floor | Factory floor, production lines, control rooms |

| Education | Bachelor's in Chemical, Mechanical, or Industrial Engineering | Bachelor's in Mechanical, Industrial, or Manufacturing Engineering |

Key Responsibilities: Process Engineer vs Production Engineer

Process Engineers focus on designing, implementing, and optimizing manufacturing processes to improve efficiency, quality, and safety while reducing costs and waste. Production Engineers oversee the daily operations of the production floor, ensuring machinery runs smoothly, managing workflow, and meeting production targets and deadlines. Both roles collaborate closely, but Process Engineers emphasize process innovation and scalability, whereas Production Engineers concentrate on operational execution and resource management.

Core Skill Sets Required

Process Engineers require expertise in process design, optimization, and control, with strong skills in data analysis, chemical engineering principles, and process simulation software. Production Engineers focus on manufacturing systems, equipment maintenance, workflow management, and quality control, emphasizing skills in operations management, lean manufacturing, and troubleshooting. Both roles demand problem-solving capabilities, but Process Engineers prioritize process efficiency while Production Engineers concentrate on production output and resource utilization.

Educational Background and Qualifications

Process Engineers typically hold a degree in chemical, industrial, or manufacturing engineering, emphasizing knowledge in process design, optimization, and control systems. Production Engineers often have educational backgrounds in mechanical, industrial, or manufacturing engineering, focusing on production planning, workflow management, and quality control. Both roles require strong analytical skills and familiarity with CAD software, lean manufacturing principles, and Six Sigma certifications to improve manufacturing efficiency and product quality.

Daily Tasks and Workflow

Process engineers design, optimize, and analyze manufacturing workflows to improve efficiency, quality, and safety, often using data-driven methods and simulation tools. Production engineers focus on overseeing daily operations on the shop floor, managing equipment maintenance, and coordinating workforce activities to meet production targets. Both roles require collaboration but differ in scope; process engineers emphasize system improvements, while production engineers prioritize execution and troubleshooting within the manufacturing cycle.

Role in Process Optimization

Process Engineers design and refine manufacturing workflows to enhance efficiency, reduce waste, and ensure product quality through data-driven analysis and continuous improvement techniques. Production Engineers concentrate on implementing and maintaining equipment and production lines, optimizing operational performance and minimizing downtime to meet production targets. Both roles collaborate closely to align process optimization initiatives with production capabilities and business objectives.

Involvement in Quality Control

Process Engineers focus on designing and optimizing manufacturing processes to improve product quality and efficiency, ensuring adherence to quality standards at each production stage. Production Engineers oversee the day-to-day manufacturing operations, implementing quality control measures and troubleshooting issues to maintain consistent output. Both roles collaborate closely with quality assurance teams to minimize defects and enhance overall product reliability.

Safety and Compliance Duties

Process Engineers ensure manufacturing processes comply with safety regulations by analyzing risks, implementing control measures, and maintaining process documentation. Production Engineers focus on workplace safety by optimizing production activities, enforcing safety protocols, and conducting regular compliance audits. Both roles prioritize adherence to OSHA standards and industry-specific safety guidelines to minimize hazards and ensure regulatory compliance.

Collaboration with Cross-Functional Teams

Process Engineers optimize manufacturing workflows by analyzing systems and implementing efficiency improvements, collaborating closely with quality, maintenance, and R&D teams to ensure seamless production. Production Engineers focus on overseeing day-to-day operations, working hand-in-hand with supply chain, logistics, and plant management to meet output targets and resolve operational issues. Effective collaboration between these roles and cross-functional teams drives continuous improvement and enhances overall manufacturing performance.

Career Path and Advancement Opportunities

Process Engineers focus on optimizing manufacturing workflows and improving efficiency through process design and innovation, often progressing into roles like Manufacturing Manager or Quality Assurance Director. Production Engineers concentrate on overseeing day-to-day production, ensuring equipment functionality and meeting output targets, with career advancements leading to Production Supervisors or Operations Managers. Both career paths offer opportunities in continuous improvement and leadership, but Process Engineers typically advance by developing technical expertise, while Production Engineers move forward through operational management.

Impact on Manufacturing Efficiency

Process Engineers optimize manufacturing workflows by designing and refining production processes, leading to reduced cycle times and minimized waste. Production Engineers ensure equipment reliability and manage daily operations, directly influencing machine uptime and product quality. Their collaboration significantly enhances overall manufacturing efficiency through streamlined processes and consistent output.

Process Engineer vs Production Engineer Infographic

jobdiv.com

jobdiv.com