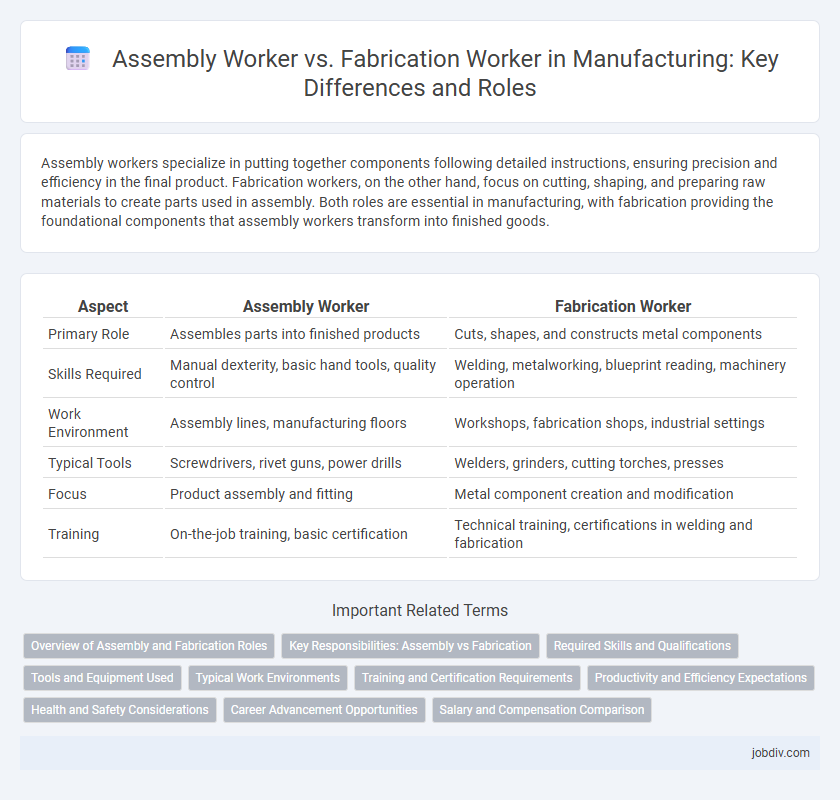

Assembly workers specialize in putting together components following detailed instructions, ensuring precision and efficiency in the final product. Fabrication workers, on the other hand, focus on cutting, shaping, and preparing raw materials to create parts used in assembly. Both roles are essential in manufacturing, with fabrication providing the foundational components that assembly workers transform into finished goods.

Table of Comparison

| Aspect | Assembly Worker | Fabrication Worker |

|---|---|---|

| Primary Role | Assembles parts into finished products | Cuts, shapes, and constructs metal components |

| Skills Required | Manual dexterity, basic hand tools, quality control | Welding, metalworking, blueprint reading, machinery operation |

| Work Environment | Assembly lines, manufacturing floors | Workshops, fabrication shops, industrial settings |

| Typical Tools | Screwdrivers, rivet guns, power drills | Welders, grinders, cutting torches, presses |

| Focus | Product assembly and fitting | Metal component creation and modification |

| Training | On-the-job training, basic certification | Technical training, certifications in welding and fabrication |

Overview of Assembly and Fabrication Roles

Assembly workers specialize in putting together components and parts to create finished products, often following precise blueprints and using tools like screwdrivers and riveters. Fabrication workers focus on shaping and cutting raw materials such as metal or plastic through processes like welding, machining, and laser cutting to prepare parts for assembly. Both roles require technical skills and attention to detail but differ in the stage of production they contribute to within manufacturing workflows.

Key Responsibilities: Assembly vs Fabrication

Assembly workers focus on putting together components and parts to create finished products, often following detailed blueprints and using hand tools or machinery. Fabrication workers specialize in cutting, shaping, and welding raw materials like metal or plastic to produce parts required for assemblies. Both roles demand precision and technical skills but differ in scope, with fabrication emphasizing material manipulation and assembly concentrating on final product construction.

Required Skills and Qualifications

Assembly workers require precision in interpreting blueprints, manual dexterity, and experience with hand tools and automated machinery to ensure accurate product assembly. Fabrication workers must possess skills in welding, metal cutting, and proficiency with heavy machinery, alongside certifications such as OSHA safety compliance and a strong understanding of materials science. Both roles prioritize physical stamina and attention to detail, but fabrication demands advanced technical training in metallurgy and structural assembly.

Tools and Equipment Used

Assembly workers utilize hand tools such as screwdrivers, wrenches, and power drills to join components precisely according to specifications, often relying on jigs and fixtures for alignment. Fabrication workers operate heavy machinery like CNC machines, welding equipment, and metal cutters to shape and form raw materials into custom parts. Both roles require specialized safety gear, but fabrication involves more robust equipment for material manipulation, while assembly emphasizes precision tools for component integration.

Typical Work Environments

Assembly workers typically perform tasks on production lines within clean, climate-controlled factory floors designed for efficiency and safety. Fabrication workers often operate in more varied environments, including heavy industrial shops where metal cutting, welding, and large machinery handling take place, requiring additional safety measures and protective gear. Both roles demand adherence to strict safety protocols but differ significantly in noise levels, physical demands, and environmental exposures.

Training and Certification Requirements

Assembly workers typically require on-the-job training and basic certification in workplace safety, with proficiency in reading technical manuals and operating hand tools being essential. Fabrication workers often need more specialized training, including certifications in welding, blueprint reading, and machine operation, reflecting the complexity of metal cutting and shaping tasks. Both roles benefit from continuous education in lean manufacturing and quality control to enhance production efficiency and compliance.

Productivity and Efficiency Expectations

Assembly workers specialize in efficiently putting together pre-manufactured parts, optimizing line speed to meet strict production targets with minimal error rates. Fabrication workers focus on shaping, cutting, and forming raw materials, where precision and reducing material waste directly impact overall productivity. Both roles demand high accuracy and consistent output, but assembly workers often achieve faster cycle times due to standardized component integration.

Health and Safety Considerations

Assembly workers face repetitive motion risks and require ergonomic workstations to prevent musculoskeletal disorders, while fabrication workers are exposed to hazards such as sharp tools, welding fumes, and heavy machinery needing strict use of personal protective equipment (PPE). Both roles must comply with Occupational Safety and Health Administration (OSHA) standards, including proper training in hazard communication and emergency response procedures. Implementing regular safety audits and ensuring machinery guards and ventilation systems are in place minimizes workplace injuries and exposure to harmful substances.

Career Advancement Opportunities

Assembly workers often have clear pathways to supervisory roles or quality control positions due to their hands-on experience with product assembly processes. Fabrication workers can advance by gaining specialized skills in welding, machining, or CNC programming, leading to roles such as fabrication supervisor or manufacturing technician. Both positions benefit from additional certifications and continuous training, enhancing prospects for higher salaries and leadership roles in the manufacturing sector.

Salary and Compensation Comparison

Assembly workers in manufacturing typically earn an average hourly wage of $15 to $20, with annual salaries ranging from $31,000 to $42,000, while fabrication workers often command higher pay due to specialized skills, averaging $18 to $25 per hour or $37,000 to $52,000 annually. Compensation packages for fabrication workers frequently include bonuses and overtime opportunities, reflecting the technical expertise required for cutting, welding, and shaping metal components. Salary differences also stem from the complexity of tasks, with fabrication roles demanding certifications and experience that contribute to increased earnings compared to general assembly positions.

Assembly Worker vs Fabrication Worker Infographic

jobdiv.com

jobdiv.com