Inventory controllers manage stock levels, track inventory accuracy, and oversee order fulfillment to ensure consistent production flow. Materials handlers are responsible for the physical movement, loading, and unloading of raw materials and finished goods within the facility. Both roles are essential for efficient manufacturing operations, with inventory controllers focusing on data management and materials handlers on logistics execution.

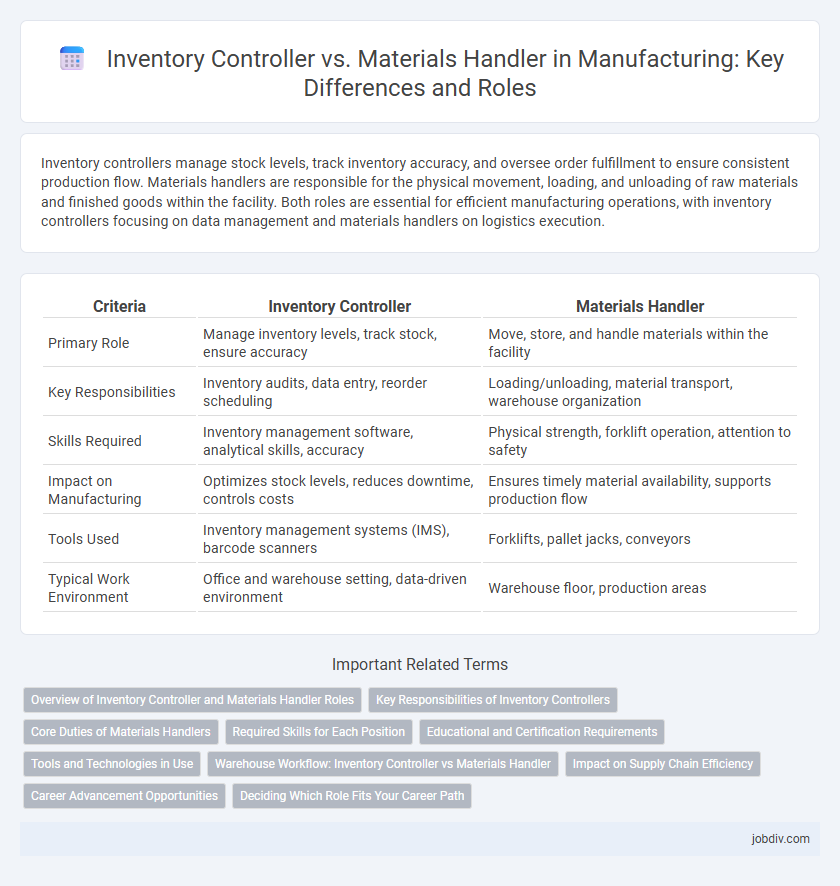

Table of Comparison

| Criteria | Inventory Controller | Materials Handler |

|---|---|---|

| Primary Role | Manage inventory levels, track stock, ensure accuracy | Move, store, and handle materials within the facility |

| Key Responsibilities | Inventory audits, data entry, reorder scheduling | Loading/unloading, material transport, warehouse organization |

| Skills Required | Inventory management software, analytical skills, accuracy | Physical strength, forklift operation, attention to safety |

| Impact on Manufacturing | Optimizes stock levels, reduces downtime, controls costs | Ensures timely material availability, supports production flow |

| Tools Used | Inventory management systems (IMS), barcode scanners | Forklifts, pallet jacks, conveyors |

| Typical Work Environment | Office and warehouse setting, data-driven environment | Warehouse floor, production areas |

Overview of Inventory Controller and Materials Handler Roles

Inventory Controllers oversee stock levels, coordinate inventory audits, and maintain accurate records to ensure efficient supply chain operations. Materials Handlers manage the physical movement, storage, and distribution of raw materials and finished goods within the manufacturing facility. Both roles are critical for optimizing production flow, reducing downtime, and minimizing inventory costs.

Key Responsibilities of Inventory Controllers

Inventory Controllers oversee stock levels, manage inventory accuracy, and coordinate with purchasing to ensure materials availability in manufacturing processes. They implement inventory control systems, conduct regular audits, and analyze stock data to prevent shortages or overstock situations. Their role directly impacts production efficiency and cost management by maintaining optimal inventory turnover and minimizing waste.

Core Duties of Materials Handlers

Materials Handlers in manufacturing are responsible for receiving, storing, and distributing raw materials and finished products to ensure seamless production flow. Core duties include verifying inventory accuracy, organizing stock locations, and operating material-handling equipment such as forklifts. Their role contrasts with Inventory Controllers who primarily focus on tracking stock levels, maintaining inventory records, and coordinating reorder processes.

Required Skills for Each Position

Inventory Controllers require strong analytical skills, proficiency in inventory management software, and attention to detail to accurately track stock levels and forecast demand. Materials Handlers need physical stamina, basic operation knowledge of forklifts or pallet jacks, and strong organizational abilities to efficiently move and manage raw materials and finished goods. Both roles demand effective communication skills and a thorough understanding of safety regulations in manufacturing environments.

Educational and Certification Requirements

Inventory Controllers typically require a diploma or degree in supply chain management, logistics, or business administration, with certifications such as Certified in Production and Inventory Management (CPIM) enhancing their qualifications. Materials Handlers often need a high school diploma or equivalent, with on-the-job training being common, while certifications like OSHA forklift operator or hazardous materials handling improve job prospects. Both roles benefit from familiarity with inventory management software, but Inventory Controllers demand higher educational credentials to manage planning and documentation tasks effectively.

Tools and Technologies in Use

Inventory Controllers utilize advanced inventory management software such as SAP and Oracle to track stock levels, forecast demand, and optimize reorder points. Materials Handlers rely on barcode scanners, RFID technology, and automated conveyor systems to efficiently move and track materials within the manufacturing floor. Both roles integrate IoT devices and warehouse management systems (WMS) to enhance accuracy and streamline supply chain operations.

Warehouse Workflow: Inventory Controller vs Materials Handler

Inventory Controllers oversee accurate stock levels, manage reorder points, and maintain real-time inventory data to optimize warehouse workflow efficiency. Materials Handlers execute physical tasks such as receiving, storing, and moving materials within the warehouse to ensure smooth operational flow and timely order fulfillment. Coordination between Inventory Controllers and Materials Handlers is crucial for minimizing stock discrepancies and streamlining warehouse productivity.

Impact on Supply Chain Efficiency

Inventory controllers optimize supply chain efficiency by accurately tracking stock levels, forecasting demand, and coordinating replenishment to prevent stockouts and overstock situations. Materials handlers directly influence operational flow by ensuring timely movement and proper storage of raw materials and finished goods, minimizing delays on the production floor. Together, their roles synchronize inventory management and physical material handling, enhancing overall supply chain responsiveness and reducing lead times.

Career Advancement Opportunities

Inventory Controllers typically have greater career advancement opportunities due to their role in managing stock levels, analyzing data, and coordinating supply chain processes, which are critical for operational efficiency. Materials Handlers primarily focus on the physical movement and organization of materials within the manufacturing facility, offering more entry-level growth paths such as supervisory roles in warehouse operations. Professionals aiming for higher management positions often benefit from the strategic and analytical skills developed in inventory control over the hands-on experience gained as a materials handler.

Deciding Which Role Fits Your Career Path

Inventory Controllers manage stock levels, track inventory accuracy, and optimize supply chain efficiency using software tools like ERP systems, making them ideal for those interested in data analysis and strategic planning. Materials Handlers focus on the physical movement, storage, and organization of raw materials and finished goods within manufacturing facilities, suited for individuals preferring hands-on, operational roles. Choosing between these careers depends on your strengths and career goals: analytical skills and process optimization versus physical stamina and logistical coordination.

Inventory Controller vs Materials Handler Infographic

jobdiv.com

jobdiv.com