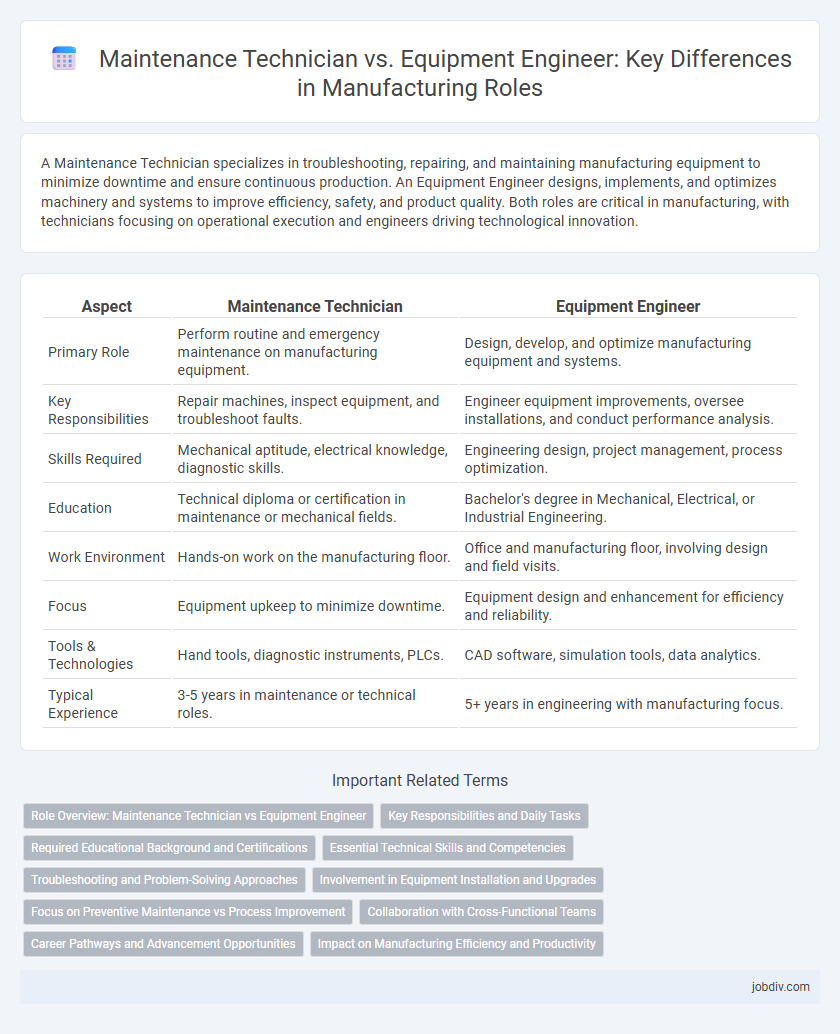

A Maintenance Technician specializes in troubleshooting, repairing, and maintaining manufacturing equipment to minimize downtime and ensure continuous production. An Equipment Engineer designs, implements, and optimizes machinery and systems to improve efficiency, safety, and product quality. Both roles are critical in manufacturing, with technicians focusing on operational execution and engineers driving technological innovation.

Table of Comparison

| Aspect | Maintenance Technician | Equipment Engineer |

|---|---|---|

| Primary Role | Perform routine and emergency maintenance on manufacturing equipment. | Design, develop, and optimize manufacturing equipment and systems. |

| Key Responsibilities | Repair machines, inspect equipment, and troubleshoot faults. | Engineer equipment improvements, oversee installations, and conduct performance analysis. |

| Skills Required | Mechanical aptitude, electrical knowledge, diagnostic skills. | Engineering design, project management, process optimization. |

| Education | Technical diploma or certification in maintenance or mechanical fields. | Bachelor's degree in Mechanical, Electrical, or Industrial Engineering. |

| Work Environment | Hands-on work on the manufacturing floor. | Office and manufacturing floor, involving design and field visits. |

| Focus | Equipment upkeep to minimize downtime. | Equipment design and enhancement for efficiency and reliability. |

| Tools & Technologies | Hand tools, diagnostic instruments, PLCs. | CAD software, simulation tools, data analytics. |

| Typical Experience | 3-5 years in maintenance or technical roles. | 5+ years in engineering with manufacturing focus. |

Role Overview: Maintenance Technician vs Equipment Engineer

Maintenance Technicians focus on routine inspections, troubleshooting, and repairing manufacturing equipment to ensure operational efficiency and minimize downtime. Equipment Engineers design, develop, and improve machinery, integrating advanced technologies to optimize production processes and enhance equipment performance. Both roles are critical for maintaining seamless manufacturing operations but differ in their scope of responsibility and technical involvement.

Key Responsibilities and Daily Tasks

Maintenance Technicians specialize in routine inspections, troubleshooting, and repairing machinery to ensure continuous production flow, focusing on immediate operational issues and preventive maintenance. Equipment Engineers design, analyze, and optimize manufacturing equipment, implementing upgrades and modifications to enhance performance and reliability while collaborating on project development. Both roles are essential for minimizing downtime and improving equipment efficiency, with Technicians handling hands-on repairs and Engineers addressing long-term technical solutions.

Required Educational Background and Certifications

Maintenance Technicians typically require a high school diploma or technical certification, with specialized training in mechanical or electrical systems often preferred. Equipment Engineers generally hold a bachelor's degree in engineering disciplines such as mechanical, electrical, or industrial engineering and frequently obtain certifications like Professional Engineer (PE) or Six Sigma. Certification in safety standards and equipment-specific credentials enhance expertise and job performance for both roles.

Essential Technical Skills and Competencies

Maintenance Technicians require hands-on skills in troubleshooting, preventive maintenance, and repair of machinery, with proficiency in hydraulic, pneumatic, and electrical systems to ensure equipment reliability. Equipment Engineers possess advanced competencies in equipment design, process optimization, and root cause analysis, leveraging CAD software and data analytics to improve asset performance and lifecycle management. Both roles demand strong mechanical aptitude and knowledge of safety protocols, but Equipment Engineers focus more on strategic enhancement, while Maintenance Technicians emphasize operational support.

Troubleshooting and Problem-Solving Approaches

Maintenance Technicians specialize in hands-on troubleshooting by performing routine inspections and immediate repairs to minimize equipment downtime, leveraging their practical knowledge of machine operations. Equipment Engineers apply advanced problem-solving techniques using data analysis, root cause identification, and design modifications to improve equipment reliability and prevent recurring failures. Both roles collaborate closely, with technicians addressing urgent operational issues and engineers focusing on long-term equipment optimization through systematic analysis.

Involvement in Equipment Installation and Upgrades

Maintenance Technicians primarily focus on the hands-on tasks of equipment installation and routine upgrades, ensuring operational functionality and minimizing downtime. Equipment Engineers lead the design and planning phases of installations and upgrades, optimizing performance specifications and integrating advanced technologies. Both roles are essential, with engineers driving strategic improvements and technicians executing practical implementation in manufacturing environments.

Focus on Preventive Maintenance vs Process Improvement

Maintenance Technicians prioritize preventive maintenance by conducting routine inspections, servicing machinery, and troubleshooting equipment to minimize downtime and extend asset life. Equipment Engineers focus on process improvement by analyzing system inefficiencies, implementing design enhancements, and optimizing equipment performance to boost production quality and reduce operational costs. Both roles are essential for maximizing manufacturing efficiency and reliability through complementary strategies.

Collaboration with Cross-Functional Teams

Maintenance Technicians and Equipment Engineers collaborate closely with cross-functional teams including production, quality assurance, and safety to ensure optimal machine performance and minimal downtime. Their combined expertise allows for proactive identification and resolution of equipment issues, streamlining manufacturing processes and boosting operational efficiency. Effective communication between these roles supports continuous improvement initiatives and adherence to industry standards such as TPM and ISO 9001.

Career Pathways and Advancement Opportunities

Maintenance Technicians in manufacturing typically begin with hands-on roles focused on routine repairs and preventive maintenance, advancing to senior technician or supervisory positions through skill mastery and certifications. Equipment Engineers follow a more analytical career path, often requiring an engineering degree and progressing to roles in equipment design, process optimization, and project management. Both career paths offer advancement opportunities, but Equipment Engineers generally have broader prospects in strategic decision-making and innovation within manufacturing operations.

Impact on Manufacturing Efficiency and Productivity

Maintenance Technicians ensure continuous operation by quickly diagnosing and repairing equipment malfunctions, which minimizes downtime and maintains production flow. Equipment Engineers design, upgrade, and optimize machinery systems, improving reliability and enabling higher throughput with reduced energy consumption. Both roles are critical for manufacturing efficiency, with Technicians addressing immediate operational issues and Engineers driving long-term productivity improvements through technical innovation.

Maintenance Technician vs Equipment Engineer Infographic

jobdiv.com

jobdiv.com