Machine operators primarily handle the setup and monitoring of equipment to ensure production runs smoothly, while machinists are skilled tradespeople who create precision metal parts using various machine tools. Operators follow standardized procedures and maintain machinery efficiency, whereas machinists interpret blueprints and make adjustments to achieve exact specifications. Understanding the distinction between these roles is essential for optimizing manufacturing workflow and maintaining product quality.

Table of Comparison

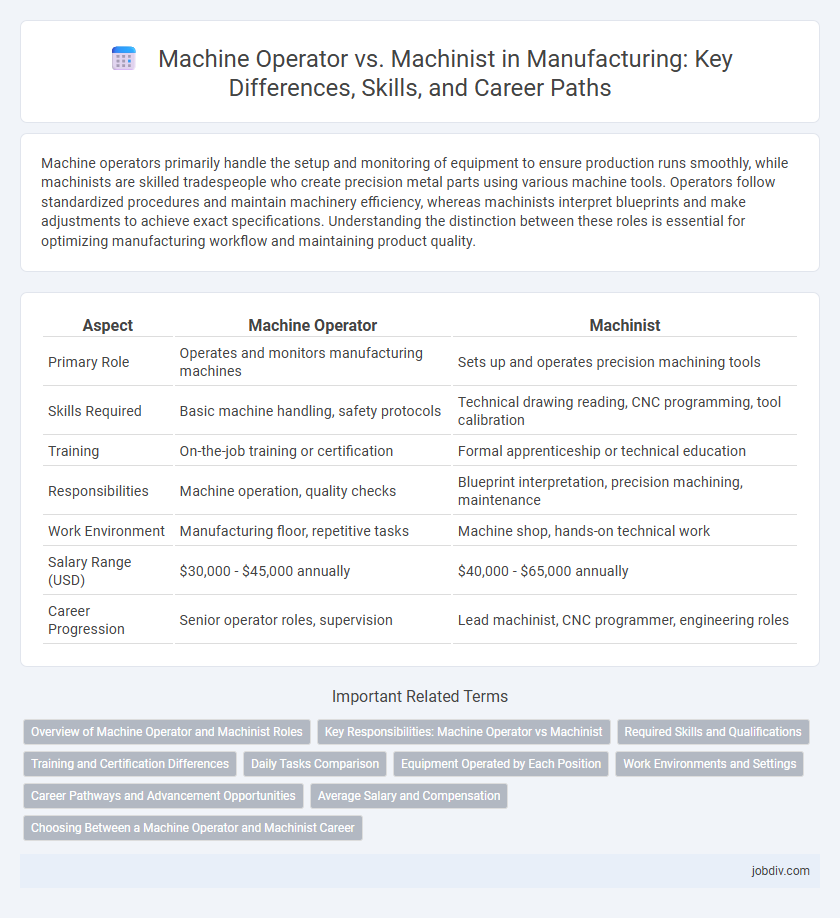

| Aspect | Machine Operator | Machinist |

|---|---|---|

| Primary Role | Operates and monitors manufacturing machines | Sets up and operates precision machining tools |

| Skills Required | Basic machine handling, safety protocols | Technical drawing reading, CNC programming, tool calibration |

| Training | On-the-job training or certification | Formal apprenticeship or technical education |

| Responsibilities | Machine operation, quality checks | Blueprint interpretation, precision machining, maintenance |

| Work Environment | Manufacturing floor, repetitive tasks | Machine shop, hands-on technical work |

| Salary Range (USD) | $30,000 - $45,000 annually | $40,000 - $65,000 annually |

| Career Progression | Senior operator roles, supervision | Lead machinist, CNC programmer, engineering roles |

Overview of Machine Operator and Machinist Roles

Machine operators handle the setup, control, and maintenance of machinery used in manufacturing processes, ensuring efficient production and adherence to safety standards. Machinists specialize in operating precision tools and CNC machines to create detailed components, often requiring advanced technical skills and blueprint interpretation. Both roles are crucial in manufacturing, with operators focusing on machine functionality and production flow, while machinists emphasize precision machining and part fabrication.

Key Responsibilities: Machine Operator vs Machinist

Machine Operators primarily focus on setting up and controlling machinery to produce parts according to specifications, performing routine maintenance, and monitoring equipment performance for safety and efficiency. Machinists specialize in operating precision machine tools, interpreting blueprints, and fabricating or modifying metal parts with high accuracy using milling machines, lathes, or CNC equipment. Both roles require technical expertise, but machinists emphasize detailed craftsmanship and adjustments, while machine operators concentrate on managing production processes.

Required Skills and Qualifications

Machine operators require basic mechanical skills, the ability to follow detailed instructions, and proficiency in operating computerized control panels for standardized production tasks. Machinists need advanced technical knowledge, including blueprint reading, precision measuring, and programming CNC machines, often necessitating formal training or apprenticeships. Both roles demand strong attention to detail and adherence to safety protocols, but machinists typically possess a higher level of expertise in metalworking and tooling adjustments.

Training and Certification Differences

Machine operators typically require basic training focused on operating specific equipment safely and efficiently, often completed through on-the-job programs or vocational courses. Machinists undergo more extensive training involving precision measurement, blueprint reading, and programming CNC machines, usually acquired through technical schools or apprenticeships. Certification for machinists often includes recognized credentials like the National Institute for Metalworking Skills (NIMS), whereas machine operator certification tends to be less formalized and varies by employer.

Daily Tasks Comparison

Machine operators primarily handle the setup, monitoring, and maintenance of machinery to ensure smooth production flow, while machinists focus on precision measuring, cutting, and shaping of metal parts using specialized tools. Operators typically follow set programs and troubleshoot equipment malfunctions, whereas machinists interpret technical blueprints and conduct quality inspections to meet exact specifications. Daily tasks for operators emphasize machine efficiency and output, whereas machinists prioritize accuracy and craftsmanship in metal fabrication.

Equipment Operated by Each Position

Machine operators typically handle automated or semi-automated equipment such as CNC machines, presses, and conveyor systems, focusing on setting up, monitoring, and maintaining production machinery. Machinists operate precise machine tools including lathes, milling machines, grinders, and drill presses, often programming and adjusting devices to create detailed metal parts. The distinction lies in the machinist's skill in interpreting blueprints and performing intricate manual adjustments, while machine operators manage broader production line equipment.

Work Environments and Settings

Machine operators typically work in high-volume production facilities, operating standardized machinery on assembly lines with repetitive tasks in controlled environments. Machinists are often found in workshops or custom job shops, working with precision tools to create or modify parts, requiring close attention to detail and varied work settings. Both roles demand adherence to safety protocols, but machinists generally experience more hands-on interaction with diverse materials and complex machinery setups.

Career Pathways and Advancement Opportunities

Machine operators typically follow a career pathway starting with entry-level skills and progressing to specialized equipment operation, often advancing to supervisory or maintenance roles. Machinists possess advanced technical expertise in precision tool operation, enabling career growth into CNC programming, tool design, or quality control management. Both roles offer upward mobility, but machinists generally access higher-paying positions due to their specialized training and certification options.

Average Salary and Compensation

Machine operators in manufacturing typically earn an average salary ranging from $35,000 to $50,000 annually, depending on experience and location. Machinists, who require more advanced technical skills and training, often command higher compensation, with average salaries between $45,000 and $65,000 per year. Benefits and overtime opportunities can further increase total compensation for both roles within industrial settings.

Choosing Between a Machine Operator and Machinist Career

Choosing between a machine operator and machinist career depends on skill level and job responsibilities; machine operators typically handle equipment setup and basic machine functions, while machinists require advanced technical skills to program, maintain, and troubleshoot precision machinery. Machine operators usually follow production schedules and maintain safety standards, whereas machinists focus on interpreting blueprints and ensuring parts meet exact specifications. Career growth and salary prospects are generally higher for machinists due to their specialized expertise and training.

Machine Operator vs Machinist Infographic

jobdiv.com

jobdiv.com