Forklift operators handle large loads with increased speed and efficiency, maneuvering heavy pallets in warehouses and construction sites, while pallet jack operators primarily move lighter loads over shorter distances using manual or electric jacks. Forklift operation requires specialized training and certification due to the complexity and safety risks of using powered industrial trucks. Pallet jack operators benefit from easier maneuverability and lower operational costs but have limitations in load capacity and height reach compared to forklifts.

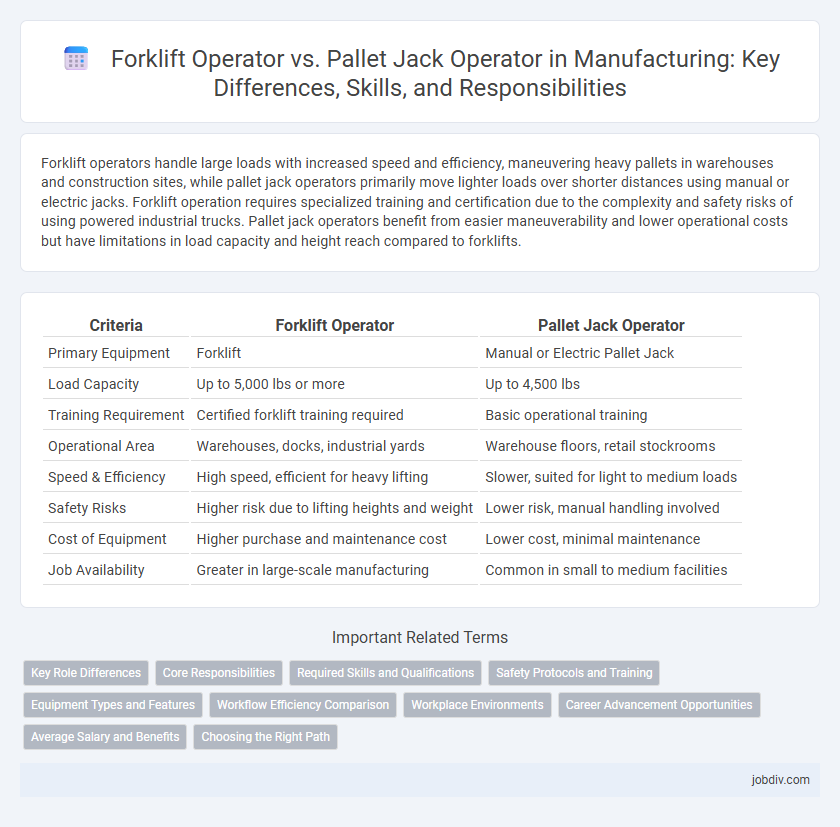

Table of Comparison

| Criteria | Forklift Operator | Pallet Jack Operator |

|---|---|---|

| Primary Equipment | Forklift | Manual or Electric Pallet Jack |

| Load Capacity | Up to 5,000 lbs or more | Up to 4,500 lbs |

| Training Requirement | Certified forklift training required | Basic operational training |

| Operational Area | Warehouses, docks, industrial yards | Warehouse floors, retail stockrooms |

| Speed & Efficiency | High speed, efficient for heavy lifting | Slower, suited for light to medium loads |

| Safety Risks | Higher risk due to lifting heights and weight | Lower risk, manual handling involved |

| Cost of Equipment | Higher purchase and maintenance cost | Lower cost, minimal maintenance |

| Job Availability | Greater in large-scale manufacturing | Common in small to medium facilities |

Key Role Differences

Forklift operators handle heavy loads and operate large machinery to move pallets across warehouses or production floors, requiring certification and extensive training for safe operation. Pallet jack operators maneuver smaller, more manual or electric pallet jacks primarily for short-distance pallet movement, involving less formal training but precise control in tight spaces. Key role differences revolve around equipment complexity, load capacity, operator certification, and the scale of material handling tasks within manufacturing facilities.

Core Responsibilities

Forklift operators are responsible for safely lifting, moving, and stacking heavy materials using powered forklifts, ensuring efficient transport within warehouses or manufacturing plants. Pallet jack operators primarily handle the manual or electric pallet jacks to move lighter loads over short distances, facilitating quick material flow on production floors. Both roles require adherence to safety protocols and precise load handling to maintain operational efficiency and prevent workplace accidents.

Required Skills and Qualifications

Forklift operators must possess comprehensive knowledge of safety protocols, load handling, and equipment maintenance, typically requiring certification and experience with heavy machinery. Pallet jack operators need proficiency in manual or electric pallet jack operation, spatial awareness, and basic safety training, often with less formal certification than forklift operators. Both roles demand physical stamina, attention to detail, and adherence to workplace safety standards to ensure efficient material handling in manufacturing environments.

Safety Protocols and Training

Forklift operators require comprehensive safety training to manage heavy machinery, including certifications that cover load handling, equipment inspection, and operational hazards. Pallet jack operators undergo focused safety protocols emphasizing manual handling techniques, weight limits, and proper navigation in tight warehouse spaces. Both roles prioritize adherence to OSHA standards to prevent workplace accidents and ensure efficient material handling.

Equipment Types and Features

Forklift operators typically use powered industrial trucks designed for lifting and transporting heavy loads with high reach capabilities, including sit-down and stand-up forklifts equipped with hydraulic lift systems and various attachments. Pallet jack operators handle manual or electric pallet jacks, which are smaller, more maneuverable equipment primarily designed for moving palletized goods over short distances with limited lifting height. Forklifts offer greater load capacity and versatility, while pallet jacks provide efficiency in tight spaces and for lower-weight materials handling tasks.

Workflow Efficiency Comparison

Forklift operators handle heavier loads and reach higher storage areas, significantly boosting workflow efficiency in large warehouses and manufacturing plants. Pallet jack operators excel in navigating tight spaces and performing quick, short-distance moves, enhancing productivity in smaller or cluttered environments. Choosing the right operator depends on specific material handling needs, with forklifts maximizing load capacity and pallet jacks optimizing maneuverability for streamlined workflow efficiency.

Workplace Environments

Forklift operators typically work in larger warehouses, distribution centers, and manufacturing plants where heavy loads and high stacking are common, requiring ample space and specialized safety protocols. Pallet jack operators usually handle lighter loads in more confined areas such as retail stockrooms, small warehouses, and loading docks where maneuverability and speed are prioritized. Both roles demand strict adherence to OSHA safety standards, but environmental factors like airflow, lighting, and floor surfaces significantly impact operational efficiency and worker safety.

Career Advancement Opportunities

Forklift operators often access higher-paying roles and supervisory positions due to their ability to handle a wider range of machinery and certifications, increasing their career advancement opportunities significantly. Pallet jack operators typically start in entry-level roles with fewer certification requirements, which may limit rapid progression but provide essential experience for moving into forklift operation. Both career paths benefit from continuous safety training and skill development, which are critical for promotion within the manufacturing industry.

Average Salary and Benefits

Forklift operators in manufacturing typically earn an average salary of $38,000 to $45,000 per year, reflecting the higher skill level and certification required compared to pallet jack operators, whose salaries range from $28,000 to $35,000 annually. Benefits for forklift operators often include comprehensive health insurance, retirement plans, and paid training programs, while pallet jack operators may receive more basic benefits packages with limited advancement opportunities. Salary and benefits can vary by region and company size, with unionized workplaces generally offering better compensation for both roles.

Choosing the Right Path

Choosing the right path between a forklift operator and pallet jack operator role depends on factors like equipment complexity, workload, and skill level. Forklift operators handle heavier loads and require specialized training and certification, often leading to higher wages and more responsibilities. Pallet jack operators focus on lighter materials and maneuverability in tighter spaces, making it ideal for entry-level positions or facilities with less demanding logistical needs.

Forklift Operator vs Pallet Jack Operator Infographic

jobdiv.com

jobdiv.com