Toolmakers specialize in creating precision tools, dies, and molds used in manufacturing processes, ensuring high accuracy and durability for mass production. Die makers focus specifically on designing and fabricating dies for cutting, shaping, and forming metal parts, playing a crucial role in stamping and forging operations. Both professions require deep technical expertise and contribute significantly to optimizing manufacturing efficiency and product quality.

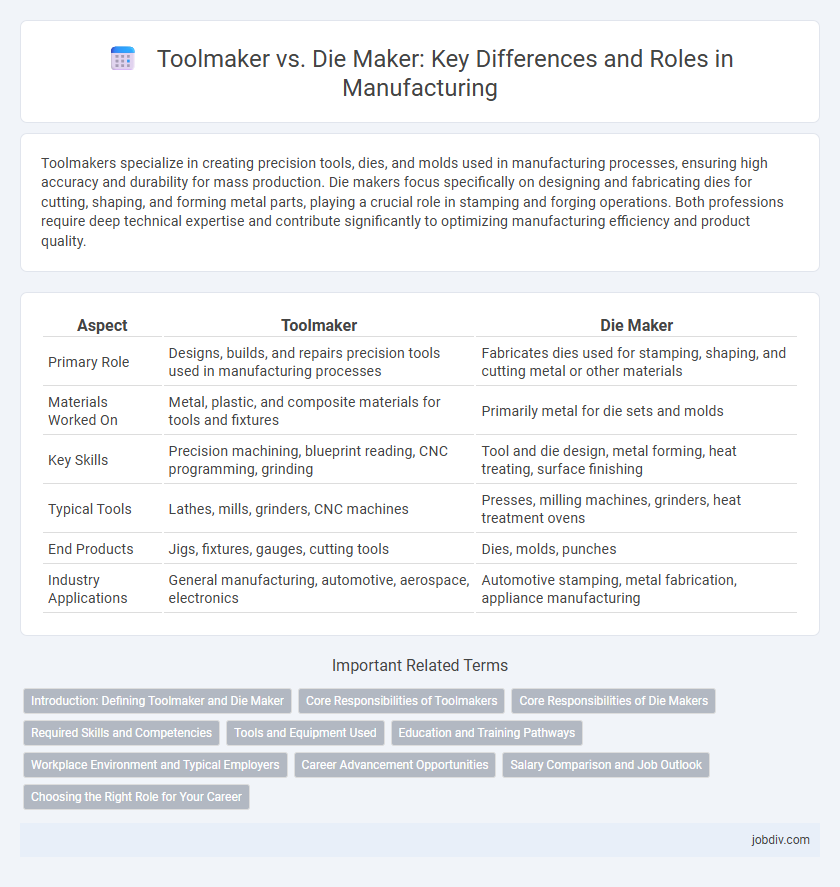

Table of Comparison

| Aspect | Toolmaker | Die Maker |

|---|---|---|

| Primary Role | Designs, builds, and repairs precision tools used in manufacturing processes | Fabricates dies used for stamping, shaping, and cutting metal or other materials |

| Materials Worked On | Metal, plastic, and composite materials for tools and fixtures | Primarily metal for die sets and molds |

| Key Skills | Precision machining, blueprint reading, CNC programming, grinding | Tool and die design, metal forming, heat treating, surface finishing |

| Typical Tools | Lathes, mills, grinders, CNC machines | Presses, milling machines, grinders, heat treatment ovens |

| End Products | Jigs, fixtures, gauges, cutting tools | Dies, molds, punches |

| Industry Applications | General manufacturing, automotive, aerospace, electronics | Automotive stamping, metal fabrication, appliance manufacturing |

Introduction: Defining Toolmaker and Die Maker

Toolmakers specialize in crafting precision tools, gauges, and specialized instruments essential for manufacturing processes, ensuring components meet exact specifications. Die makers focus on designing and building dies used in stamping, cutting, and forming operations to shape raw materials in mass production. Both roles require expertise in metallurgy, machining, and blueprint interpretation within industrial manufacturing settings.

Core Responsibilities of Toolmakers

Toolmakers specialize in creating precision tools, gauges, and cutting instruments essential for manufacturing processes, ensuring high accuracy and functionality. They interpret engineering drawings and use CNC machinery, grinding, and milling equipment to produce custom tools that meet exact specifications. Their core responsibilities include maintaining tool quality, performing adjustments, and troubleshooting to support efficient production workflows.

Core Responsibilities of Die Makers

Die makers specialize in designing, constructing, and maintaining dies used for stamping, cutting, and shaping metal parts with precision. Their core responsibilities include interpreting engineering blueprints, selecting appropriate materials, and ensuring the functionality and accuracy of dies in high-volume production environments. Expertise in CNC machining, grinding, and assembly is critical for die makers to produce durable tools that meet exact specifications and withstand repetitive use.

Required Skills and Competencies

Toolmakers require advanced skills in precision machining, blueprint reading, and knowledge of CNC programming to create and repair cutting tools and molds. Die makers specialize in fabricating dies, demanding expertise in metal forming techniques, welding, and close attention to detail for assembly and fitting. Both roles require strong problem-solving abilities, mechanical aptitude, and proficiency in using measuring instruments such as micrometers and calipers.

Tools and Equipment Used

Toolmakers primarily use precision machines such as CNC milling machines, lathes, and grinding machines to craft and maintain cutting tools, gauges, and jigs. Die makers specialize in equipment like press brakes, die sinks, EDM (Electrical Discharge Machines), and surface grinders to create and repair dies that shape or cut materials in mass production. Both roles rely heavily on CAD/CAM software and measuring instruments like micrometers and CMMs (Coordinate Measuring Machines) to ensure exact specifications.

Education and Training Pathways

Toolmakers typically require a combination of formal education in machining or manufacturing technology and extensive hands-on apprenticeship training to develop precision skills. Die makers often pursue specialized vocational programs focused on tool and die design, supplemented by on-the-job training to master complex metal forming techniques. Both career paths demand continuous skill development in CNC programming, metallurgy, and blueprint interpretation to excel in manufacturing environments.

Workplace Environment and Typical Employers

Toolmakers typically work in controlled manufacturing facilities specializing in precision machinery, often employed by automotive, aerospace, and electronics companies focused on creating high-quality tools and instruments. Die makers operate in similarly precise environments but are more commonly found in industries such as metal stamping, plastic molding, and forging firms, where they design and maintain dies used for mass production. Both professions require access to advanced machinery and CAD software, but the workplace atmosphere varies slightly based on industry-specific safety standards and production demands.

Career Advancement Opportunities

Toolmakers often have broader career advancement opportunities due to their expertise in creating and repairing precision tools used across multiple manufacturing processes. Die makers specialize in crafting dies used primarily in stamping and forging, which can limit their advancement to niche roles within specific industries. Both positions benefit from continuous skill development, but toolmakers typically transition more easily into supervisory, engineering, or quality control roles.

Salary Comparison and Job Outlook

Toolmakers typically earn a median annual salary of around $50,000 to $65,000, while die makers often command slightly higher wages, ranging from $55,000 to $70,000 due to the specialized skills required in die design and fabrication. The job outlook for both professions remains stable, with a projected growth rate of approximately 3% over the next decade, driven by ongoing demand in automotive, aerospace, and precision manufacturing sectors. Increased adoption of CNC and automation technologies continues to influence skill requirements, favoring candidates with advanced technical training and experience.

Choosing the Right Role for Your Career

Toolmakers specialize in creating precision tools and instrumentation essential for manufacturing processes, emphasizing versatility in various industries like automotive and aerospace. Die makers focus on fabricating dies used in shaping and cutting materials, playing a critical role in mass production and metal stamping operations. Selecting the right career depends on your interest in precision tool fabrication versus die crafting, as well as the specific industries and technologies you aim to work with.

Toolmaker vs Die Maker Infographic

jobdiv.com

jobdiv.com