Machine operators specialize in controlling and maintaining automated machinery used in production processes, ensuring efficient and accurate operation. Equipment operators handle larger, often mobile machinery such as forklifts or cranes, focusing on transportation and positioning of materials within the manufacturing site. Both roles require technical skills but differ in machinery type and operational scope within the manufacturing environment.

Table of Comparison

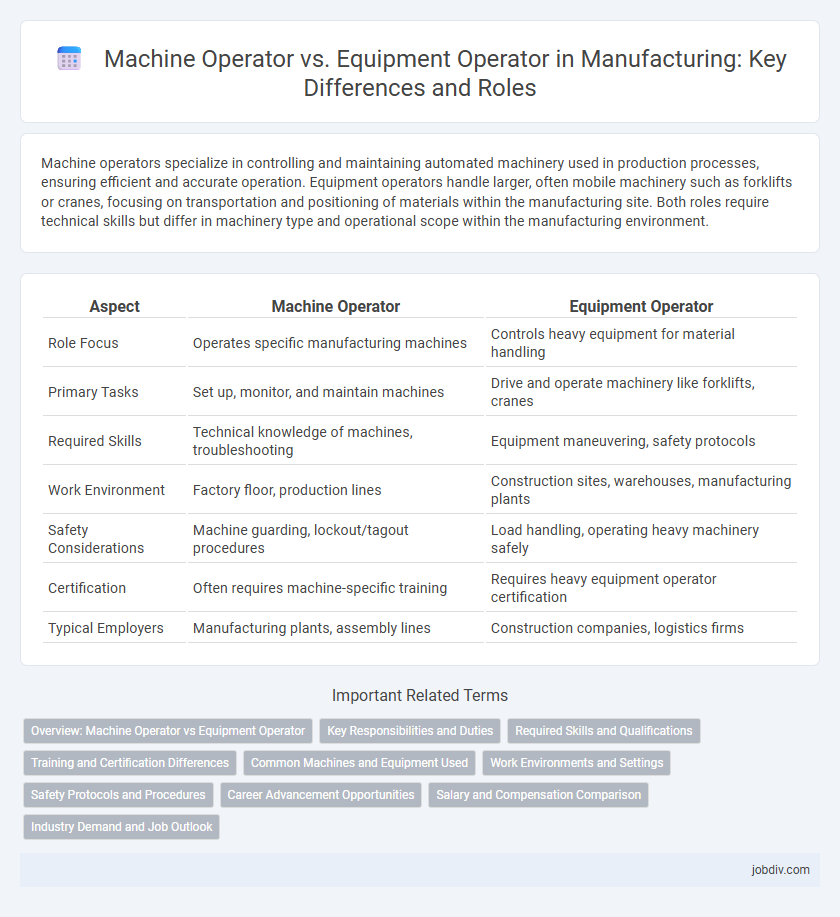

| Aspect | Machine Operator | Equipment Operator |

|---|---|---|

| Role Focus | Operates specific manufacturing machines | Controls heavy equipment for material handling |

| Primary Tasks | Set up, monitor, and maintain machines | Drive and operate machinery like forklifts, cranes |

| Required Skills | Technical knowledge of machines, troubleshooting | Equipment maneuvering, safety protocols |

| Work Environment | Factory floor, production lines | Construction sites, warehouses, manufacturing plants |

| Safety Considerations | Machine guarding, lockout/tagout procedures | Load handling, operating heavy machinery safely |

| Certification | Often requires machine-specific training | Requires heavy equipment operator certification |

| Typical Employers | Manufacturing plants, assembly lines | Construction companies, logistics firms |

Overview: Machine Operator vs Equipment Operator

Machine operators specialize in controlling and monitoring specific machinery used in manufacturing processes, ensuring precise operation and product quality. Equipment operators handle a broader range of heavy or specialized equipment, such as forklifts or cranes, essential for material movement and site logistics. Both roles require technical skills and safety knowledge but differ in the scope of machinery handled and operational focus.

Key Responsibilities and Duties

Machine Operators specialize in running and maintaining specific manufacturing machines, ensuring precise operation and consistent product quality. Equipment Operators handle a broader range of industrial machinery, including forklifts, cranes, and other heavy equipment, focusing on safe and efficient material handling. Both roles require adherence to safety protocols, routine inspections, and troubleshooting to minimize downtime and maintain production flow.

Required Skills and Qualifications

Machine Operators require technical skills in operating CNC machines, mechanical aptitude, and the ability to read blueprints and manuals, often needing certifications in machine safety and precision measurement tools. Equipment Operators focus on heavy machinery handling, hydraulic systems knowledge, and physical endurance, typically requiring licenses for operating forklifts, cranes, or earth-moving equipment. Both roles demand strong attention to detail, safety compliance, and basic troubleshooting abilities, but their qualifications differ based on the specificity of machines or equipment managed.

Training and Certification Differences

Machine operators typically undergo specialized training focused on the operation, maintenance, and troubleshooting of specific machinery, often requiring certifications like OSHA safety standards or industry-specific credentials. Equipment operators receive broader training encompassing various types of heavy machinery, such as forklifts or cranes, with certifications like NCCCO or forklift operator licenses being mandatory for compliance and safety. The distinct certification pathways reflect the technical skills and safety knowledge required uniquely for machine operation versus general equipment handling in manufacturing environments.

Common Machines and Equipment Used

Machine operators commonly work with CNC machines, lathes, and milling machines, which require precise control and programming skills. Equipment operators typically handle heavy machinery such as forklifts, cranes, and bulldozers, focusing on material handling and site preparation. Both roles are essential in manufacturing, ensuring efficient production and operational safety with specialized tools and machinery.

Work Environments and Settings

Machine operators typically work in controlled manufacturing environments such as assembly lines, where precision and consistency are crucial. Equipment operators often handle heavy machinery outdoors or in construction sites, requiring adaptability to variable weather and terrain conditions. Both roles demand adherence to safety protocols but differ significantly in the typical setting and operational context.

Safety Protocols and Procedures

Machine operators and equipment operators both play crucial roles in manufacturing, yet safety protocols differ slightly due to the nature of their tasks. Machine operators must follow strict lockout/tagout procedures to prevent accidental startups during maintenance, while equipment operators emphasize safe handling and operation of heavy machinery to avoid accidents. Both roles require comprehensive training on personal protective equipment (PPE), emergency stop mechanisms, and adherence to OSHA safety standards to minimize workplace hazards.

Career Advancement Opportunities

Machine operators often have specialized skills in handling specific machinery, leading to opportunities in technical roles such as CNC programming or machine maintenance. Equipment operators, experienced with a broader range of heavy machinery, can advance into supervisory or safety coordination positions within manufacturing plants. Both career paths offer growth potential, but machine operators typically progress through technical expertise while equipment operators leverage operational versatility for leadership roles.

Salary and Compensation Comparison

Machine operators in manufacturing typically earn an average annual salary ranging from $35,000 to $50,000, while equipment operators can command higher wages, often between $40,000 and $60,000, reflecting the greater technical skill and responsibility required. Compensation packages for equipment operators frequently include additional benefits such as overtime pay, bonuses, and hazard pay, contributing to a more lucrative overall income. Salary variations depend on factors like industry, geographic location, and experience, with specialized equipment operators generally receiving premium pay compared to general machine operators.

Industry Demand and Job Outlook

Machine operators and equipment operators both play crucial roles in manufacturing, with machine operators typically handling specialized machinery while equipment operators manage broader mechanical systems. Industry demand for machine operators remains strong due to increasing automation and the need for skilled technicians to maintain precision equipment. Job outlook for equipment operators is steady, driven by infrastructure projects and manufacturing plants seeking efficient operation of heavy machinery.

Machine Operator vs Equipment Operator Infographic

jobdiv.com

jobdiv.com