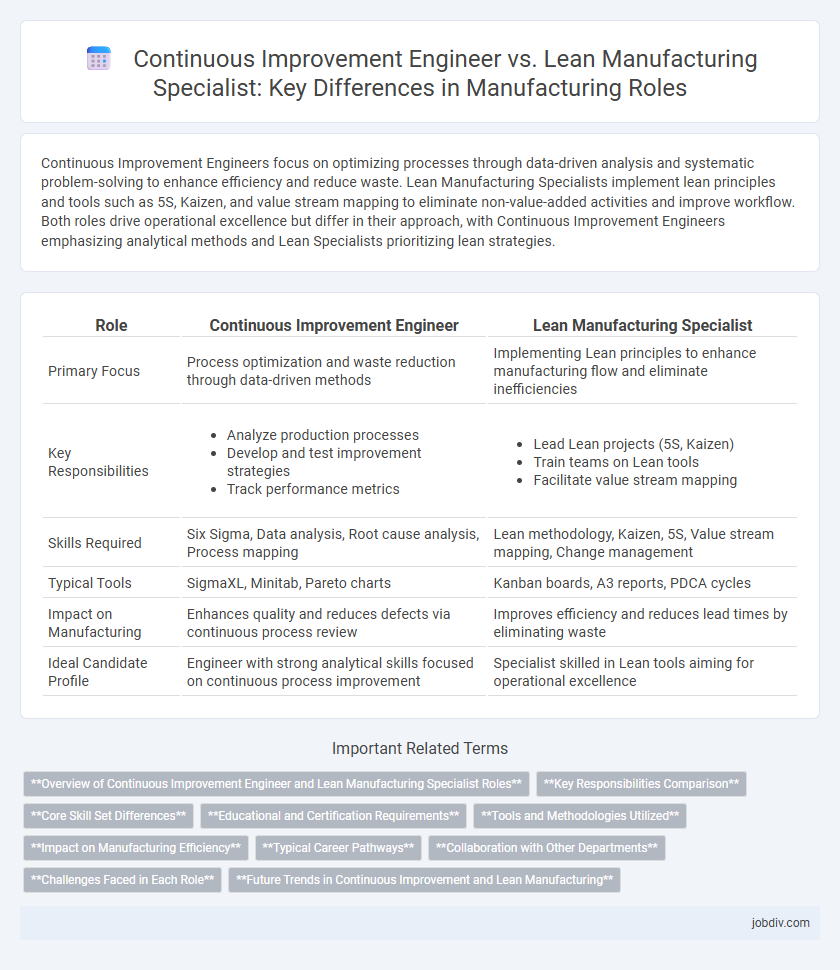

Continuous Improvement Engineers focus on optimizing processes through data-driven analysis and systematic problem-solving to enhance efficiency and reduce waste. Lean Manufacturing Specialists implement lean principles and tools such as 5S, Kaizen, and value stream mapping to eliminate non-value-added activities and improve workflow. Both roles drive operational excellence but differ in their approach, with Continuous Improvement Engineers emphasizing analytical methods and Lean Specialists prioritizing lean strategies.

Table of Comparison

| Role | Continuous Improvement Engineer | Lean Manufacturing Specialist |

|---|---|---|

| Primary Focus | Process optimization and waste reduction through data-driven methods | Implementing Lean principles to enhance manufacturing flow and eliminate inefficiencies |

| Key Responsibilities |

|

|

| Skills Required | Six Sigma, Data analysis, Root cause analysis, Process mapping | Lean methodology, Kaizen, 5S, Value stream mapping, Change management |

| Typical Tools | SigmaXL, Minitab, Pareto charts | Kanban boards, A3 reports, PDCA cycles |

| Impact on Manufacturing | Enhances quality and reduces defects via continuous process review | Improves efficiency and reduces lead times by eliminating waste |

| Ideal Candidate Profile | Engineer with strong analytical skills focused on continuous process improvement | Specialist skilled in Lean tools aiming for operational excellence |

Overview of Continuous Improvement Engineer and Lean Manufacturing Specialist Roles

A Continuous Improvement Engineer focuses on systematically enhancing manufacturing processes by identifying inefficiencies and implementing data-driven solutions to boost productivity and quality. A Lean Manufacturing Specialist emphasizes the application of Lean principles and tools such as value stream mapping, Kaizen, and 5S to eliminate waste and optimize workflow within production environments. Both roles collaborate closely with cross-functional teams to foster a culture of continuous improvement and operational excellence in manufacturing facilities.

Key Responsibilities Comparison

Continuous Improvement Engineers focus on identifying process inefficiencies and implementing data-driven solutions to enhance productivity, quality, and cost-effectiveness across manufacturing operations. Lean Manufacturing Specialists concentrate on applying Lean principles such as waste reduction, value stream mapping, and just-in-time production to streamline workflows and improve overall operational efficiency. Both roles require strong analytical skills, but Continuous Improvement Engineers often utilize Six Sigma methodologies, whereas Lean Specialists emphasize Lean tools and cultural change within teams.

Core Skill Set Differences

Continuous Improvement Engineers excel in data-driven problem-solving, process optimization, and Six Sigma methodologies to enhance manufacturing efficiency and quality. Lean Manufacturing Specialists focus on waste reduction, value stream mapping, and implementing lean principles like 5S, Kaizen, and Just-in-Time production. The core skill set differences lie in the Continuous Improvement Engineer's emphasis on quantitative analysis and statistical tools versus the Lean Manufacturing Specialist's expertise in lean tools and cultural change facilitation.

Educational and Certification Requirements

Continuous Improvement Engineers typically require a bachelor's degree in industrial engineering, manufacturing engineering, or a related field, often complemented by certifications such as Six Sigma Green Belt or Black Belt. Lean Manufacturing Specialists usually hold a similar educational background but emphasize certifications in Lean methodologies, including Lean Six Sigma, Kaizen, and Value Stream Mapping. Both roles benefit from ongoing professional development through workshops and advanced certifications to stay current with industry best practices.

Tools and Methodologies Utilized

Continuous Improvement Engineers primarily utilize Six Sigma, Kaizen, and PDCA (Plan-Do-Check-Act) cycles to analyze processes and implement incremental improvements. Lean Manufacturing Specialists focus on value stream mapping, 5S methodology, and just-in-time (JIT) production techniques to eliminate waste and enhance flow efficiency. Both roles employ root cause analysis tools such as Fishbone diagrams and Pareto charts to optimize manufacturing operations.

Impact on Manufacturing Efficiency

Continuous Improvement Engineers systematically enhance manufacturing processes by identifying inefficiencies and implementing data-driven solutions, which leads to significant reductions in cycle time and operational costs. Lean Manufacturing Specialists focus on waste elimination and optimizing value streams through lean principles, driving improved workflow efficiency and increased production output. Both roles critically impact manufacturing efficiency, but Continuous Improvement Engineers emphasize process optimization while Lean Specialists prioritize waste reduction.

Typical Career Pathways

A Continuous Improvement Engineer typically advances from roles such as Process Engineer or Quality Analyst, progressing toward positions like Continuous Improvement Manager or Operations Manager, emphasizing cross-functional skills in process optimization and data analysis. Lean Manufacturing Specialists often begin as Production Supervisors or Manufacturing Technicians, developing expertise in lean principles before moving into Lean Coordinator or Lean Strategist roles, focusing on waste reduction and value stream mapping. Both career pathways converge toward leadership roles in operational excellence, with Continuous Improvement Engineers leveraging engineering methodologies and Lean Specialists specializing in lean tools and cultural transformation.

Collaboration with Other Departments

Continuous Improvement Engineers foster cross-functional teamwork by integrating feedback from production, quality control, and supply chain departments to streamline processes and enhance efficiency. Lean Manufacturing Specialists work closely with operations, procurement, and engineering teams to implement waste reduction strategies and optimize workflow. Both roles emphasize collaborative problem-solving to drive sustainable improvements across manufacturing units.

Challenges Faced in Each Role

Continuous Improvement Engineers often face challenges in identifying inefficiencies across complex production systems and integrating new processes without disrupting existing workflows. Lean Manufacturing Specialists struggle with overcoming resistance to cultural change among employees and ensuring sustainable implementation of lean principles on the factory floor. Both roles require strong problem-solving skills to address operational bottlenecks and drive measurable productivity gains.

Future Trends in Continuous Improvement and Lean Manufacturing

Future trends in continuous improvement and lean manufacturing emphasize the integration of advanced technologies such as artificial intelligence, machine learning, and IoT to optimize production processes and enhance real-time decision-making. Continuous Improvement Engineers increasingly leverage data analytics and predictive maintenance to drive efficiency, while Lean Manufacturing Specialists focus on eliminating waste through smarter automation and digital lean tools. The convergence of digital transformation with lean principles accelerates innovation, sustainability, and operational agility across manufacturing industries.

Continuous Improvement Engineer vs Lean Manufacturing Specialist Infographic

jobdiv.com

jobdiv.com