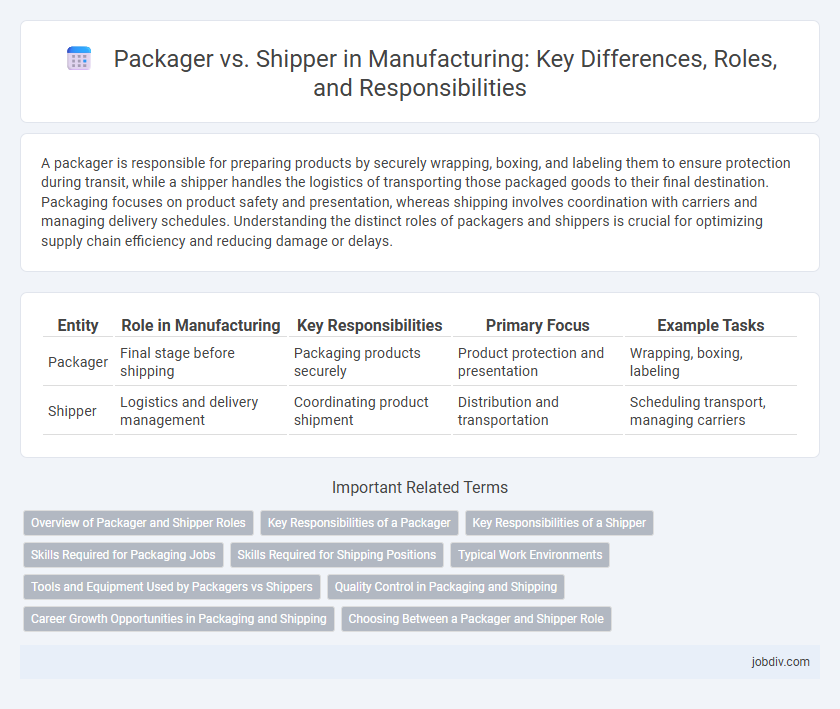

A packager is responsible for preparing products by securely wrapping, boxing, and labeling them to ensure protection during transit, while a shipper handles the logistics of transporting those packaged goods to their final destination. Packaging focuses on product safety and presentation, whereas shipping involves coordination with carriers and managing delivery schedules. Understanding the distinct roles of packagers and shippers is crucial for optimizing supply chain efficiency and reducing damage or delays.

Table of Comparison

| Entity | Role in Manufacturing | Key Responsibilities | Primary Focus | Example Tasks |

|---|---|---|---|---|

| Packager | Final stage before shipping | Packaging products securely | Product protection and presentation | Wrapping, boxing, labeling |

| Shipper | Logistics and delivery management | Coordinating product shipment | Distribution and transportation | Scheduling transport, managing carriers |

Overview of Packager and Shipper Roles

Packagers focus on preparing products by securely wrapping, labeling, and assembling items to ensure protection and presentation during transit. Shippers coordinate the logistics of transporting packaged goods, managing carrier selection, documentation, and delivery schedules to optimize supply chain efficiency. Both roles are critical in manufacturing for maintaining product integrity from production to final destination.

Key Responsibilities of a Packager

A packager in manufacturing is responsible for assembling, wrapping, and labeling products to ensure they meet quality standards and are protected during transit. They operate packing machinery, inspect materials for defects, and maintain accurate documentation of packed items. Ensuring compliance with safety regulations and optimizing packaging efficiency are critical duties to support seamless supply chain operations.

Key Responsibilities of a Shipper

A shipper in manufacturing is responsible for coordinating the transportation of finished goods from the warehouse to customers, ensuring timely and accurate order fulfillment. Key duties include organizing shipping documents, selecting appropriate carriers, and tracking shipments to monitor delivery status. This role also involves compliance with shipping regulations and optimizing logistics to reduce costs and improve supply chain efficiency.

Skills Required for Packaging Jobs

Packaging jobs demand strong attention to detail, manual dexterity, and knowledge of material handling procedures to ensure products are securely packed. Proficiency in operating packaging machinery, understanding safety regulations, and quality control measures are essential for maintaining product integrity. Effective communication skills and the ability to follow precise instructions support efficient packaging workflows and minimize errors.

Skills Required for Shipping Positions

Shipping positions demand expertise in inventory management, order processing, and logistics coordination to ensure accurate and timely delivery. Proficiency in operating shipping software, understanding freight documentation, and handling hazardous materials compliance are essential skills. Effective communication, problem-solving abilities, and physical stamina enhance performance in fast-paced warehouse environments.

Typical Work Environments

Packagers typically work in assembly lines, warehouses, or production facilities where they handle product wrapping, labeling, and boxing. Shippers operate in loading docks, distribution centers, or logistics hubs, focusing on organizing and dispatching shipments for transport. Both roles demand adherence to safety protocols and efficiency in fast-paced, industrial environments.

Tools and Equipment Used by Packagers vs Shippers

Packagers primarily use sealing machines, labeling systems, and automated wrapping equipment to ensure products are securely enclosed and ready for transit. Shippers rely on forklifts, pallet jacks, and loading docks to efficiently move and load packaged goods onto transportation vehicles. The integration of barcode scanners and inventory management software enhances accuracy and traceability in both packaging and shipping operations.

Quality Control in Packaging and Shipping

Quality control in packaging ensures products are sealed, labeled, and protected to maintain integrity and prevent damage during transit. The packager's role centers on verifying that packaging materials meet specifications and that products are securely contained to avoid contamination or spoilage. Shippers focus on inspecting shipment conditions, confirming load stability, and ensuring compliance with transportation standards to minimize risks during distribution.

Career Growth Opportunities in Packaging and Shipping

Career growth opportunities in packaging emphasize skill development in materials handling, quality control, and automation technology, leading to roles such as packaging supervisor or production manager. Shipping careers offer advancement through expertise in logistics, inventory management, and supply chain coordination, progressing toward dispatcher or logistics manager positions. Both fields provide pathways to higher responsibility roles within manufacturing operations, with packaging focusing more on product preparation and shipping centered on distribution and delivery efficiency.

Choosing Between a Packager and Shipper Role

Choosing between a packager and shipper role depends on core logistics responsibilities; packagers specialize in preparing and securing products for transit, ensuring damage prevention through optimal packaging materials and techniques. Shippers focus on managing transportation, coordinating carriers, and tracking shipments to guarantee timely delivery and compliance with shipping regulations. Understanding supply chain demands and cost-efficiency priorities guides manufacturers in selecting the most strategic role for operational success.

Packager vs Shipper Infographic

jobdiv.com

jobdiv.com