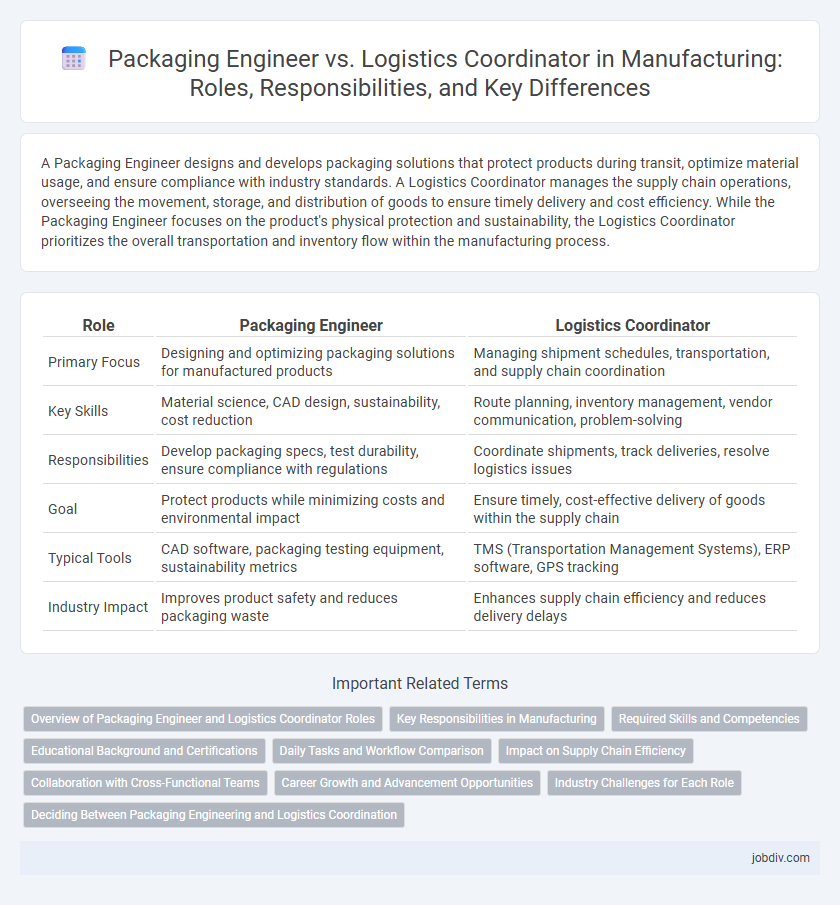

A Packaging Engineer designs and develops packaging solutions that protect products during transit, optimize material usage, and ensure compliance with industry standards. A Logistics Coordinator manages the supply chain operations, overseeing the movement, storage, and distribution of goods to ensure timely delivery and cost efficiency. While the Packaging Engineer focuses on the product's physical protection and sustainability, the Logistics Coordinator prioritizes the overall transportation and inventory flow within the manufacturing process.

Table of Comparison

| Role | Packaging Engineer | Logistics Coordinator |

|---|---|---|

| Primary Focus | Designing and optimizing packaging solutions for manufactured products | Managing shipment schedules, transportation, and supply chain coordination |

| Key Skills | Material science, CAD design, sustainability, cost reduction | Route planning, inventory management, vendor communication, problem-solving |

| Responsibilities | Develop packaging specs, test durability, ensure compliance with regulations | Coordinate shipments, track deliveries, resolve logistics issues |

| Goal | Protect products while minimizing costs and environmental impact | Ensure timely, cost-effective delivery of goods within the supply chain |

| Typical Tools | CAD software, packaging testing equipment, sustainability metrics | TMS (Transportation Management Systems), ERP software, GPS tracking |

| Industry Impact | Improves product safety and reduces packaging waste | Enhances supply chain efficiency and reduces delivery delays |

Overview of Packaging Engineer and Logistics Coordinator Roles

Packaging engineers design and develop packaging solutions to protect products during shipping, enhance shelf appeal, and optimize material use while ensuring compliance with industry standards. Logistics coordinators manage the transportation, warehousing, and distribution processes, focusing on efficient inventory flow, cost reduction, and timely delivery across supply chains. Both roles collaborate closely to streamline product movement from manufacturing to end customers, balancing packaging integrity with logistics efficiency.

Key Responsibilities in Manufacturing

Packaging Engineers design and develop packaging solutions that ensure product protection, cost efficiency, and compliance with industry standards, focusing on material selection, testing, and production integration. Logistics Coordinators manage the efficient movement, storage, and distribution of materials and finished goods, coordinating supply chain activities, inventory levels, and transportation schedules to optimize workflow. Both roles are critical in manufacturing, with Packaging Engineers focusing on product integrity during transit and Logistics Coordinators ensuring timely delivery and resource allocation.

Required Skills and Competencies

Packaging Engineers require expertise in materials science, structural design, and sustainability principles to develop efficient packaging solutions that protect products while minimizing costs. Logistics Coordinators must possess skills in supply chain management, inventory control, and real-time tracking technologies to ensure timely distribution and optimize transportation routes. Both roles demand strong analytical abilities, proficiency in relevant software tools, and effective communication skills to collaborate across manufacturing and distribution teams.

Educational Background and Certifications

Packaging Engineers typically possess a bachelor's degree in packaging science, mechanical engineering, or industrial design, often supplemented by certifications such as Certified Packaging Professional (CPP) to validate expertise in materials and product protection. Logistics Coordinators usually hold degrees in supply chain management, business administration, or logistics and may obtain certifications like Certified Supply Chain Professional (CSCP) or Certified in Logistics, Transportation and Distribution (CLTD) to enhance knowledge in transportation and distribution management. Both roles require specialized education and industry-recognized credentials to optimize efficiency in product handling and delivery processes.

Daily Tasks and Workflow Comparison

Packaging Engineers design and test packaging solutions to ensure product protection and cost efficiency, conducting material analysis and collaborating with production teams on packaging specifications. Logistics Coordinators manage inventory flow, coordinate shipment schedules, and track deliveries to optimize supply chain operations and meet distribution deadlines. Both roles require strong problem-solving skills but differ as Packaging Engineers focus on product containment and durability, while Logistics Coordinators oversee transportation logistics and warehouse management.

Impact on Supply Chain Efficiency

Packaging engineers optimize product protection and materials, reducing damage rates and enhancing storage efficiency, which directly lowers supply chain costs. Logistics coordinators manage transportation routes and inventory flow, ensuring timely deliveries and minimizing delays across distribution networks. Both roles critically enhance supply chain efficiency by improving packaging reliability and streamlining logistics operations.

Collaboration with Cross-Functional Teams

Packaging Engineers collaborate closely with design, production, and quality assurance teams to develop efficient, sustainable packaging solutions that reduce costs and improve product protection. Logistics Coordinators work alongside supply chain, warehouse, and transportation departments to optimize distribution strategies, ensuring timely delivery and inventory accuracy. Both roles require seamless communication and alignment with cross-functional teams to enhance overall manufacturing workflow and customer satisfaction.

Career Growth and Advancement Opportunities

Packaging Engineers in manufacturing often experience career growth through specialization in materials science, sustainability, and automation technologies, leading to roles such as Packaging Manager or Product Development Specialist. Logistics Coordinators advance by mastering supply chain optimization, inventory management, and transportation logistics, which can result in promotions to Logistics Manager or Supply Chain Director. Both paths offer strong advancement prospects, but Packaging Engineers typically leverage technical innovation for upward mobility, whereas Logistics Coordinators capitalize on operational efficiency and network expansion.

Industry Challenges for Each Role

Packaging Engineers face challenges such as designing sustainable, cost-effective packaging solutions that meet regulatory standards while protecting products during transit. Logistics Coordinators must manage complex supply chain disruptions, optimizing route efficiency and inventory control to prevent delays and reduce operational costs. Both roles require adaptive strategies to address increasing market demands and technological advancements in manufacturing.

Deciding Between Packaging Engineering and Logistics Coordination

Choosing between Packaging Engineering and Logistics Coordination hinges on expertise requirements: Packaging Engineers specialize in designing efficient, sustainable packaging solutions that enhance product protection and reduce materials cost, optimizing supply chain integrity. Logistics Coordinators focus on managing and streamlining the transportation, storage, and distribution processes to ensure timely global delivery and inventory control. Businesses prioritizing product design innovation and material efficiency opt for Packaging Engineers, while those emphasizing operational flow and distribution networks favor Logistics Coordinators.

Packaging Engineer vs Logistics Coordinator Infographic

jobdiv.com

jobdiv.com