Production schedulers focus on organizing manufacturing activities to ensure efficient use of resources and timely completion of production orders, while demand planners analyze market trends and customer data to forecast product demand accurately. Effective collaboration between production schedulers and demand planners minimizes inventory costs and prevents production bottlenecks. Aligning production schedules with demand forecasts enhances overall supply chain efficiency and responsiveness.

Table of Comparison

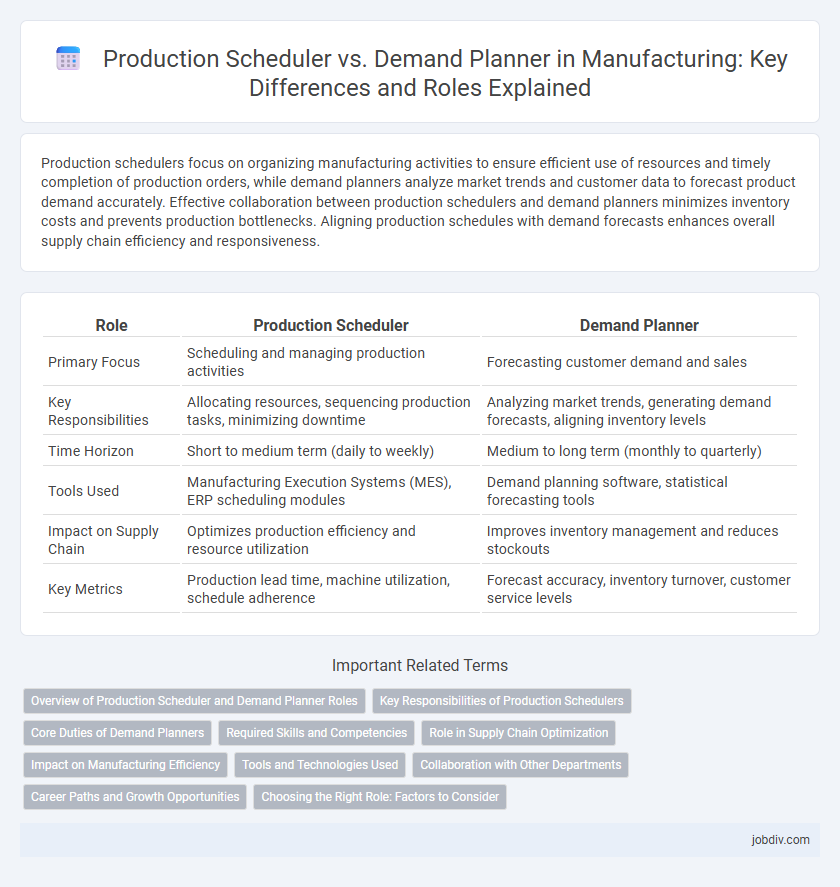

| Role | Production Scheduler | Demand Planner |

|---|---|---|

| Primary Focus | Scheduling and managing production activities | Forecasting customer demand and sales |

| Key Responsibilities | Allocating resources, sequencing production tasks, minimizing downtime | Analyzing market trends, generating demand forecasts, aligning inventory levels |

| Time Horizon | Short to medium term (daily to weekly) | Medium to long term (monthly to quarterly) |

| Tools Used | Manufacturing Execution Systems (MES), ERP scheduling modules | Demand planning software, statistical forecasting tools |

| Impact on Supply Chain | Optimizes production efficiency and resource utilization | Improves inventory management and reduces stockouts |

| Key Metrics | Production lead time, machine utilization, schedule adherence | Forecast accuracy, inventory turnover, customer service levels |

Overview of Production Scheduler and Demand Planner Roles

Production schedulers coordinate manufacturing activities, ensuring efficient allocation of resources and timely completion of production orders to meet delivery deadlines. Demand planners analyze market trends and historical sales data to forecast customer demand, enabling accurate inventory management and production planning. Both roles collaborate closely to balance supply and demand, optimize production schedules, and minimize excess inventory in manufacturing operations.

Key Responsibilities of Production Schedulers

Production schedulers are responsible for creating detailed manufacturing schedules that optimize resource utilization and ensure timely completion of production orders. They coordinate with procurement, inventory management, and production teams to align workflows with capacity constraints and delivery deadlines. Their key tasks include prioritizing job orders, monitoring production progress, and adjusting schedules to address bottlenecks and meet customer demand efficiently.

Core Duties of Demand Planners

Demand planners analyze historical sales data, market trends, and customer forecasts to create accurate demand projections that guide inventory and production levels. They collaborate with sales, marketing, and supply chain teams to align demand forecasts with business goals and minimize stockouts or excess inventory. Their core duties include demand forecasting, inventory optimization, sales data analysis, and coordinating with production schedulers to ensure manufacturing meets actual market demand.

Required Skills and Competencies

Production schedulers require strong organizational skills, proficiency in ERP systems, and the ability to manage inventory and production timelines efficiently, ensuring smooth workflow on the manufacturing floor. Demand planners must excel in data analysis, forecasting techniques, and cross-functional collaboration, leveraging statistical tools to predict customer demand and optimize supply chain operations. Both roles benefit from problem-solving abilities and effective communication skills, but production schedulers emphasize operational execution while demand planners focus on strategic planning and market trend analysis.

Role in Supply Chain Optimization

A Production Scheduler coordinates manufacturing processes by allocating resources and setting timelines to maximize efficiency and minimize downtime, playing a critical role in meeting production targets. A Demand Planner analyzes market trends, sales data, and forecasts to predict customer demand accurately, enabling inventory optimization and reducing stockouts or overproduction. Together, these roles ensure synchronized supply chain operations, improving responsiveness and cost-effectiveness in manufacturing workflows.

Impact on Manufacturing Efficiency

A Production Scheduler directly impacts manufacturing efficiency by optimizing work orders, machine utilization, and labor allocation to minimize downtime and bottlenecks. Demand Planners enhance efficiency indirectly by forecasting customer demand accurately, ensuring raw materials and components are available to prevent production delays. Together, effective scheduling and precise demand planning reduce inventory costs and improve on-time delivery performance, driving overall operational productivity.

Tools and Technologies Used

Production schedulers utilize advanced tools such as Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) software, and Gantt charts to optimize workflow, allocate resources, and ensure timely manufacturing processes. Demand planners rely on predictive analytics, machine learning algorithms, and demand forecasting software like SAP APO or Oracle Demantra to analyze historical sales data, market trends, and customer behavior for accurate demand prediction. Integration platforms and real-time data analytics enable seamless collaboration between production scheduling and demand planning, enhancing overall supply chain efficiency.

Collaboration with Other Departments

A Production Scheduler collaborates closely with the manufacturing, inventory, and quality control teams to ensure that production timelines align with capacity and resource availability. Demand Planners work with sales, marketing, and supply chain departments to accurately forecast customer demand and adjust inventory strategies accordingly. Strong communication between these roles and cross-functional teams drives efficient production workflows and minimizes stockouts or overproduction.

Career Paths and Growth Opportunities

Production Schedulers specialize in optimizing manufacturing workflows and resource allocation, often advancing into roles like Operations Manager or Supply Chain Director due to their hands-on production expertise. Demand Planners focus on forecasting market needs and inventory management, with career growth toward positions such as Demand Planning Manager or Sales and Operations Planning (S&OP) Leader. Both roles offer pathways to strategic supply chain leadership, but Demand Planners typically transition into data-driven analytics and market strategy roles, whereas Production Schedulers move into operational efficiency and production management.

Choosing the Right Role: Factors to Consider

Selecting between a production scheduler and a demand planner depends on your manufacturing priorities--production schedulers optimize equipment utilization and workflow sequences to meet immediate manufacturing deadlines, while demand planners focus on forecasting market demand and aligning inventory levels to customer requirements. Consider factors such as the complexity of your supply chain, variability in customer orders, and the need for real-time production adjustments versus long-term demand forecasting accuracy. Integrating data analytics tools and aligning the role with your strategic production goals ensures operational efficiency and cost-effectiveness.

Production Scheduler vs Demand Planner Infographic

jobdiv.com

jobdiv.com