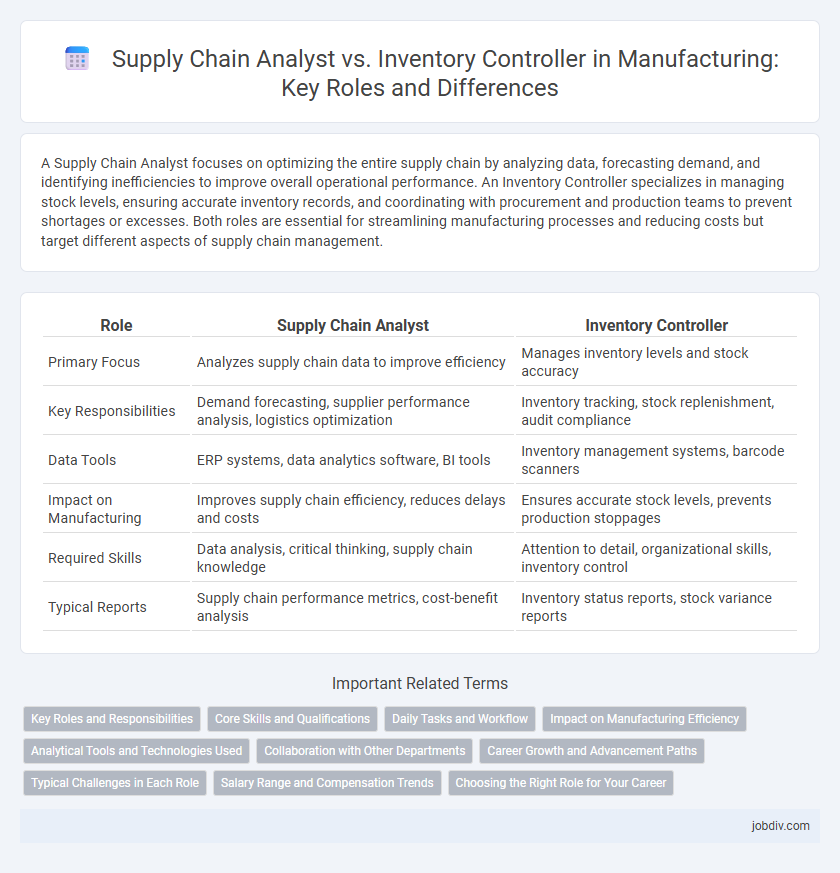

A Supply Chain Analyst focuses on optimizing the entire supply chain by analyzing data, forecasting demand, and identifying inefficiencies to improve overall operational performance. An Inventory Controller specializes in managing stock levels, ensuring accurate inventory records, and coordinating with procurement and production teams to prevent shortages or excesses. Both roles are essential for streamlining manufacturing processes and reducing costs but target different aspects of supply chain management.

Table of Comparison

| Role | Supply Chain Analyst | Inventory Controller |

|---|---|---|

| Primary Focus | Analyzes supply chain data to improve efficiency | Manages inventory levels and stock accuracy |

| Key Responsibilities | Demand forecasting, supplier performance analysis, logistics optimization | Inventory tracking, stock replenishment, audit compliance |

| Data Tools | ERP systems, data analytics software, BI tools | Inventory management systems, barcode scanners |

| Impact on Manufacturing | Improves supply chain efficiency, reduces delays and costs | Ensures accurate stock levels, prevents production stoppages |

| Required Skills | Data analysis, critical thinking, supply chain knowledge | Attention to detail, organizational skills, inventory control |

| Typical Reports | Supply chain performance metrics, cost-benefit analysis | Inventory status reports, stock variance reports |

Key Roles and Responsibilities

Supply Chain Analysts focus on analyzing data to optimize procurement, logistics, and distribution processes, ensuring efficient supply chain operations and cost reduction. Inventory Controllers manage stock levels, track inventory accuracy, and coordinate warehouse activities to prevent shortages or overstock situations. Both roles require strong analytical skills but differ in scope, with Supply Chain Analysts emphasizing strategic improvements and Inventory Controllers concentrating on daily inventory management.

Core Skills and Qualifications

Supply Chain Analysts excel in data analysis, forecasting, and process optimization, utilizing tools like SAP, SQL, and advanced Excel to enhance supply chain efficiency and reduce costs. Inventory Controllers focus on stock management, accuracy in inventory tracking, and demand planning, requiring strong organizational skills and experience with ERP systems such as Oracle or Microsoft Dynamics. Both roles demand analytical thinking and attention to detail, but Supply Chain Analysts emphasize strategic insights while Inventory Controllers prioritize operational inventory control.

Daily Tasks and Workflow

Supply Chain Analysts focus on analyzing data to optimize the flow of materials and improve forecasting accuracy, using ERP systems and demand planning software daily. Inventory Controllers manage stock levels, perform cycle counts, and coordinate with procurement and production teams to ensure inventory accuracy and avoid stockouts. Both roles require collaboration with suppliers and logistics teams, but Supply Chain Analysts emphasize strategic planning while Inventory Controllers prioritize operational efficiency.

Impact on Manufacturing Efficiency

Supply Chain Analysts enhance manufacturing efficiency by optimizing procurement, demand forecasting, and logistics, ensuring materials arrive on time and production lines run smoothly. Inventory Controllers maintain accurate stock levels and prevent production delays caused by shortages or overstocking, directly impacting operational continuity. Together, their roles streamline resource management, reduce downtime, and improve overall manufacturing throughput.

Analytical Tools and Technologies Used

Supply Chain Analysts utilize advanced analytical tools such as SAP Supply Chain Management, Tableau, and IBM Watson to forecast demand, optimize logistics, and analyze procurement data for strategic decision-making. Inventory Controllers rely on inventory management software like Oracle NetSuite, Microsoft Dynamics 365, and barcode scanning technologies to monitor stock levels, manage reorder points, and ensure accurate inventory records. Both roles integrate data analytics and ERP systems to enhance operational efficiency, but Supply Chain Analysts emphasize predictive modeling while Inventory Controllers focus on real-time inventory accuracy.

Collaboration with Other Departments

Supply Chain Analysts work closely with procurement, production, and logistics teams to optimize inventory levels and improve demand forecasting accuracy. Inventory Controllers collaborate primarily with warehouse and finance departments to maintain stock accuracy and manage inventory costs effectively. Both roles require seamless interdepartmental communication to enhance overall supply chain efficiency in manufacturing operations.

Career Growth and Advancement Paths

Supply Chain Analysts in manufacturing leverage data analytics and forecasting to optimize logistics and procurement, often advancing into roles such as Supply Chain Managers or Operations Directors due to their strategic impact on efficiency and cost reduction. Inventory Controllers focus on maintaining accurate stock levels and minimizing carrying costs, with career paths typically progressing toward Inventory Managers or Warehouse Operations Supervisors, emphasizing operational stability and process control. Both roles offer distinct advancement opportunities, with Supply Chain Analysts trending toward broader strategic responsibilities and Inventory Controllers specializing in detailed inventory management and operational excellence.

Typical Challenges in Each Role

Supply Chain Analysts often face challenges in demand forecasting accuracy, data integration from multiple sources, and optimizing logistics to reduce costs while maintaining service levels. Inventory Controllers encounter difficulties in maintaining optimal stock levels, preventing stockouts or excess inventory, and ensuring accurate inventory records through real-time monitoring. Both roles require managing variability and uncertainty, but Supply Chain Analysts focus more on strategic data analysis, whereas Inventory Controllers emphasize operational accuracy and control.

Salary Range and Compensation Trends

Supply Chain Analysts in manufacturing typically earn between $65,000 and $90,000 annually, reflecting their role in optimizing logistics and demand forecasting. Inventory Controllers usually have a salary range of $50,000 to $75,000, driven by responsibilities in stock management and inventory accuracy. Recent compensation trends indicate growing demand for data-driven skills, pushing Supply Chain Analyst salaries higher due to the increased reliance on analytics in supply chain efficiency.

Choosing the Right Role for Your Career

Supply Chain Analysts use data analytics and forecasting techniques to optimize procurement, production scheduling, and distribution processes, driving efficiency across the manufacturing value chain. Inventory Controllers focus on monitoring stock levels, managing reorder points, and minimizing carrying costs to ensure uninterrupted production and reduce waste. Choosing between these roles depends on your strengths in data-driven decision-making versus hands-on inventory management within manufacturing supply chains.

Supply Chain Analyst vs Inventory Controller Infographic

jobdiv.com

jobdiv.com