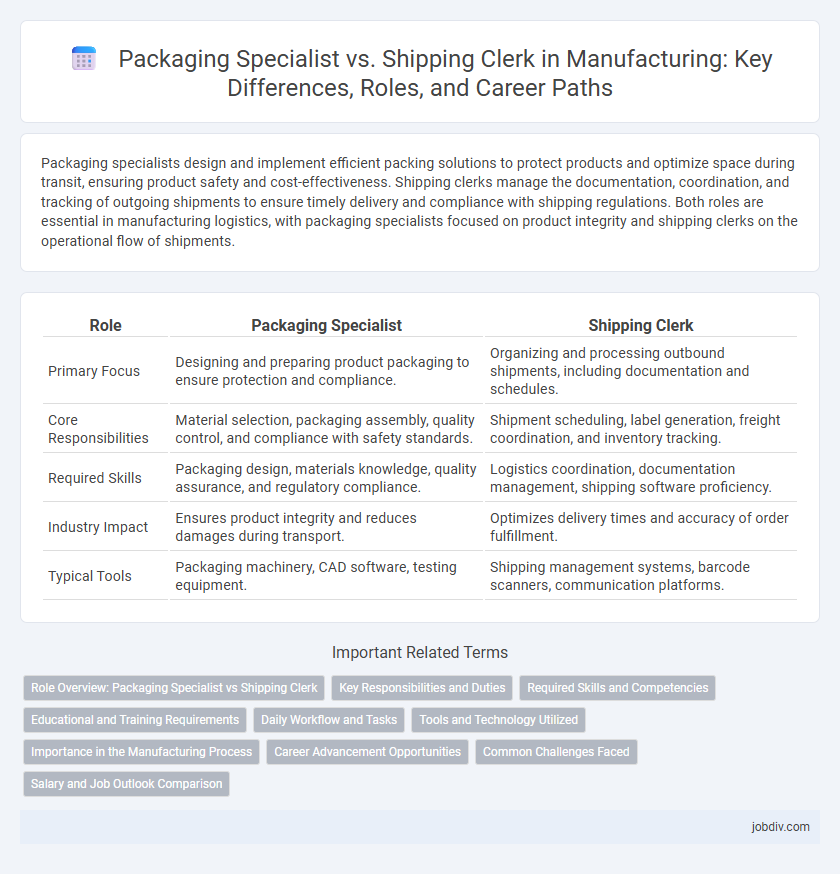

Packaging specialists design and implement efficient packing solutions to protect products and optimize space during transit, ensuring product safety and cost-effectiveness. Shipping clerks manage the documentation, coordination, and tracking of outgoing shipments to ensure timely delivery and compliance with shipping regulations. Both roles are essential in manufacturing logistics, with packaging specialists focused on product integrity and shipping clerks on the operational flow of shipments.

Table of Comparison

| Role | Packaging Specialist | Shipping Clerk |

|---|---|---|

| Primary Focus | Designing and preparing product packaging to ensure protection and compliance. | Organizing and processing outbound shipments, including documentation and schedules. |

| Core Responsibilities | Material selection, packaging assembly, quality control, and compliance with safety standards. | Shipment scheduling, label generation, freight coordination, and inventory tracking. |

| Required Skills | Packaging design, materials knowledge, quality assurance, and regulatory compliance. | Logistics coordination, documentation management, shipping software proficiency. |

| Industry Impact | Ensures product integrity and reduces damages during transport. | Optimizes delivery times and accuracy of order fulfillment. |

| Typical Tools | Packaging machinery, CAD software, testing equipment. | Shipping management systems, barcode scanners, communication platforms. |

Role Overview: Packaging Specialist vs Shipping Clerk

Packaging Specialists design and implement efficient packaging solutions to protect products during transit while optimizing materials for cost-effectiveness and sustainability. Shipping Clerks manage the logistics of outbound shipments, including preparing shipping documents, coordinating carriers, and ensuring timely delivery to customers. Both roles are essential for seamless supply chain operations, with Packaging Specialists focusing on product protection and material selection, and Shipping Clerks concentrating on shipment accuracy and documentation.

Key Responsibilities and Duties

A Packaging Specialist focuses on designing, testing, and implementing packaging solutions to protect products during manufacturing and transit, ensuring compliance with industry standards and sustainability goals. A Shipping Clerk handles the coordination of outgoing shipments, including preparing shipping documents, scheduling carriers, and tracking deliveries to guarantee timely and accurate order fulfillment. Both roles require strong attention to detail, but the Packaging Specialist emphasizes material selection and damage prevention, while the Shipping Clerk prioritizes logistics and documentation accuracy.

Required Skills and Competencies

Packaging Specialists require expertise in material science, quality control, and compliance with safety regulations to design and inspect packaging that protects products during transport. Shipping Clerks must excel in inventory management, documentation accuracy, and familiarity with logistics software to ensure timely and precise order fulfillment. Both roles demand strong organizational skills and attention to detail, but Packaging Specialists focus more on product protection, while Shipping Clerks emphasize efficient shipment processing.

Educational and Training Requirements

Packaging Specialists typically require a high school diploma with specialized training in packaging technology, materials science, or industrial design, often supplemented by certifications such as Certified Packaging Professional (CPP). Shipping Clerks generally need a high school diploma and on-the-job training focused on logistics, inventory management, and shipping software systems. Advanced roles in either position may demand knowledge of compliance regulations, supply chain principles, or proficiency in ERP systems to optimize packaging effectiveness and shipping accuracy.

Daily Workflow and Tasks

A Packaging Specialist focuses on designing, testing, and implementing effective packaging solutions to ensure product safety and compliance with industry standards, often collaborating with production teams and quality control. A Shipping Clerk manages order processing, prepares shipping documents, coordinates with carriers, and tracks outgoing shipments to ensure timely delivery. Both roles require attention to detail, but the Packaging Specialist emphasizes material selection and protection, while the Shipping Clerk concentrates on logistics and documentation accuracy.

Tools and Technology Utilized

Packaging Specialists utilize advanced packaging software, automated machinery, and quality control tools to design and optimize product packaging for durability and cost-efficiency. Shipping Clerks rely heavily on logistics management systems, barcode scanners, and inventory tracking software to ensure accurate shipment processing and delivery. Both roles integrate ERP systems but differ in their focus, with Packaging Specialists emphasizing product protection technology and Shipping Clerks prioritizing supply chain coordination tools.

Importance in the Manufacturing Process

Packaging Specialists ensure products are securely and efficiently packaged to meet quality standards, minimizing damage during transit and enhancing customer satisfaction. Shipping Clerks coordinate the accurate and timely dispatch of goods, managing logistics and documentation to maintain supply chain flow. Both roles are crucial in manufacturing, as proper packaging preserves product integrity while effective shipping ensures delivery accuracy and operational continuity.

Career Advancement Opportunities

Packaging Specialists benefit from expertise in material selection and design innovation, which can lead to career advancement into roles such as Packaging Engineer or Production Manager. Shipping Clerks develop skills in logistics coordination and supply chain management, creating pathways toward positions like Logistics Supervisor or Inventory Control Manager. Both careers offer distinct trajectories, with Packaging Specialists focusing on product protection and shipping Clerks emphasizing distribution efficiency.

Common Challenges Faced

Packaging Specialists and Shipping Clerks both encounter challenges related to managing inventory accuracy, ensuring product safety, and meeting tight delivery schedules. Packaging Specialists face difficulties with selecting appropriate materials and maintaining consistency in protective packaging, while Shipping Clerks struggle with coordinating logistics and handling customs documentation efficiently. Both roles require strong attention to detail and effective communication to prevent errors that could lead to delays or damaged goods.

Salary and Job Outlook Comparison

Packaging specialists in manufacturing earn an average annual salary ranging from $40,000 to $55,000, with job growth projected at 5% over the next decade, driven by increasing demand for efficient product packaging. Shipping clerks typically earn between $30,000 and $45,000 annually, facing a slower job outlook with a 2% growth rate due to automation and streamlined logistics processes. The higher salary and more favorable job outlook make packaging specialist roles more attractive for long-term career prospects within the manufacturing sector.

Packaging Specialist vs Shipping Clerk Infographic

jobdiv.com

jobdiv.com