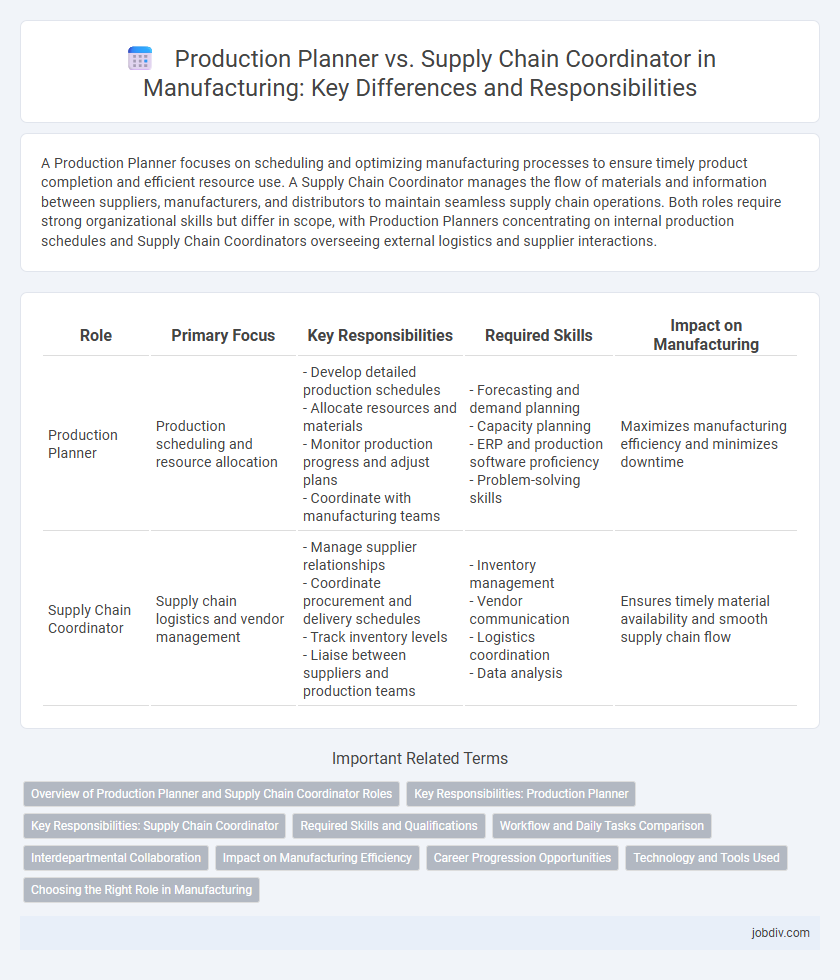

A Production Planner focuses on scheduling and optimizing manufacturing processes to ensure timely product completion and efficient resource use. A Supply Chain Coordinator manages the flow of materials and information between suppliers, manufacturers, and distributors to maintain seamless supply chain operations. Both roles require strong organizational skills but differ in scope, with Production Planners concentrating on internal production schedules and Supply Chain Coordinators overseeing external logistics and supplier interactions.

Table of Comparison

| Role | Primary Focus | Key Responsibilities | Required Skills | Impact on Manufacturing |

|---|---|---|---|---|

| Production Planner | Production scheduling and resource allocation |

- Develop detailed production schedules - Allocate resources and materials - Monitor production progress and adjust plans - Coordinate with manufacturing teams |

- Forecasting and demand planning - Capacity planning - ERP and production software proficiency - Problem-solving skills |

Maximizes manufacturing efficiency and minimizes downtime |

| Supply Chain Coordinator | Supply chain logistics and vendor management |

- Manage supplier relationships - Coordinate procurement and delivery schedules - Track inventory levels - Liaise between suppliers and production teams |

- Inventory management - Vendor communication - Logistics coordination - Data analysis |

Ensures timely material availability and smooth supply chain flow |

Overview of Production Planner and Supply Chain Coordinator Roles

Production Planners manage manufacturing schedules, ensuring materials, labor, and equipment align to meet production targets efficiently. Supply Chain Coordinators oversee the flow of goods and information from suppliers to customers, optimizing logistics and inventory management. Both roles are critical for seamless manufacturing operations, with planners focusing on in-house production processes and coordinators managing external supply chain activities.

Key Responsibilities: Production Planner

Production Planners are responsible for developing detailed production schedules that optimize resource allocation and meet customer demand forecasts. They coordinate with procurement, manufacturing, and logistics teams to ensure timely material availability and minimize production downtime. Monitoring inventory levels, analyzing workflow efficiency, and adjusting plans based on real-time data are critical to maintaining a continuous and cost-effective production process.

Key Responsibilities: Supply Chain Coordinator

A Supply Chain Coordinator manages the end-to-end supply chain process by coordinating procurement, inventory control, and logistics to ensure timely delivery of materials and products. Key responsibilities include monitoring supplier performance, maintaining accurate inventory records, and collaborating with vendors and internal departments to resolve supply chain disruptions. This role plays a critical part in optimizing supply chain efficiency, reducing costs, and supporting production schedules.

Required Skills and Qualifications

Production Planners require strong analytical abilities, proficiency in ERP systems, and expertise in demand forecasting to efficiently schedule manufacturing processes. Supply Chain Coordinators must possess excellent communication skills, knowledge of logistics management, and experience with inventory control to ensure smooth supply chain operations. Both roles demand attention to detail, problem-solving capabilities, and a solid understanding of production workflows and supply chain dynamics.

Workflow and Daily Tasks Comparison

Production planners focus on scheduling manufacturing processes, ensuring optimal resource allocation and timely completion of production runs. Supply chain coordinators manage the flow of materials, coordinate supplier communication, and monitor inventory to prevent bottlenecks. Workflow differences highlight that production planners emphasize internal operations and capacity planning, while supply chain coordinators prioritize external logistics and supplier relationship management.

Interdepartmental Collaboration

Production Planners and Supply Chain Coordinators both play critical roles in interdepartmental collaboration within manufacturing environments. Production Planners coordinate closely with engineering, procurement, and quality control teams to ensure manufacturing schedules meet demand forecasts and resource availability. Supply Chain Coordinators interface with logistics, suppliers, and warehouse departments to optimize materials flow and inventory levels, supporting seamless production continuity.

Impact on Manufacturing Efficiency

Production planners optimize manufacturing schedules by aligning resources, labor, and equipment to reduce downtime and meet output targets. Supply chain coordinators manage inbound materials and logistics, ensuring timely delivery of components to prevent production delays. Both roles directly influence manufacturing efficiency by synchronizing operations and minimizing bottlenecks in the production cycle.

Career Progression Opportunities

Production Planners often advance into roles such as Senior Production Manager or Operations Manager due to their expertise in scheduling, resource allocation, and workflow optimization. Supply Chain Coordinators may progress to Supply Chain Analyst or Logistics Manager positions by leveraging their skills in inventory management, supplier relations, and distribution processes. Career progression in manufacturing favors professionals who develop strong analytical, coordination, and problem-solving abilities within production and supply chain domains.

Technology and Tools Used

Production Planners utilize advanced planning software such as SAP PP and Oracle NetSuite to optimize manufacturing schedules and resource allocation, ensuring efficient workflow and minimal downtime. Supply Chain Coordinators rely on tools like SAP SCM and EDI systems to manage supplier relationships, track shipments in real-time, and coordinate inventory levels across multiple locations. Both roles increasingly leverage AI-driven analytics platforms to enhance demand forecasting and operational decision-making.

Choosing the Right Role in Manufacturing

Choosing the right role in manufacturing between a Production Planner and a Supply Chain Coordinator depends on your focus and skill set. Production Planners optimize manufacturing schedules, manage inventory levels, and ensure timely product completion, while Supply Chain Coordinators oversee supplier relationships, logistics, and materials flow to support production. Understanding the specific demands of your manufacturing environment helps align responsibilities with organizational goals and improves overall operational efficiency.

Production Planner vs Supply Chain Coordinator Infographic

jobdiv.com

jobdiv.com