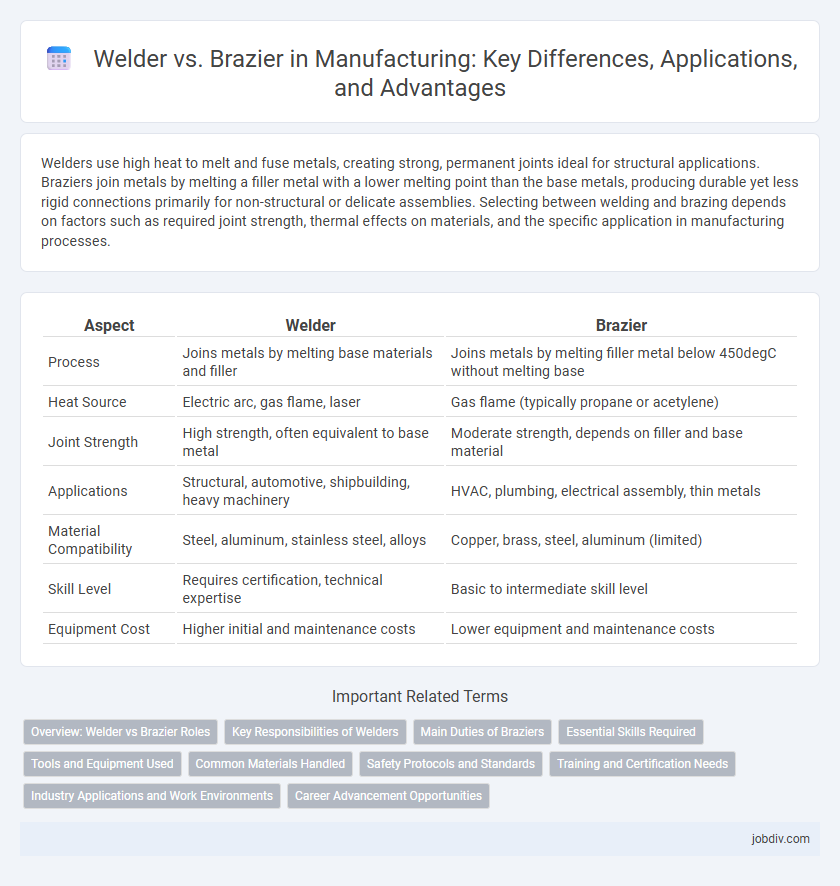

Welders use high heat to melt and fuse metals, creating strong, permanent joints ideal for structural applications. Braziers join metals by melting a filler metal with a lower melting point than the base metals, producing durable yet less rigid connections primarily for non-structural or delicate assemblies. Selecting between welding and brazing depends on factors such as required joint strength, thermal effects on materials, and the specific application in manufacturing processes.

Table of Comparison

| Aspect | Welder | Brazier |

|---|---|---|

| Process | Joins metals by melting base materials and filler | Joins metals by melting filler metal below 450degC without melting base |

| Heat Source | Electric arc, gas flame, laser | Gas flame (typically propane or acetylene) |

| Joint Strength | High strength, often equivalent to base metal | Moderate strength, depends on filler and base material |

| Applications | Structural, automotive, shipbuilding, heavy machinery | HVAC, plumbing, electrical assembly, thin metals |

| Material Compatibility | Steel, aluminum, stainless steel, alloys | Copper, brass, steel, aluminum (limited) |

| Skill Level | Requires certification, technical expertise | Basic to intermediate skill level |

| Equipment Cost | Higher initial and maintenance costs | Lower equipment and maintenance costs |

Overview: Welder vs Brazier Roles

Welders use high heat to fuse metals together by melting the base materials, creating a strong, permanent joint essential in heavy industries like construction and automotive manufacturing. Braziers join metals using a filler metal with a lower melting point than the workpieces, producing a bond without melting the base metals, commonly applied in plumbing and HVAC systems. Both roles require specialized skills and knowledge of metal properties but differ fundamentally in technique, joint strength, and typical application scenarios.

Key Responsibilities of Welders

Welders are responsible for joining metal parts using high-temperature fusion processes like arc welding, MIG, and TIG welding to ensure strong, durable bonds. They interpret blueprints, select appropriate materials, and operate welding equipment with precision to meet safety and quality standards. Welders also perform inspections and maintenance on welding tools while ensuring structural integrity in manufacturing assemblies.

Main Duties of Braziers

Braziers specialize in joining metal components using a filler metal with a lower melting point than the base metals, primarily through the brazing process which involves heating the joint area but not melting the base metals. Their main duties include preparing surfaces by cleaning and positioning parts accurately, selecting appropriate filler metals and fluxes, and applying heat using torches or furnaces to create strong, leak-proof joints. Braziers often inspect finished joints for quality and may perform repairs or adjustments to ensure compliance with manufacturing standards and specifications.

Essential Skills Required

Welders require proficiency in understanding welding techniques such as MIG, TIG, and arc welding, along with skills in reading blueprints and operating welding equipment safely. Braziers must master precise temperature control, knowledge of metallurgy, and the ability to apply filler metals without melting base materials. Both roles demand strong hand-eye coordination, attention to detail, and adherence to safety protocols in manufacturing environments.

Tools and Equipment Used

Welders primarily use arc welding machines, electrodes, and protective gear such as helmets and gloves to fuse metals by melting their edges. Braziers utilize torches fueled by propane or acetylene, along with filler metals like brass or copper alloys, to join metals without melting the base materials. Both rely on specialized tools tailored to the specific joining technique, influencing the strength and application of the final product.

Common Materials Handled

Welders typically work with metals such as steel, stainless steel, aluminum, and cast iron, using high temperatures to fuse parts together. Braziers commonly handle metals like copper, brass, and bronze, joining them by melting a filler metal with a lower melting point than the base materials. Both processes require precise temperature control and are essential for fabricating durable metal structures in manufacturing industries.

Safety Protocols and Standards

Welder safety protocols emphasize protective gear including flame-resistant clothing, welding helmets with auto-darkening filters, and gloves to prevent burns and eye damage. Brazier standards focus on proper ventilation to avoid inhaling toxic fumes, use of heat-resistant gloves, and maintaining clean work surfaces to prevent fire hazards. Both professions require adherence to Occupational Safety and Health Administration (OSHA) regulations and regular equipment inspections to ensure workplace safety.

Training and Certification Needs

Welders require formal training and certification such as AWS (American Welding Society) or ASME (American Society of Mechanical Engineers) credentials, ensuring proficiency in various welding techniques and safety protocols. Brazers need specific brazing certifications, like the AWS Brazing Certificate, focused on joint design, heat control, and filler metals, which differ from welding requirements. Both roles demand ongoing education to stay current with industry standards and maintain competency in fabrication and repair applications.

Industry Applications and Work Environments

Welders are essential in heavy industries such as automotive manufacturing, construction, and shipbuilding where strong, high-temperature metal fusion is required to create structural joints. Braziers, on the other hand, are primarily used in HVAC, plumbing, and electronics manufacturing sectors for joining delicate components using lower-temperature filler metals, preserving base materials. Work environments for welders typically involve outdoor or industrial sites with high heat and potential safety hazards, while braziers often operate in controlled, indoor settings requiring precision and quality control.

Career Advancement Opportunities

Welders typically have broader career advancement opportunities due to their ability to work with various metals and complex joining techniques, making them suitable for industries like construction, aerospace, and automotive manufacturing. Brazier careers often focus on specialized roles in decorative metalwork or HVAC systems, which may limit diversification but provide niche expertise. Certifications such as AWS for welders significantly enhance job prospects and salary potential compared to brazers, who rely on mastery of techniques like capillary action and flux application.

Welder vs Brazier Infographic

jobdiv.com

jobdiv.com