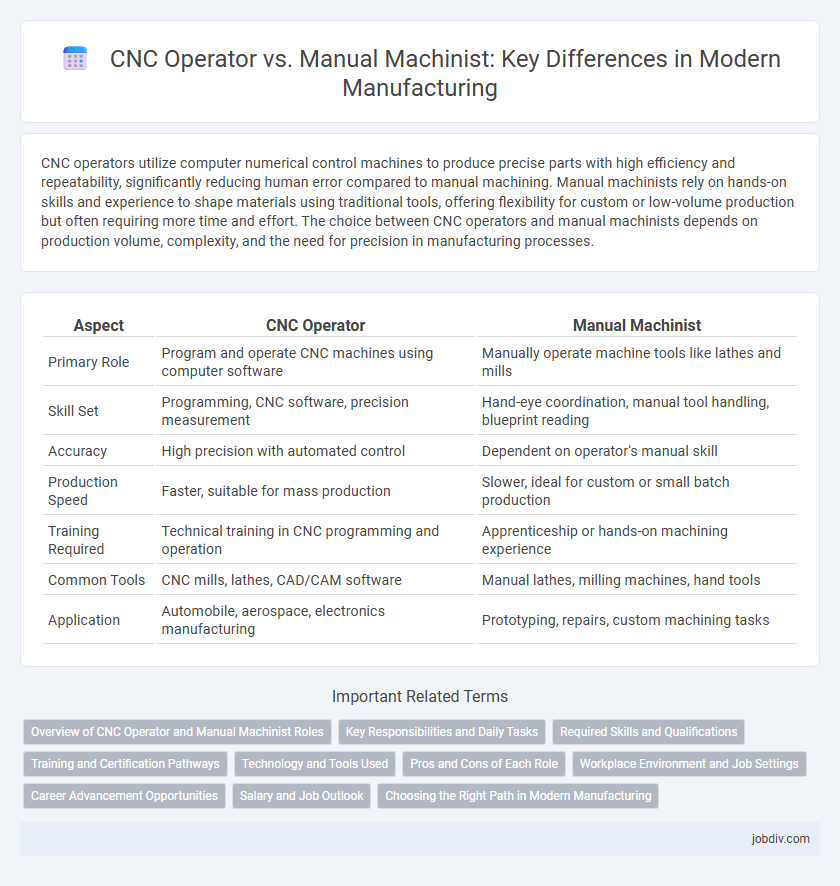

CNC operators utilize computer numerical control machines to produce precise parts with high efficiency and repeatability, significantly reducing human error compared to manual machining. Manual machinists rely on hands-on skills and experience to shape materials using traditional tools, offering flexibility for custom or low-volume production but often requiring more time and effort. The choice between CNC operators and manual machinists depends on production volume, complexity, and the need for precision in manufacturing processes.

Table of Comparison

| Aspect | CNC Operator | Manual Machinist |

|---|---|---|

| Primary Role | Program and operate CNC machines using computer software | Manually operate machine tools like lathes and mills |

| Skill Set | Programming, CNC software, precision measurement | Hand-eye coordination, manual tool handling, blueprint reading |

| Accuracy | High precision with automated control | Dependent on operator's manual skill |

| Production Speed | Faster, suitable for mass production | Slower, ideal for custom or small batch production |

| Training Required | Technical training in CNC programming and operation | Apprenticeship or hands-on machining experience |

| Common Tools | CNC mills, lathes, CAD/CAM software | Manual lathes, milling machines, hand tools |

| Application | Automobile, aerospace, electronics manufacturing | Prototyping, repairs, custom machining tasks |

Overview of CNC Operator and Manual Machinist Roles

CNC Operators program and control computer numerical control machines to produce precision parts with automated accuracy, optimizing production efficiency in manufacturing. Manual Machinists operate traditional machine tools such as lathes, mills, and grinders, relying on skill and experience to shape metal components. Both roles require understanding of materials and tolerances, but CNC Operators emphasize programming and machine setup, while Manual Machinists focus on hands-on craftsmanship and manual adjustments.

Key Responsibilities and Daily Tasks

CNC Operators manage programmable computer numerical control machines to produce precision parts, ensuring accuracy through software input and machine calibration, while Manual Machinists rely on hand tools and manual controls to shape and finish metal components. CNC Operators typically handle tasks like setting up machines, monitoring automated processes, and performing quality checks using measuring instruments, whereas Manual Machinists engage in cutting, grinding, and adjusting tools by hand for custom fabrication and repairs. Both roles require strong technical skills and attention to detail, but CNC operations emphasize programming and machine maintenance, while manual machining prioritizes craftsmanship and hands-on adjustments.

Required Skills and Qualifications

CNC operators require proficiency in computer-aided design (CAD) software, G-code programming, and precision measurement tools, alongside strong technical troubleshooting abilities. Manual machinists must excel in hand-eye coordination, manual machine tool operation, blueprint reading, and skilled use of hand tools for metal shaping and finishing. Both roles demand a solid understanding of materials science, mechanical principles, and adherence to safety protocols for manufacturing processes.

Training and Certification Pathways

CNC operators typically undergo specialized training programs that emphasize computer-aided design (CAD), computer-aided manufacturing (CAM), and G-code programming, often culminating in certifications such as the National Institute for Metalworking Skills (NIMS) CNC Operator credential. Manual machinists usually follow an apprenticeship model or vocational training that prioritizes hands-on skills in manual machine tools, supplemented by certifications like the NCCER (National Center for Construction Education and Research) Mechanical Fabrication certification. Both pathways demand rigorous safety training and continuous skill development, but CNC operator programs often incorporate more digital literacy and programming competencies.

Technology and Tools Used

CNC operators utilize computer numerical control machines, employing advanced software and automated tools to achieve precise, repeatable cuts and shapes in manufacturing. Manual machinists rely on traditional hand-cranked lathes, mills, and other mechanical tools, requiring significant skill and experience to maintain accuracy. CNC technology integrates CAD/CAM software, enabling faster production times and complex designs, whereas manual machining depends heavily on operator expertise and manual adjustments.

Pros and Cons of Each Role

CNC operators excel in precision and repeatability, improving efficiency with automated programming, but require technical skills and face high initial training costs. Manual machinists offer flexibility for complex, one-off parts and can quickly adjust to design changes, though their work is more time-consuming and prone to human error. Balancing these roles depends on production volume, complexity, and the need for scalability in manufacturing processes.

Workplace Environment and Job Settings

CNC operators typically work in controlled, climate-regulated factory settings with automated machinery, reducing physical strain and exposure to hazardous materials. Manual machinists often operate in more variable environments requiring hands-on adjustments and direct interaction with traditional machine tools, increasing exposure to noise and repetitive motions. Both roles demand stringent safety protocols but differ significantly in ergonomic demands and technological integration.

Career Advancement Opportunities

CNC operators benefit from increased career advancement opportunities due to the growing demand for automated precision in manufacturing, often progressing to programming or supervisory roles. Manual machinists, while skilled in traditional techniques, face limited advancement without cross-training in CNC technologies. Mastery of computer numerical control systems significantly enhances employability and promotion potential within the evolving manufacturing industry.

Salary and Job Outlook

CNC operators typically earn higher salaries than manual machinists, with average annual wages ranging from $45,000 to $60,000 compared to $35,000 to $50,000 for manual machinists. The job outlook for CNC operators is more favorable, driven by increased automation and demand for precision manufacturing in industries such as aerospace and automotive. Manual machinists face slower job growth due to the rising adoption of CNC technology, emphasizing the need for upskilling in CNC programming and operation.

Choosing the Right Path in Modern Manufacturing

CNC Operators leverage computer numerical control technology for precision, efficiency, and repeatability in modern manufacturing, making them ideal for complex, high-volume production environments. Manual Machinists excel in craftsmanship and adaptability, performing custom or low-volume tasks that require hands-on expertise and problem-solving skills. Selecting the right career path depends on aligning your strengths with industry demands, as CNC machining suits those proficient with digital systems, while manual machining favors skilled artisans with mechanical intuition.

CNC Operator vs Manual Machinist Infographic

jobdiv.com

jobdiv.com