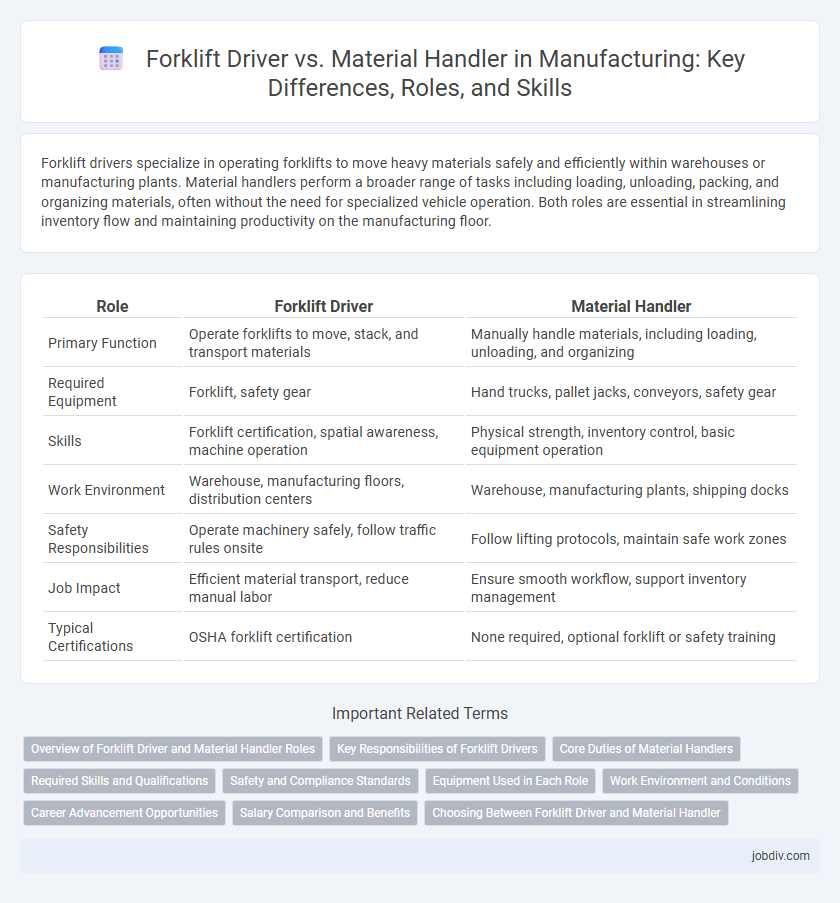

Forklift drivers specialize in operating forklifts to move heavy materials safely and efficiently within warehouses or manufacturing plants. Material handlers perform a broader range of tasks including loading, unloading, packing, and organizing materials, often without the need for specialized vehicle operation. Both roles are essential in streamlining inventory flow and maintaining productivity on the manufacturing floor.

Table of Comparison

| Role | Forklift Driver | Material Handler |

|---|---|---|

| Primary Function | Operate forklifts to move, stack, and transport materials | Manually handle materials, including loading, unloading, and organizing |

| Required Equipment | Forklift, safety gear | Hand trucks, pallet jacks, conveyors, safety gear |

| Skills | Forklift certification, spatial awareness, machine operation | Physical strength, inventory control, basic equipment operation |

| Work Environment | Warehouse, manufacturing floors, distribution centers | Warehouse, manufacturing plants, shipping docks |

| Safety Responsibilities | Operate machinery safely, follow traffic rules onsite | Follow lifting protocols, maintain safe work zones |

| Job Impact | Efficient material transport, reduce manual labor | Ensure smooth workflow, support inventory management |

| Typical Certifications | OSHA forklift certification | None required, optional forklift or safety training |

Overview of Forklift Driver and Material Handler Roles

Forklift drivers operate powered industrial trucks to move, lift, and stack materials in warehouses or manufacturing sites, ensuring efficient inventory management and safe handling of goods. Material handlers perform a broader range of tasks including loading, unloading, and transporting materials manually or with equipment, supporting production lines and supply chain processes. Both roles are critical in manufacturing environments for maintaining workflow continuity and optimizing material movement.

Key Responsibilities of Forklift Drivers

Forklift drivers are primarily responsible for operating powered industrial trucks to transport heavy materials within manufacturing facilities, ensuring safe loading and unloading of goods. They conduct routine inspections of forklifts, maintain equipment safety, and comply with OSHA standards to prevent workplace accidents. Their expertise in maneuvering forklifts in tight spaces optimizes material flow and supports efficient production processes.

Core Duties of Material Handlers

Material handlers primarily focus on the efficient movement, storage, and control of materials within manufacturing facilities to support production workflows. Their core duties include loading and unloading raw materials, inspecting inventory for accuracy, and organizing products for shipment or storage using equipment like pallet jacks and forklifts. Unlike forklift drivers who specialize in operating forklifts, material handlers often engage in diverse tasks such as inventory management, packaging, and quality checks to maintain seamless supply chain operations.

Required Skills and Qualifications

Forklift drivers require specialized certification, strong spatial awareness, and excellent hand-eye coordination to safely operate heavy machinery in manufacturing settings. Material handlers need physical stamina, inventory management knowledge, and proficiency in using warehouse management systems to efficiently move and organize materials. Both roles demand attention to safety protocols, teamwork skills, and the ability to follow detailed operational procedures.

Safety and Compliance Standards

Forklift drivers must adhere to strict OSHA regulations, including certification, regular equipment inspections, and wearing personal protective equipment to ensure workplace safety. Material handlers follow safety protocols involving manual material lifting techniques, ergonomic practices, and hazard identification to prevent injuries. Both roles require comprehensive training programs to maintain compliance with industry standards and reduce accident risks in manufacturing environments.

Equipment Used in Each Role

Forklift drivers primarily operate powered industrial trucks such as forklifts, pallet jacks, and stackers designed to lift and transport heavy loads efficiently within warehouses and manufacturing plants. Material handlers use a broader range of equipment, including hand trucks, conveyor belts, hoists, and automated guided vehicles (AGVs) to manage inventory, move materials, and assist in production flow. The equipment choice directly impacts operational speed, safety protocols, and task specialization across manufacturing environments.

Work Environment and Conditions

Forklift drivers operate in environments requiring tight maneuvering of heavy loads, often in warehouses, factories, or construction sites with varying temperature and noise levels. Material handlers typically work in broader settings, including shipping docks and production floors, managing inventory and moving goods with less emphasis on vehicle operation. Both roles demand adherence to safety protocols but differ in physical exertion and equipment usage within industrial and manufacturing contexts.

Career Advancement Opportunities

Forklift drivers often have specialized skills that can lead to advancement into logistics supervisor or warehouse manager roles within manufacturing environments. Material handlers typically gain broad operational experience, allowing progression into supply chain coordinator or inventory control positions. Both career paths offer opportunities for certifications and training that enhance professional growth and salary potential.

Salary Comparison and Benefits

Forklift drivers in manufacturing typically earn higher salaries than material handlers, with average annual wages ranging from $35,000 to $45,000 compared to $28,000 to $38,000 for material handlers. Forklift drivers often receive specialized benefits such as certification reimbursements and safety bonuses, enhancing their overall compensation package. Material handlers benefit from broader job flexibility and may access health insurance and retirement plans, but their pay scale and perks are generally less lucrative than those for forklift operators.

Choosing Between Forklift Driver and Material Handler

Choosing between a forklift driver and a material handler depends largely on the specific operational needs and safety requirements within a manufacturing facility. Forklift drivers specialize in operating powered industrial trucks to move heavy loads efficiently, while material handlers manage the broader flow of materials, including manual lifting, sorting, and inventory control. Evaluating factors such as the volume of heavy goods, workspace layout, and required certifications is essential for optimizing workflow and minimizing workplace hazards in manufacturing environments.

Forklift Driver vs Material Handler Infographic

jobdiv.com

jobdiv.com