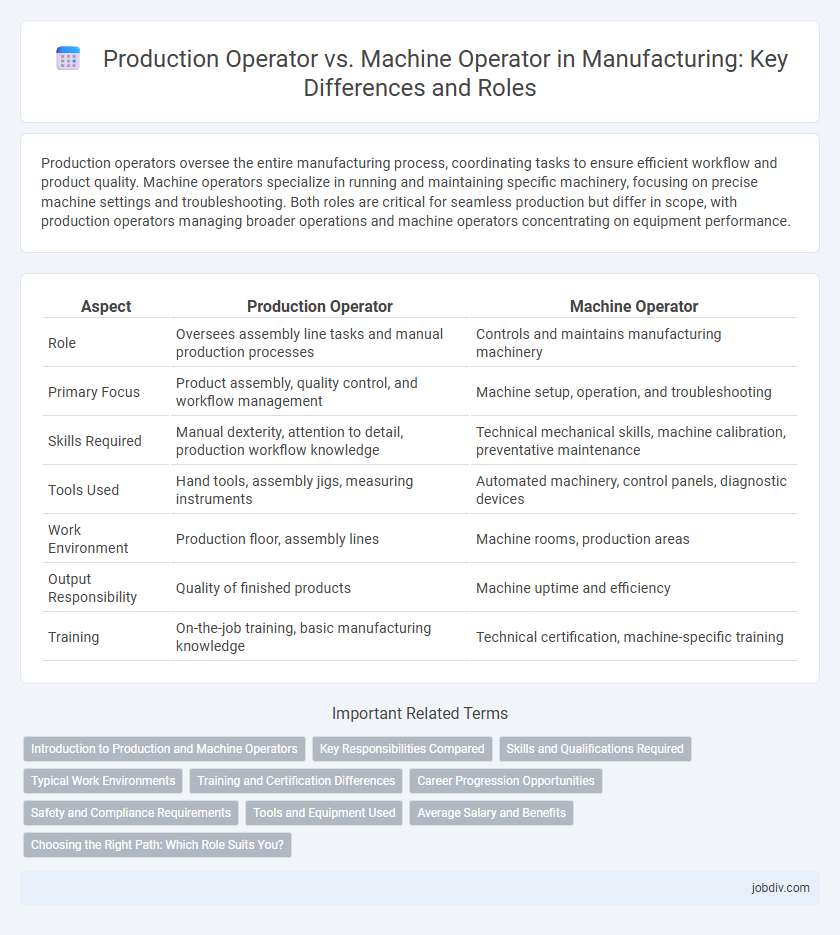

Production operators oversee the entire manufacturing process, coordinating tasks to ensure efficient workflow and product quality. Machine operators specialize in running and maintaining specific machinery, focusing on precise machine settings and troubleshooting. Both roles are critical for seamless production but differ in scope, with production operators managing broader operations and machine operators concentrating on equipment performance.

Table of Comparison

| Aspect | Production Operator | Machine Operator |

|---|---|---|

| Role | Oversees assembly line tasks and manual production processes | Controls and maintains manufacturing machinery |

| Primary Focus | Product assembly, quality control, and workflow management | Machine setup, operation, and troubleshooting |

| Skills Required | Manual dexterity, attention to detail, production workflow knowledge | Technical mechanical skills, machine calibration, preventative maintenance |

| Tools Used | Hand tools, assembly jigs, measuring instruments | Automated machinery, control panels, diagnostic devices |

| Work Environment | Production floor, assembly lines | Machine rooms, production areas |

| Output Responsibility | Quality of finished products | Machine uptime and efficiency |

| Training | On-the-job training, basic manufacturing knowledge | Technical certification, machine-specific training |

Introduction to Production and Machine Operators

Production operators oversee the entire manufacturing process, ensuring smooth workflow and quality control from start to finish. Machine operators specialize in operating and maintaining specific machinery, focusing on precision and equipment safety. Both roles are essential for efficient production lines and require technical skills tailored to their responsibilities.

Key Responsibilities Compared

Production Operators oversee the entire manufacturing process, ensuring raw materials are properly assembled into finished goods while maintaining quality standards and adhering to safety protocols. Machine Operators specialize in operating, maintaining, and troubleshooting specific machinery, ensuring optimal machine performance and minimizing downtime. Both roles require attention to detail and adherence to production schedules, but Production Operators have broader responsibilities encompassing workflow management and product inspection.

Skills and Qualifications Required

Production Operators require strong mechanical aptitude, attention to detail, and the ability to perform repetitive tasks efficiently, often needing a high school diploma or equivalent and basic training in production processes. Machine Operators must possess specialized technical skills to operate, maintain, and troubleshoot complex machinery, typically requiring vocational training or certification in equipment handling and safety protocols. Both roles demand adherence to safety standards, problem-solving abilities, and teamwork within fast-paced manufacturing environments.

Typical Work Environments

Production operators typically work in assembly lines, manufacturing plants, and warehouses where they handle various stages of product assembly and quality control. Machine operators primarily operate and monitor specific machinery in environments such as fabrication shops, injection molding facilities, and CNC machining centers. Both roles require adherence to safety protocols and often involve standing for long periods in temperature-controlled or noise-intensive settings.

Training and Certification Differences

Production operators require comprehensive training on assembly processes, quality control, and safety protocols to handle various production stages efficiently. Machine operators undergo specialized certification focused on machine setup, operation, maintenance, and troubleshooting to ensure precise equipment handling. Training for production operators tends to be broader, while machine operators receive in-depth technical instruction specific to machinery operation and compliance standards.

Career Progression Opportunities

Production Operators often have broader responsibilities overseeing the entire manufacturing process, allowing them to develop skills in quality control, inventory management, and team coordination, which can lead to supervisory or process improvement roles. Machine Operators typically specialize in the operation and maintenance of specific equipment, gaining technical expertise that can advance into technical support, machine maintenance leadership, or specialized machining careers. Career progression for Production Operators tends to emphasize leadership and process optimization, while Machine Operators focus on technical mastery and equipment specialization within manufacturing.

Safety and Compliance Requirements

Production operators and machine operators both play crucial roles in manufacturing, but safety and compliance requirements differ significantly between the two. Machine operators must strictly adhere to equipment-specific safety protocols, including lockout/tagout procedures and personal protective equipment (PPE) standards, to prevent accidents caused by machinery malfunctions or improper handling. Production operators are responsible for following broader workplace safety regulations and quality control measures to maintain compliance with OSHA standards and ensure a safe production environment.

Tools and Equipment Used

Production Operators manage a variety of hand tools, assembly equipment, and inspection devices to ensure product quality and assembly accuracy. Machine Operators specialize in operating, adjusting, and maintaining large industrial machinery such as CNC machines, presses, and automated conveyor systems. Both roles require proficiency with safety gear like gloves and protective eyewear, but Machine Operators often engage more with computerized control panels and diagnostic software.

Average Salary and Benefits

Production operators typically earn an average salary ranging from $30,000 to $45,000 annually, with benefits including health insurance, paid time off, and retirement plans. Machine operators often have a slightly higher average salary, between $35,000 and $50,000 per year, reflecting specialized skills in handling complex machinery, and receive similar benefits such as dental coverage and tuition assistance. Both roles may offer overtime pay and opportunities for advancement, but machine operators usually benefit from higher wage premiums due to technical expertise.

Choosing the Right Path: Which Role Suits You?

Production Operators oversee the entire manufacturing process, ensuring that products meet quality standards and deadlines, while Machine Operators specialize in operating and maintaining specific machinery. Choosing the right path depends on your preference for hands-on equipment management versus broader production oversight. Skills in mechanical aptitude, attention to detail, and teamwork are crucial for both roles in a manufacturing environment.

Production Operator vs Machine Operator Infographic

jobdiv.com

jobdiv.com