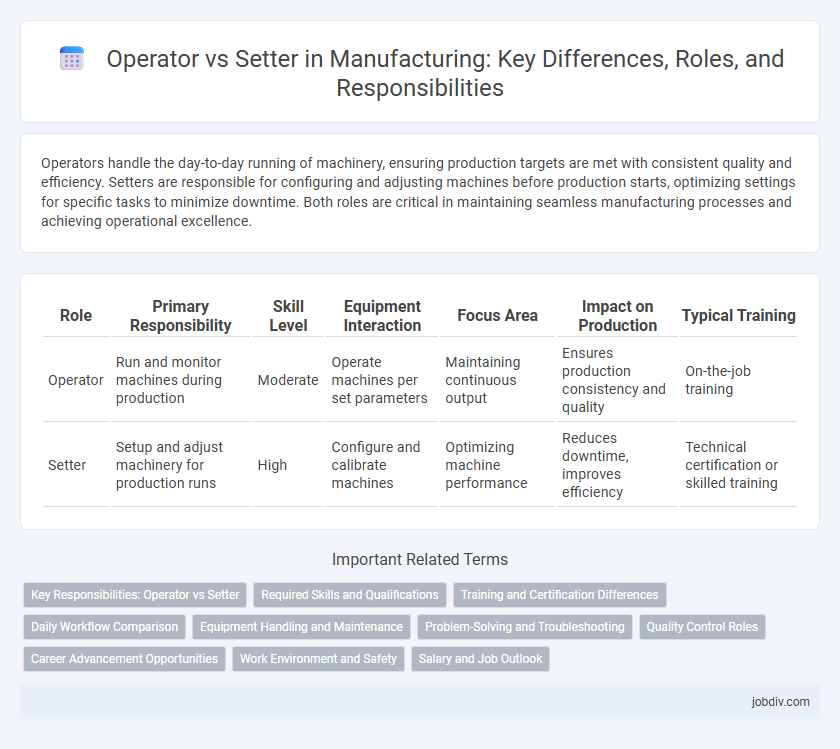

Operators handle the day-to-day running of machinery, ensuring production targets are met with consistent quality and efficiency. Setters are responsible for configuring and adjusting machines before production starts, optimizing settings for specific tasks to minimize downtime. Both roles are critical in maintaining seamless manufacturing processes and achieving operational excellence.

Table of Comparison

| Role | Primary Responsibility | Skill Level | Equipment Interaction | Focus Area | Impact on Production | Typical Training |

|---|---|---|---|---|---|---|

| Operator | Run and monitor machines during production | Moderate | Operate machines per set parameters | Maintaining continuous output | Ensures production consistency and quality | On-the-job training |

| Setter | Setup and adjust machinery for production runs | High | Configure and calibrate machines | Optimizing machine performance | Reduces downtime, improves efficiency | Technical certification or skilled training |

Key Responsibilities: Operator vs Setter

Operators primarily handle the operation and monitoring of machinery to ensure efficient production flow and quality control, while Setters focus on machine setup, adjustment, and maintenance to prepare equipment for specific manufacturing tasks. Operators execute production runs, troubleshoot machine issues during operation, and maintain production logs, whereas Setters perform precision calibration, change tooling, and verify machine readiness before production begins. Both roles require technical expertise, but Setters emphasize machine preparation and configuration, and Operators emphasize continuous process management and output consistency.

Required Skills and Qualifications

Operators require technical proficiency in machinery operation, quality control, and safety standards, emphasizing hands-on experience and problem-solving skills. Setters need advanced knowledge of equipment setup, calibration, and precision measurement tools, often holding certifications in mechanical or electrical engineering fields. Both roles demand attention to detail, adherence to production protocols, and strong communication abilities for effective teamwork in manufacturing environments.

Training and Certification Differences

Operators typically undergo basic training focused on machine operation and safety protocols, enabling them to run equipment efficiently. Setters receive more advanced, specialized training in machine setup, calibration, and troubleshooting, often requiring certification to ensure precision in production processes. Certification programs for setters emphasize technical skills and quality standards, reflecting their critical role in minimizing downtime and maintaining product consistency.

Daily Workflow Comparison

Operators primarily focus on running machines and monitoring production output to ensure efficiency and quality standards, while Setters handle the preparation and adjustment of equipment for specific jobs or product runs. Daily workflows for Operators involve continuous machine operation with real-time troubleshooting, whereas Setters concentrate on calibration, setup verification, and changeover processes before production begins. Both roles require collaboration to minimize downtime and maintain seamless manufacturing operations.

Equipment Handling and Maintenance

Operators are responsible for running machinery efficiently and monitoring equipment performance during production, ensuring consistent output quality. Setters specialize in configuring and adjusting machines before production runs, calibrating tools, and performing routine maintenance to prevent breakdowns. Both roles require thorough knowledge of equipment handling protocols and maintenance schedules to minimize downtime and optimize manufacturing processes.

Problem-Solving and Troubleshooting

Operators primarily focus on executing production tasks and following standard procedures, while Setters possess specialized skills in configuring and adjusting machinery to optimize performance. Setters are more adept at diagnosing equipment malfunctions and implementing technical solutions, making them essential for troubleshooting complex mechanical issues. Effective collaboration between operators and setters enhances problem-solving efficiency, reducing downtime and improving overall manufacturing productivity.

Quality Control Roles

Operators ensure consistent product quality by monitoring machinery and performing routine inspections during production runs. Setters focus on machine setup and calibration, adjusting equipment parameters to meet predefined specifications and minimize defects. Both roles collaborate closely with quality control teams to detect deviations and maintain manufacturing standards.

Career Advancement Opportunities

Operators in manufacturing focus on running machinery and often gain hands-on experience that can lead to advanced technical roles or supervisory positions. Setters specialize in configuring and adjusting equipment, developing expertise that paves the way for careers in machine programming, process optimization, or maintenance engineering. Both roles offer distinct pathways, with operators advancing through operational proficiency and setters progressing via technical specialization.

Work Environment and Safety

Operators work directly with machinery on the factory floor, requiring vigilant adherence to safety protocols to prevent accidents and ensure smooth production. Setters focus on preparing and adjusting equipment before operation, often working closely with technical manuals and precision tools in a controlled environment that demands careful attention to detail. Both roles necessitate comprehensive safety training, but the operator's environment involves real-time machine interaction, increasing exposure to physical hazards.

Salary and Job Outlook

Operators in manufacturing typically earn an average salary ranging from $35,000 to $50,000 annually, with steady demand driven by routine production tasks. Setters, who require specialized skills to configure and calibrate machinery, command higher salaries often between $45,000 and $65,000 per year, reflecting their technical expertise. The job outlook for setters is projected to grow faster than operators due to increasing automation and the need for skilled machine setup professionals.

Operator vs Setter Infographic

jobdiv.com

jobdiv.com