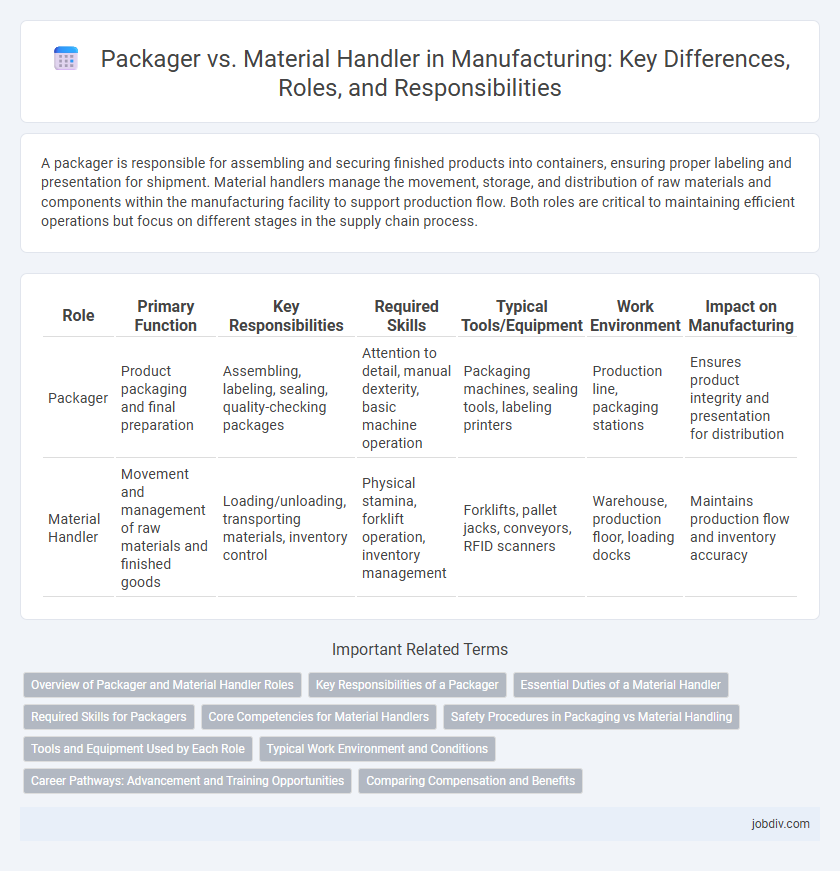

A packager is responsible for assembling and securing finished products into containers, ensuring proper labeling and presentation for shipment. Material handlers manage the movement, storage, and distribution of raw materials and components within the manufacturing facility to support production flow. Both roles are critical to maintaining efficient operations but focus on different stages in the supply chain process.

Table of Comparison

| Role | Primary Function | Key Responsibilities | Required Skills | Typical Tools/Equipment | Work Environment | Impact on Manufacturing |

|---|---|---|---|---|---|---|

| Packager | Product packaging and final preparation | Assembling, labeling, sealing, quality-checking packages | Attention to detail, manual dexterity, basic machine operation | Packaging machines, sealing tools, labeling printers | Production line, packaging stations | Ensures product integrity and presentation for distribution |

| Material Handler | Movement and management of raw materials and finished goods | Loading/unloading, transporting materials, inventory control | Physical stamina, forklift operation, inventory management | Forklifts, pallet jacks, conveyors, RFID scanners | Warehouse, production floor, loading docks | Maintains production flow and inventory accuracy |

Overview of Packager and Material Handler Roles

Packagers are responsible for assembling, wrapping, and labeling finished products to ensure they are ready for shipment, focusing on accuracy and compliance with packaging standards. Material Handlers manage the movement, storage, and inventory of raw materials and components within manufacturing facilities, optimizing workflow and minimizing delays. Both roles are critical for maintaining efficient production lines and ensuring timely delivery of goods.

Key Responsibilities of a Packager

Packagers are responsible for assembling, labeling, and securing products for shipment, ensuring packaging meets quality standards and industry regulations. They verify product quantities, inspect items for defects, and maintain accurate documentation for inventory control. Their role emphasizes efficient material handling within packaging lines to optimize production flow and reduce damage during transit.

Essential Duties of a Material Handler

Material handlers in manufacturing are responsible for receiving, storing, and distributing materials and products within the facility, ensuring a steady production flow. They operate forklifts and conveyor systems to transport raw materials and finished goods, maintain accurate inventory records, and perform quality inspections. Unlike packagers who primarily focus on assembling, wrapping, and labeling products for shipment, material handlers coordinate logistics and inventory control to support manufacturing operations efficiently.

Required Skills for Packagers

Packagers require strong attention to detail, manual dexterity, and the ability to follow precise instructions to ensure products are securely and correctly packed. Skills in operating packing machinery, understanding packaging materials, and maintaining safety standards are essential. Effective communication and teamwork also help packagers coordinate with material handlers and other manufacturing staff for streamlined operations.

Core Competencies for Material Handlers

Material Handlers excel in inventory control, efficient material movement, and equipment operation, ensuring seamless production flow and minimizing downtime. Their core competencies include forklift operation, order picking, and adherence to safety regulations, which support supply chain efficiency in manufacturing environments. Unlike packagers who focus on product wrapping and labeling, material handlers emphasize logistics coordination and warehouse organization to optimize material availability.

Safety Procedures in Packaging vs Material Handling

Safety procedures in packaging emphasize the proper use of personal protective equipment (PPE), safe machine operation, and careful handling of hazardous materials to prevent injuries. Material handlers must follow ergonomic lifting techniques, use mechanical aids like forklifts correctly, and adhere to workplace safety protocols to minimize risks associated with heavy load transportation. Both roles require rigorous training in hazard identification and emergency response to ensure compliance with Occupational Safety and Health Administration (OSHA) standards.

Tools and Equipment Used by Each Role

Packagers primarily use automated wrapping machines, sealing tools, and labeling equipment to prepare products for shipment efficiently. Material handlers rely on forklifts, pallet jacks, conveyor belts, and inventory management software to move, store, and track raw materials and finished goods within the manufacturing facility. Both roles utilize RFID scanners and barcode readers to ensure accuracy in product identification and inventory control.

Typical Work Environment and Conditions

Packagers typically work in controlled environments such as warehouses, production lines, and packaging facilities where temperature and cleanliness are regulated to maintain product quality. Material handlers operate in a wider range of settings including warehouses, loading docks, and outdoor storage areas, often facing varying weather conditions and heavier physical demands. Both roles require adherence to safety protocols, but material handlers are more exposed to fluctuating environmental factors and the operation of heavy machinery.

Career Pathways: Advancement and Training Opportunities

Packagers often start with entry-level roles focusing on assembling and packing products, with advancement opportunities leading to supervisory positions or quality control roles through on-the-job training and certification programs. Material handlers typically have broader responsibilities involving inventory management and logistics, pursuing career growth by obtaining forklift operation licenses, warehouse management certifications, and specialized training in supply chain systems. Both pathways benefit from continual skills development, but material handlers generally access a wider range of advancement options in manufacturing operations and supply chain management.

Comparing Compensation and Benefits

Packagers typically earn lower hourly wages compared to material handlers, whose responsibilities often include operating machinery and managing inventory. Material handlers frequently receive more comprehensive benefits packages, including health insurance and retirement plans, reflecting the increased skill requirements and physical demands of the role. Compensation for material handlers averages 10-15% higher than packagers, highlighting the value placed on specialized logistics and supply chain expertise in manufacturing.

Packager vs Material Handler Infographic

jobdiv.com

jobdiv.com