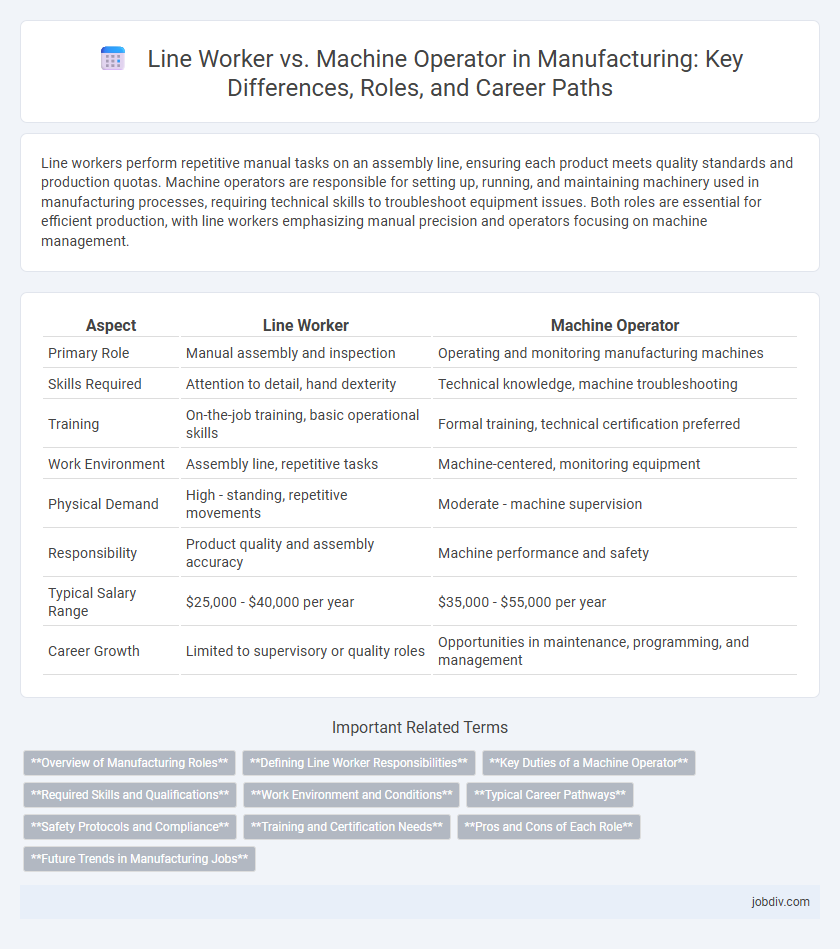

Line workers perform repetitive manual tasks on an assembly line, ensuring each product meets quality standards and production quotas. Machine operators are responsible for setting up, running, and maintaining machinery used in manufacturing processes, requiring technical skills to troubleshoot equipment issues. Both roles are essential for efficient production, with line workers emphasizing manual precision and operators focusing on machine management.

Table of Comparison

| Aspect | Line Worker | Machine Operator |

|---|---|---|

| Primary Role | Manual assembly and inspection | Operating and monitoring manufacturing machines |

| Skills Required | Attention to detail, hand dexterity | Technical knowledge, machine troubleshooting |

| Training | On-the-job training, basic operational skills | Formal training, technical certification preferred |

| Work Environment | Assembly line, repetitive tasks | Machine-centered, monitoring equipment |

| Physical Demand | High - standing, repetitive movements | Moderate - machine supervision |

| Responsibility | Product quality and assembly accuracy | Machine performance and safety |

| Typical Salary Range | $25,000 - $40,000 per year | $35,000 - $55,000 per year |

| Career Growth | Limited to supervisory or quality roles | Opportunities in maintenance, programming, and management |

Overview of Manufacturing Roles

Line workers in manufacturing perform repetitive tasks on assembly lines, focusing on manual operations such as assembling, inspecting, and packaging products. Machine operators handle and maintain complex machinery, ensuring equipment runs efficiently and troubleshooting technical issues to maintain production flow. Both roles are essential for optimizing manufacturing processes and maintaining product quality across production stages.

Defining Line Worker Responsibilities

Line workers in manufacturing are primarily responsible for assembling products, operating manual tools, and ensuring quality control at various stages of the production line. They handle tasks such as packaging, inspecting finished goods, and maintaining workstation cleanliness to optimize efficiency. Their role emphasizes hands-on involvement in the physical creation and verification of products compared to machine operators who focus more on equipment management.

Key Duties of a Machine Operator

Machine operators are responsible for setting up, controlling, and maintaining industrial machinery to ensure efficient production processes. They monitor equipment performance, perform routine inspections, and troubleshoot mechanical issues to minimize downtime. Accurate reading of blueprints and adherence to safety protocols are essential to maintain product quality and workplace safety.

Required Skills and Qualifications

Line workers require basic manual dexterity, attention to detail, and the ability to follow standardized procedures, often needing a high school diploma or equivalent. Machine operators must possess technical skills to set up, operate, and maintain complex machinery, with qualifications typically including vocational training or certifications in equipment handling. Both roles demand strong problem-solving abilities and adherence to safety protocols to ensure efficient and safe production processes.

Work Environment and Conditions

Line workers typically operate on fast-paced production floors with repetitive tasks under strict time constraints, often exposed to noise, standing for long hours, and requiring physical stamina. Machine operators work closely with equipment, focusing on machine setup, monitoring, and troubleshooting in environments that may include vibrations, heat, and safety hazards from moving parts. Both roles demand adherence to safety protocols and personal protective equipment to minimize injury risks in industrial settings.

Typical Career Pathways

Line workers typically begin their careers with entry-level roles on the production floor, gaining hands-on experience before advancing to team lead or quality control positions. Machine operators often start by mastering specific equipment and may progress to specialized technical roles, maintenance supervision, or equipment calibration experts. Both pathways offer opportunities to transition into production management or process improvement roles within manufacturing.

Safety Protocols and Compliance

Line workers and machine operators must adhere to strict safety protocols to prevent workplace accidents, including proper use of personal protective equipment (PPE) and adherence to lockout/tagout procedures. Compliance with Occupational Safety and Health Administration (OSHA) standards ensures both roles maintain safe operation of machinery and minimize exposure to hazardous materials. Regular safety training and audits reinforce awareness and help maintain regulatory compliance in manufacturing environments.

Training and Certification Needs

Line workers require comprehensive training on manual assembly techniques, safety protocols, and quality control to ensure consistent product standards. Machine operators need specialized certification in equipment handling, troubleshooting, and maintenance to operate complex machinery efficiently and safely. Both roles demand ongoing skill development to adapt to evolving manufacturing technologies and regulatory compliance.

Pros and Cons of Each Role

Line workers excel in manual dexterity and adaptability, enabling quick adjustments on assembly lines, but they often face repetitive strain and require continuous physical effort. Machine operators benefit from specialized skills in managing and maintaining complex equipment, which leads to higher efficiency and automation understanding, yet they may encounter downtime due to technical malfunctions and need ongoing technical training. Both roles are crucial in manufacturing, balancing human precision with mechanized productivity to optimize overall output.

Future Trends in Manufacturing Jobs

Line workers and machine operators face distinct shifts as Industry 4.0 integrates advanced robotics, AI, and IoT into manufacturing processes. Machine operators increasingly require skills in programming and monitoring automated systems, while line workers adapt to collaborative robots (cobots) that enhance productivity and safety on the assembly floor. Upskilling and continuous learning in digital technologies become essential for both roles to remain competitive in the evolving job market.

Line Worker vs Machine Operator Infographic

jobdiv.com

jobdiv.com