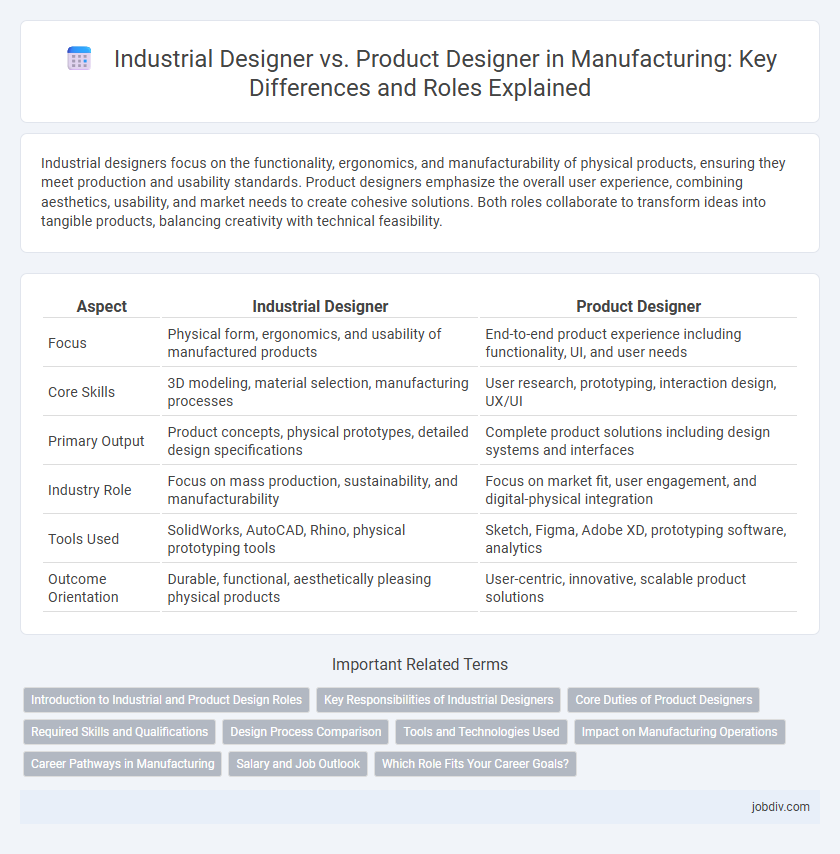

Industrial designers focus on the functionality, ergonomics, and manufacturability of physical products, ensuring they meet production and usability standards. Product designers emphasize the overall user experience, combining aesthetics, usability, and market needs to create cohesive solutions. Both roles collaborate to transform ideas into tangible products, balancing creativity with technical feasibility.

Table of Comparison

| Aspect | Industrial Designer | Product Designer |

|---|---|---|

| Focus | Physical form, ergonomics, and usability of manufactured products | End-to-end product experience including functionality, UI, and user needs |

| Core Skills | 3D modeling, material selection, manufacturing processes | User research, prototyping, interaction design, UX/UI |

| Primary Output | Product concepts, physical prototypes, detailed design specifications | Complete product solutions including design systems and interfaces |

| Industry Role | Focus on mass production, sustainability, and manufacturability | Focus on market fit, user engagement, and digital-physical integration |

| Tools Used | SolidWorks, AutoCAD, Rhino, physical prototyping tools | Sketch, Figma, Adobe XD, prototyping software, analytics |

| Outcome Orientation | Durable, functional, aesthetically pleasing physical products | User-centric, innovative, scalable product solutions |

Introduction to Industrial and Product Design Roles

Industrial designers focus on the development of mass-produced products, emphasizing ergonomics, functionality, and manufacturing processes to optimize design for efficient production. Product designers integrate user experience, aesthetics, and market research, tailoring designs to meet consumer needs and brand identity throughout the entire product lifecycle. Both roles collaborate closely with engineers and manufacturers to ensure feasibility and innovation in manufacturing industries.

Key Responsibilities of Industrial Designers

Industrial designers focus on the ergonomic, functional, and aesthetic aspects of physical products, ensuring usability, manufacturability, and consumer appeal. They develop detailed prototypes, CAD models, and specifications that guide production processes and material selection. Their key responsibilities include analyzing user needs, optimizing product performance, and collaborating with engineers to transform concepts into market-ready industrial solutions.

Core Duties of Product Designers

Product designers primarily focus on creating user-centric solutions by integrating functionality, aesthetics, and usability in manufacturing processes. They conduct extensive research, develop prototypes, and collaborate closely with engineers to refine product features and ensure manufacturability. Their core duties emphasize iterative testing and user feedback analysis to optimize product performance and market fit.

Required Skills and Qualifications

Industrial designers require strong skills in 3D modeling, materials science, and ergonomics to develop functional products suitable for mass production. Product designers emphasize user experience, proficiency in UX/UI software, and market research to create consumer-focused solutions. Both roles demand creativity, problem-solving abilities, and a background in design principles, but industrial designers often have engineering knowledge, while product designers prioritize digital interface expertise.

Design Process Comparison

Industrial designers prioritize ergonomics, materials, and manufacturing feasibility in their design process, ensuring products are practical and production-ready. Product designers focus more on user experience, interface, and aesthetic appeal, integrating market research and digital prototyping to optimize functionality and user satisfaction. Both roles require iterative testing and collaboration with engineering teams, but industrial designers emphasize physical form and production constraints, while product designers concentrate on digital interaction and user-centric solutions.

Tools and Technologies Used

Industrial designers primarily use CAD software like SolidWorks and Rhino for creating complex 3D models, along with physical prototyping tools such as 3D printers and CNC machines to test form and functionality. Product designers often utilize user experience (UX) tools like Sketch, Adobe XD, and Figma to integrate ergonomic and aesthetic factors into digital interfaces, while also employing CAD software for structural design. Both roles leverage virtual reality (VR) and augmented reality (AR) technologies to visualize designs and streamline the iteration process in manufacturing environments.

Impact on Manufacturing Operations

Industrial designers focus on the functionality, ergonomics, and manufacturability of products, directly influencing production efficiency and cost-effectiveness. Product designers integrate user requirements with technical specifications, ensuring designs align with market demand while optimizing assembly processes. Both roles collaborate to reduce material waste and streamline supply chains, enhancing overall manufacturing operations.

Career Pathways in Manufacturing

Industrial designers in manufacturing specialize in creating ergonomic, functional, and aesthetic product concepts, often collaborating closely with engineers to optimize production feasibility. Product designers focus more on refining product usability and user experience, integrating market research and consumer feedback into iterative design improvements. Career pathways for industrial designers typically lead to roles in prototyping and production engineering, while product designers may advance towards product management and user experience strategy within manufacturing firms.

Salary and Job Outlook

Industrial designers earn an average salary ranging from $60,000 to $90,000 annually, with job growth projected at 4% through 2031 according to the U.S. Bureau of Labor Statistics. Product designers typically command higher salaries, often between $70,000 and $100,000, driven by demand in technology and consumer goods sectors. The job outlook for product designers is robust, with an expected growth rate of 5% to 7%, reflecting increasing emphasis on user experience and innovation in manufacturing.

Which Role Fits Your Career Goals?

Industrial designers focus on creating and improving physical products with an emphasis on usability, functionality, and manufacturing processes, making them ideal for careers centered around engineering and production efficiency. Product designers take a broader approach by blending user experience, aesthetics, and market needs to develop both digital and physical products, suiting those aiming for roles in innovation and cross-disciplinary design. Choosing between industrial and product design depends on whether your career goals emphasize hands-on product development or integrated user-centric solutions.

Industrial Designer vs Product Designer Infographic

jobdiv.com

jobdiv.com