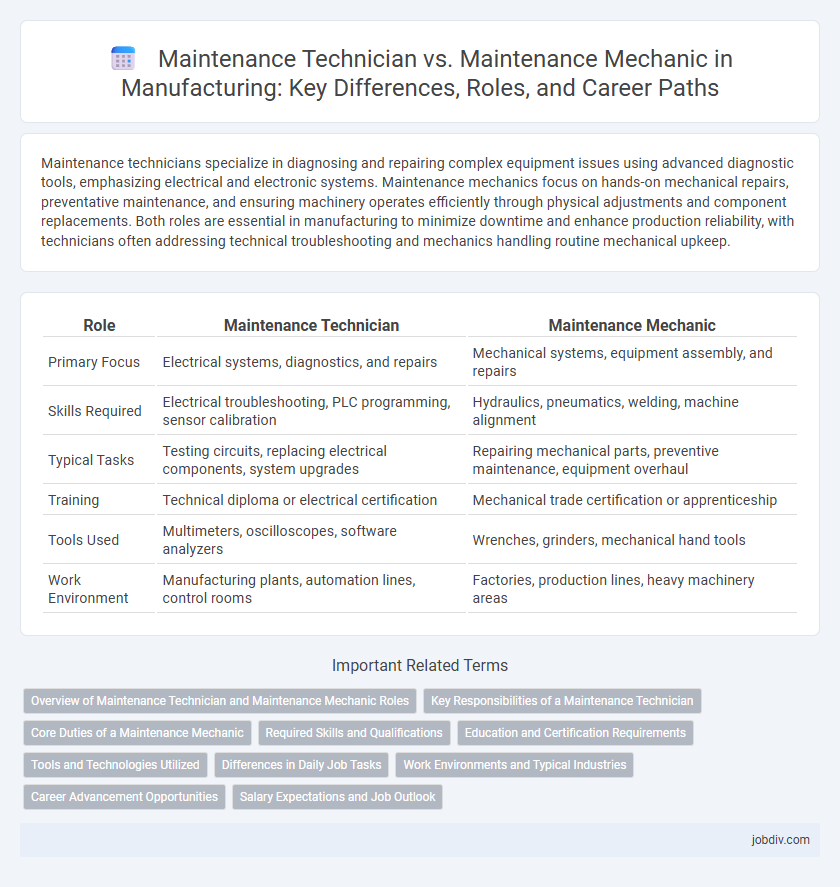

Maintenance technicians specialize in diagnosing and repairing complex equipment issues using advanced diagnostic tools, emphasizing electrical and electronic systems. Maintenance mechanics focus on hands-on mechanical repairs, preventative maintenance, and ensuring machinery operates efficiently through physical adjustments and component replacements. Both roles are essential in manufacturing to minimize downtime and enhance production reliability, with technicians often addressing technical troubleshooting and mechanics handling routine mechanical upkeep.

Table of Comparison

| Role | Maintenance Technician | Maintenance Mechanic |

|---|---|---|

| Primary Focus | Electrical systems, diagnostics, and repairs | Mechanical systems, equipment assembly, and repairs |

| Skills Required | Electrical troubleshooting, PLC programming, sensor calibration | Hydraulics, pneumatics, welding, machine alignment |

| Typical Tasks | Testing circuits, replacing electrical components, system upgrades | Repairing mechanical parts, preventive maintenance, equipment overhaul |

| Training | Technical diploma or electrical certification | Mechanical trade certification or apprenticeship |

| Tools Used | Multimeters, oscilloscopes, software analyzers | Wrenches, grinders, mechanical hand tools |

| Work Environment | Manufacturing plants, automation lines, control rooms | Factories, production lines, heavy machinery areas |

Overview of Maintenance Technician and Maintenance Mechanic Roles

Maintenance Technicians specialize in diagnosing and repairing electrical and mechanical equipment to ensure smooth manufacturing operations, focusing on preventive maintenance and system troubleshooting. Maintenance Mechanics primarily handle the installation, calibration, and mechanical upkeep of machinery, emphasizing physical repair and part replacement. Both roles are crucial for minimizing downtime and enhancing production efficiency in manufacturing environments.

Key Responsibilities of a Maintenance Technician

Maintenance Technicians primarily focus on troubleshooting, diagnosing, and repairing electrical, mechanical, and pneumatic systems to minimize equipment downtime in manufacturing environments. They perform routine inspections, calibrate instruments, and implement preventive maintenance schedules to ensure optimal machine performance and safety compliance. Their role emphasizes technical problem-solving and coordination with production teams to maintain continuous operational efficiency.

Core Duties of a Maintenance Mechanic

Maintenance Mechanics primarily focus on the hands-on repair, inspection, and preventive maintenance of machinery and equipment in manufacturing plants. Core duties include diagnosing mechanical failures, replacing worn parts, and conducting routine lubrication and adjustments to ensure optimal machine performance. Their role demands proficiency in pneumatic, hydraulic, and electrical systems to minimize downtime and maintain production efficiency.

Required Skills and Qualifications

Maintenance Technicians require a broad understanding of electrical, mechanical, and hydraulic systems, with skills in troubleshooting, preventive maintenance, and basic programming for automated equipment. Maintenance Mechanics emphasize hands-on expertise in repairing and calibrating machinery, often needing certifications in welding, pneumatic systems, and heavy equipment operation. Both roles demand strong problem-solving abilities, adherence to safety protocols, and relevant technical certifications or apprenticeships in industrial maintenance.

Education and Certification Requirements

Maintenance Technicians typically require a high school diploma or equivalent and benefit from certifications such as OSHA safety training or HVAC certification to enhance job performance. Maintenance Mechanics often need more specialized education, including vocational training or an associate degree, with certifications like NCCER (National Center for Construction Education and Research) or Journeyman Mechanical certifications to validate their advanced skills. Both roles emphasize continuous learning, but Maintenance Mechanics generally have more rigorous certification requirements reflecting their complex mechanical expertise.

Tools and Technologies Utilized

Maintenance Technicians primarily utilize diagnostic software, electrical testing equipment, and programmable logic controllers (PLCs) to troubleshoot and repair complex machinery. Maintenance Mechanics often work hands-on with hydraulic tools, hand tools, and welding equipment to perform physical repairs, alignments, and adjustments. Both roles leverage computerized maintenance management systems (CMMS) to track repairs, maintenance schedules, and parts inventories, optimizing operational efficiency.

Differences in Daily Job Tasks

Maintenance technicians primarily focus on diagnosing equipment issues using electronic diagnostic tools and performing preventive maintenance to ensure optimal operational efficiency. Maintenance mechanics concentrate on hands-on repair tasks, such as dismantling machinery, replacing worn parts, and adjusting mechanical components to restore functionality. While technicians emphasize troubleshooting and system analysis, mechanics specialize in manual repairs and mechanical assembly within manufacturing environments.

Work Environments and Typical Industries

Maintenance Technicians typically work in diverse manufacturing settings including food processing, pharmaceuticals, and electronics assembly, often focusing on electrical systems and control panels. Maintenance Mechanics are commonly found in heavy industries such as automotive manufacturing, steel production, and chemical plants, where they handle mechanical repairs and equipment overhauls. Both roles require adapting to industrial environments but vary in specialization based on the machinery and technological complexity present in their respective sectors.

Career Advancement Opportunities

Maintenance technicians often advance by developing specialized skills in electrical or mechanical systems, leading to supervisory roles or technical specialist positions. Maintenance mechanics typically progress through hands-on experience and certifications, enabling them to manage complex machinery or transition into maintenance management. Both career paths offer opportunities in preventive maintenance, reliability engineering, and operational leadership within manufacturing environments.

Salary Expectations and Job Outlook

Maintenance Technicians typically earn between $40,000 and $60,000 annually, reflecting their role in routine equipment inspections and minor repairs, while Maintenance Mechanics often command salaries from $50,000 to $70,000 due to their specialized skills in complex machinery troubleshooting and overhauls. The job outlook for Maintenance Mechanics is expected to grow by 8% over the next decade, driven by advanced manufacturing demands and automation, whereas Maintenance Technicians face a steadier growth rate of around 5%. Both roles are critical in manufacturing environments, but Mechanics generally enjoy higher wage potential and stronger demand due to their technical expertise.

Maintenance Technician vs Maintenance Mechanic Infographic

jobdiv.com

jobdiv.com