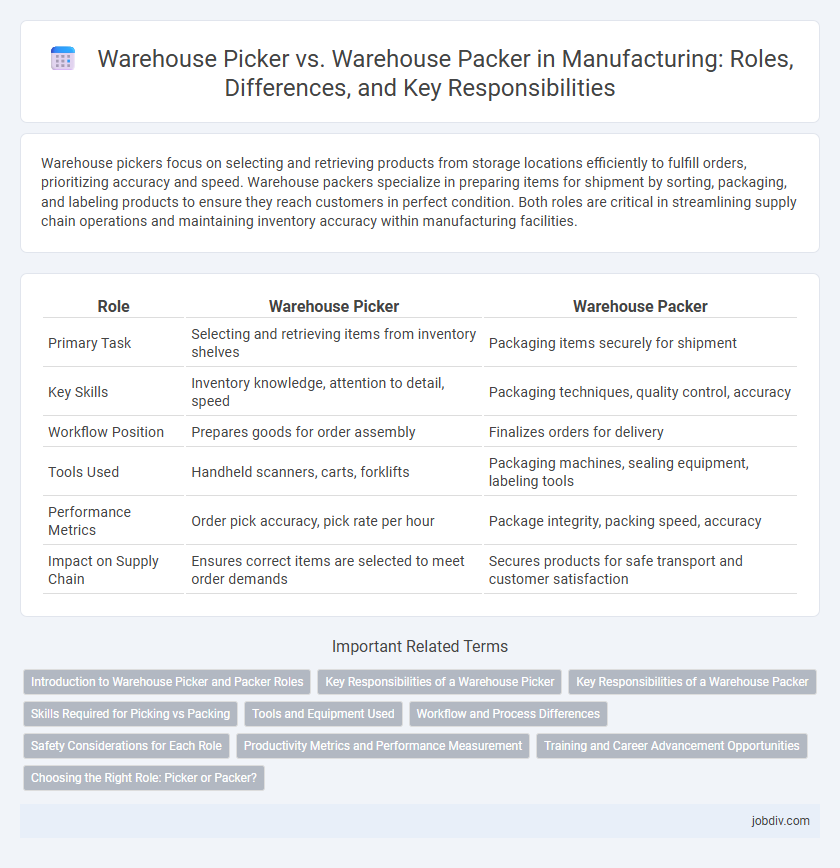

Warehouse pickers focus on selecting and retrieving products from storage locations efficiently to fulfill orders, prioritizing accuracy and speed. Warehouse packers specialize in preparing items for shipment by sorting, packaging, and labeling products to ensure they reach customers in perfect condition. Both roles are critical in streamlining supply chain operations and maintaining inventory accuracy within manufacturing facilities.

Table of Comparison

| Role | Warehouse Picker | Warehouse Packer |

|---|---|---|

| Primary Task | Selecting and retrieving items from inventory shelves | Packaging items securely for shipment |

| Key Skills | Inventory knowledge, attention to detail, speed | Packaging techniques, quality control, accuracy |

| Workflow Position | Prepares goods for order assembly | Finalizes orders for delivery |

| Tools Used | Handheld scanners, carts, forklifts | Packaging machines, sealing equipment, labeling tools |

| Performance Metrics | Order pick accuracy, pick rate per hour | Package integrity, packing speed, accuracy |

| Impact on Supply Chain | Ensures correct items are selected to meet order demands | Secures products for safe transport and customer satisfaction |

Introduction to Warehouse Picker and Packer Roles

Warehouse pickers are responsible for accurately selecting and retrieving products from storage locations based on customer orders, ensuring inventory accuracy and timely fulfillment. Warehouse packers specialize in securely packaging items, labeling shipments, and preparing orders for dispatch to prevent damage and maintain product quality. Both roles are critical components of efficient warehouse operations, contributing to streamlined supply chain processes and customer satisfaction.

Key Responsibilities of a Warehouse Picker

A Warehouse Picker is responsible for accurately selecting and retrieving items from inventory based on order specifications, ensuring the correct quantity and quality of products are gathered. They operate barcode scanners, maintain organized picking lists, and report discrepancies to inventory control to optimize order fulfillment processes. Effective coordination with packers and adherence to safety protocols are essential to maintain workflow efficiency and reduce errors.

Key Responsibilities of a Warehouse Packer

Warehouse packers are responsible for accurately assembling products and preparing them for shipment by securely packing items according to company standards. They must ensure that all packages are labeled correctly, complete with shipping documentation and compliance with safety regulations. Efficient packing minimizes product damage during transit and supports timely delivery in the manufacturing supply chain.

Skills Required for Picking vs Packing

Warehouse pickers require strong attention to detail and proficiency in navigating inventory systems to efficiently locate items, prioritize order accuracy, and maintain speed during high-volume retrievals. Warehouse packers need expertise in packaging techniques, quality control, and safe material handling to ensure items are securely packed, damage-free, and meet shipping standards. Both roles demand physical stamina and teamwork, but pickers emphasize item identification skills while packers focus on protective packaging and labeling precision.

Tools and Equipment Used

Warehouse pickers predominantly use handheld barcode scanners, picking carts, and RF (radio frequency) devices for efficient item identification and retrieval. Warehouse packers rely mainly on packing tables, tape dispensers, box cutters, and label printers to ensure accurate and secure packaging. Both roles often utilize forklifts and pallet jacks for moving goods, but their toolsets are specialized to optimize either picking accuracy or packing speed.

Workflow and Process Differences

Warehouse pickers focus on locating and selecting specific items from inventory based on order lists, optimizing accuracy and speed in the retrieval process. Warehouse packers prioritize assembling, packaging, and labeling the picked items to ensure safe shipment and compliance with shipping requirements. The workflow differentiation lies in pickers handling item selection upstream, while packers manage the final preparation stage before distribution, requiring distinct operational skills and process controls.

Safety Considerations for Each Role

Warehouse pickers prioritize safety by using ergonomic tools and proper lifting techniques to reduce strain and prevent musculoskeletal injuries during item retrieval. Warehouse packers focus on minimizing repetitive motion injuries by organizing workstations for efficient packing and employing protective gear to avoid cuts, punctures, and contact with hazardous materials. Both roles implement strict adherence to safety protocols, including the use of personal protective equipment (PPE) and regular training on emergency procedures to ensure a secure working environment.

Productivity Metrics and Performance Measurement

Warehouse pickers and packers play distinct roles in manufacturing logistics, where productivity metrics such as orders picked per hour and accuracy rate are crucial for pickers. Packers are often evaluated based on packing speed, package integrity, and error rates, which directly impact shipment quality and customer satisfaction. Performance measurement systems utilizing barcode scanning and real-time data analytics help optimize workflows by identifying bottlenecks and ensuring both picking and packing processes meet efficiency targets.

Training and Career Advancement Opportunities

Warehouse pickers receive specialized training in inventory management, order accuracy, and efficient route planning, laying the foundation for advancement into supervisory roles or inventory control positions. Packers develop expertise in packaging standards, quality assurance, and equipment handling, enabling career growth toward quality control inspector or logistics coordinator roles. Cross-training in both picking and packing enhances skill versatility, increasing promotion prospects within manufacturing warehouse operations.

Choosing the Right Role: Picker or Packer?

Choosing between a warehouse picker and a warehouse packer depends on the specific operational needs of the manufacturing supply chain. Warehouse pickers excel in accurately retrieving items from inventory, ensuring efficient order fulfillment, while warehouse packers specialize in securely packaging products to minimize damage during shipping. Optimizing labor allocation by matching skills to tasks enhances productivity and reduces errors in inventory management.

Warehouse Picker vs Warehouse Packer Infographic

jobdiv.com

jobdiv.com