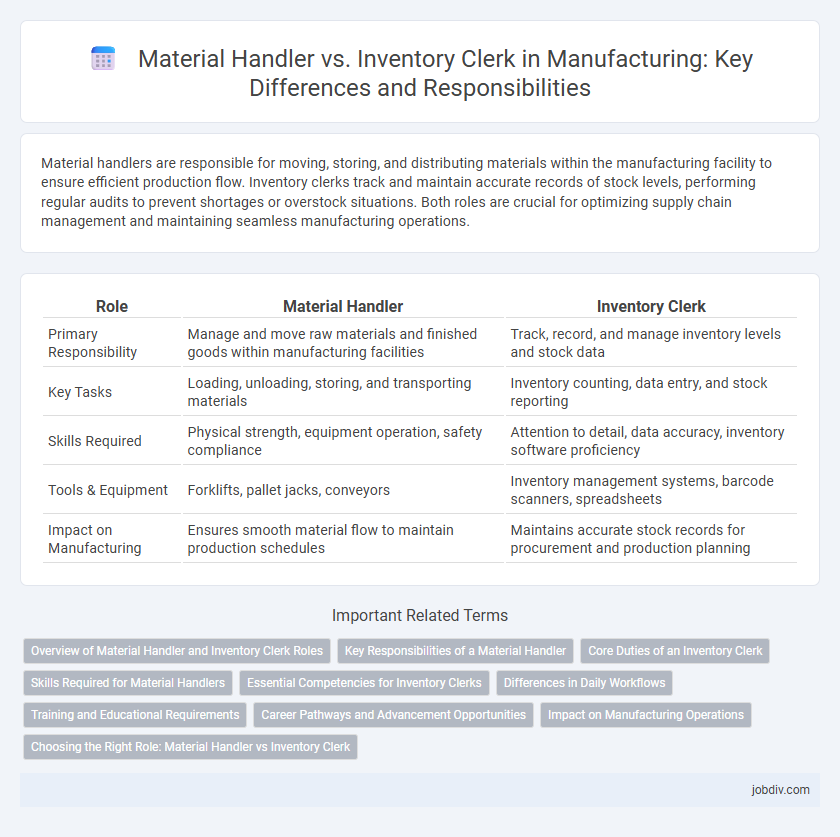

Material handlers are responsible for moving, storing, and distributing materials within the manufacturing facility to ensure efficient production flow. Inventory clerks track and maintain accurate records of stock levels, performing regular audits to prevent shortages or overstock situations. Both roles are crucial for optimizing supply chain management and maintaining seamless manufacturing operations.

Table of Comparison

| Role | Material Handler | Inventory Clerk |

|---|---|---|

| Primary Responsibility | Manage and move raw materials and finished goods within manufacturing facilities | Track, record, and manage inventory levels and stock data |

| Key Tasks | Loading, unloading, storing, and transporting materials | Inventory counting, data entry, and stock reporting |

| Skills Required | Physical strength, equipment operation, safety compliance | Attention to detail, data accuracy, inventory software proficiency |

| Tools & Equipment | Forklifts, pallet jacks, conveyors | Inventory management systems, barcode scanners, spreadsheets |

| Impact on Manufacturing | Ensures smooth material flow to maintain production schedules | Maintains accurate stock records for procurement and production planning |

Overview of Material Handler and Inventory Clerk Roles

Material Handlers are responsible for moving, storing, and distributing materials within manufacturing facilities, ensuring the timely availability of components for production lines. Inventory Clerks monitor stock levels, record inventory data, and maintain accurate inventory documentation using software systems to prevent shortages and overstock situations. Both roles are critical for optimizing supply chain efficiency and supporting seamless manufacturing operations.

Key Responsibilities of a Material Handler

Material Handlers are responsible for efficiently moving raw materials, components, and finished products within manufacturing facilities, ensuring timely supply to production lines. They operate forklifts and other material handling equipment, maintain accurate inventory records, and perform quality checks to prevent damage or loss. Their role is critical in optimizing workflow, minimizing production downtime, and supporting just-in-time manufacturing processes.

Core Duties of an Inventory Clerk

Inventory Clerks in manufacturing oversee accurate record-keeping of stock levels, ensuring timely replenishment and reduction of material shortages. They conduct regular audits and reconcile physical inventory with system data to maintain data integrity. These core duties optimize inventory management, directly supporting production efficiency and minimizing operational downtime.

Skills Required for Material Handlers

Material Handlers in manufacturing require strong physical stamina, proficiency in operating forklifts and pallet jacks, and expertise in reading inventory software to track materials accurately. They must possess effective communication skills to coordinate with production teams and quality control, ensuring timely delivery of raw materials. Knowledge of safety regulations and warehouse management systems is essential for maintaining an organized and hazard-free work environment.

Essential Competencies for Inventory Clerks

Inventory Clerks require strong organizational skills, attention to detail, and proficiency in inventory management software to accurately track stock levels and process orders. Mastery of data entry, barcode scanning, and understanding of supply chain processes ensures efficient inventory control and reporting. Effective communication and problem-solving abilities aid in coordinating with vendors and resolving discrepancies.

Differences in Daily Workflows

Material Handlers in manufacturing primarily focus on physically moving, storing, and organizing raw materials and finished goods within the facility, ensuring timely delivery to production lines. Inventory Clerks concentrate on tracking stock levels, maintaining accurate records in inventory management systems, and conducting regular audits to prevent discrepancies. The key difference in daily workflows lies in the Material Handler's operational tasks versus the Inventory Clerk's administrative and data management responsibilities.

Training and Educational Requirements

Material Handler roles typically require a high school diploma or equivalent, emphasizing practical training in equipment operation, safety protocols, and inventory management systems. Inventory Clerks generally need more advanced education, often including specialized courses in logistics, supply chain management, or computer software related to inventory tracking. Both positions benefit from on-the-job training, but Inventory Clerks usually undergo additional instruction in data analysis and organizational skills to accurately manage and report stock levels.

Career Pathways and Advancement Opportunities

Material Handlers in manufacturing often advance by gaining certifications in forklift operation and logistics, leading to roles in warehouse supervision or supply chain management. Inventory Clerks typically progress by developing expertise in inventory control software and data analysis, opening pathways to inventory management or procurement specialist positions. Both roles offer foundational experience with distinct career trajectories emphasizing operational efficiency and resource management.

Impact on Manufacturing Operations

Material Handlers directly influence manufacturing operations by efficiently moving raw materials and finished goods, ensuring seamless production flow and minimizing downtime. Inventory Clerks maintain accurate records of inventory levels, preventing stockouts and overstock situations that can disrupt manufacturing schedules. Both roles are critical for optimizing supply chain efficiency and supporting on-time product delivery.

Choosing the Right Role: Material Handler vs Inventory Clerk

Selecting between a Material Handler and an Inventory Clerk depends on operational needs, as Material Handlers focus on physically moving, organizing, and maintaining raw materials and products within the manufacturing environment. Inventory Clerks specialize in tracking stock levels, updating inventory records, and conducting audits to ensure accuracy and prevent discrepancies. Understanding the distinction in responsibilities ensures manufacturers optimize workflow efficiency and maintain precise inventory control.

Material Handler vs Inventory Clerk Infographic

jobdiv.com

jobdiv.com