Assemblers focus on putting together components and parts to create finished products, using manual tools or automated machinery to ensure precision and efficiency. Fabricators are responsible for cutting, shaping, and welding raw materials, often metal, to produce structural parts or assemblies. Understanding the distinct roles of assemblers and fabricators enhances workforce allocation and improves production workflow in manufacturing operations.

Table of Comparison

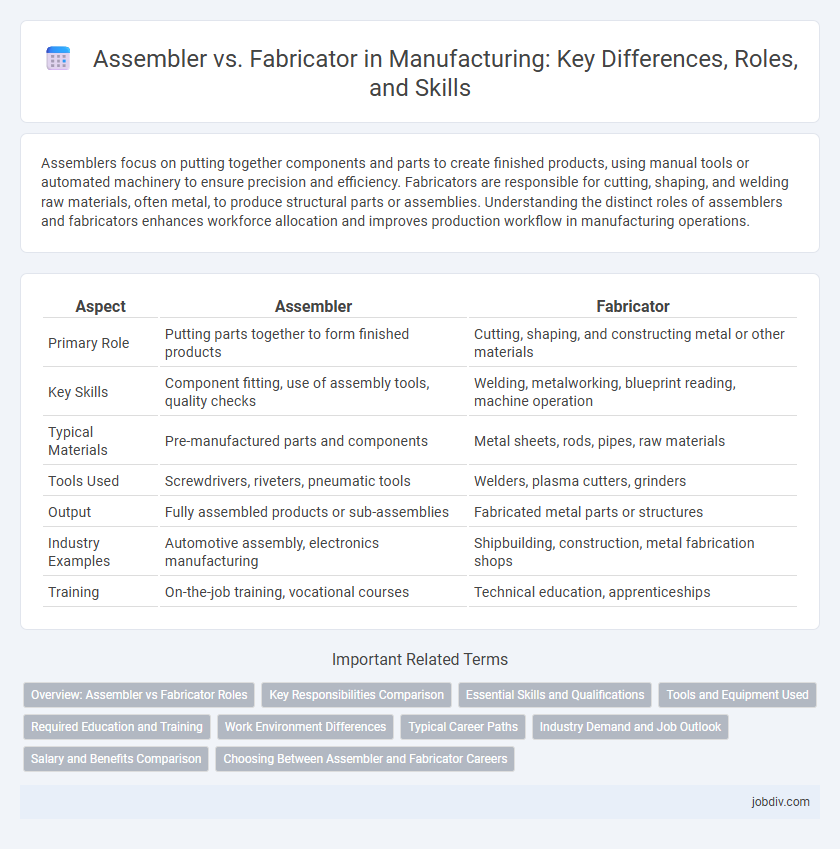

| Aspect | Assembler | Fabricator |

|---|---|---|

| Primary Role | Putting parts together to form finished products | Cutting, shaping, and constructing metal or other materials |

| Key Skills | Component fitting, use of assembly tools, quality checks | Welding, metalworking, blueprint reading, machine operation |

| Typical Materials | Pre-manufactured parts and components | Metal sheets, rods, pipes, raw materials |

| Tools Used | Screwdrivers, riveters, pneumatic tools | Welders, plasma cutters, grinders |

| Output | Fully assembled products or sub-assemblies | Fabricated metal parts or structures |

| Industry Examples | Automotive assembly, electronics manufacturing | Shipbuilding, construction, metal fabrication shops |

| Training | On-the-job training, vocational courses | Technical education, apprenticeships |

Overview: Assembler vs Fabricator Roles

Assemblers primarily focus on putting together parts and components according to specific instructions or blueprints, ensuring precise alignment and functionality in manufacturing processes. Fabricators work with raw materials, using cutting, shaping, and welding techniques to create parts or structures that meet detailed specifications. Both roles are essential in production lines but differ in skillsets and stages of product development, with assemblers emphasizing assembly precision and fabricators requiring material manipulation expertise.

Key Responsibilities Comparison

Assemblers primarily focus on putting together components according to detailed blueprints or specifications, ensuring precise alignment and secure fastening during the manufacturing process. Fabricators specialize in shaping, cutting, and welding raw materials such as metal sheets or pipes to create custom parts or structures that meet exact design requirements. Both roles demand strong technical skills and adherence to safety standards, but fabricators often require expertise in operating heavy machinery and interpreting complex material properties.

Essential Skills and Qualifications

Assemblers require proficiency in reading blueprints, basic hand tools operation, and component alignment to ensure precise assembly of parts. Fabricators demand advanced skills in welding, metalworking, and interpreting technical drawings to construct and modify metal structures. Both roles benefit from strong attention to detail, manual dexterity, and familiarity with safety protocols in manufacturing environments.

Tools and Equipment Used

Assemblers primarily use hand tools such as screwdrivers, pliers, and torque wrenches to piece together components based on detailed specifications, often relying on jigs and fixtures for precision. Fabricators operate heavy machinery including welding machines, cutting torches, and CNC equipment to shape, cut, and join raw materials into finished parts or structures. The key distinction lies in assemblers focusing on assembly with fastening and fitting tools, while fabricators work extensively with metalworking and fabrication tools for material manipulation.

Required Education and Training

Assemblers typically require a high school diploma or equivalent, with training often provided on the job to develop skills in reading blueprints and operating machinery. Fabricators usually need more advanced technical training, such as vocational schooling or an associate degree in welding, machining, or metalworking, to handle complex fabrication processes. Both roles demand hands-on experience, but fabricators generally engage in more specialized training for precision and custom part creation.

Work Environment Differences

Assemblers typically work in controlled factory settings with assembly lines that emphasize repetitive, precise tasks using small parts, often in clean and well-lit environments. Fabricators operate in more varied industrial or workshop environments involving heavy machinery, metal cutting, welding, and material shaping, which may expose them to louder noise levels and higher physical demands. The difference in work environments highlights the distinction between fine assembly work versus heavy material processing and structural creation.

Typical Career Paths

Assemblers often begin their careers in entry-level assembly positions, advancing through roles such as lead assembler or quality control inspector before transitioning into supervisory or production management roles. Fabricators typically progress from apprenticeships or trade school backgrounds to skilled fabricator roles, with potential growth into specialized welding, machining, or fabrication technician positions. Both career paths offer opportunities for advancement into engineering, project management, or operations management within manufacturing industries.

Industry Demand and Job Outlook

Industry demand for assemblers remains strong in sectors like automotive and electronics, driven by mass production and automation trends. Fabricators face steady job outlooks in metalworking and construction, with increasing need for skilled workers in customized manufacturing processes. Both roles require adaptability to technological advancements, but fabricators often command higher wages due to specialized skill requirements.

Salary and Benefits Comparison

Assemblers typically earn an average hourly wage of $15 to $20, while fabricators can command higher pay, ranging from $18 to $25 per hour, reflecting their specialized skills in shaping and welding metal components. Benefits for both roles often include health insurance, retirement plans, and paid time off, but fabricators frequently receive enhanced benefits packages due to the higher-risk nature of their work. Overtime opportunities and skill-based bonuses are more common among fabricators, contributing to a greater overall compensation package in manufacturing settings.

Choosing Between Assembler and Fabricator Careers

Choosing between assembler and fabricator careers depends on skill set and career goals within manufacturing. Assemblers typically focus on putting together components following detailed instructions, requiring strong attention to precision and consistency. Fabricators often work with raw materials to create parts using welding, cutting, and shaping techniques, demanding technical expertise in metalworking and machinery operation.

Assembler vs Fabricator Infographic

jobdiv.com

jobdiv.com