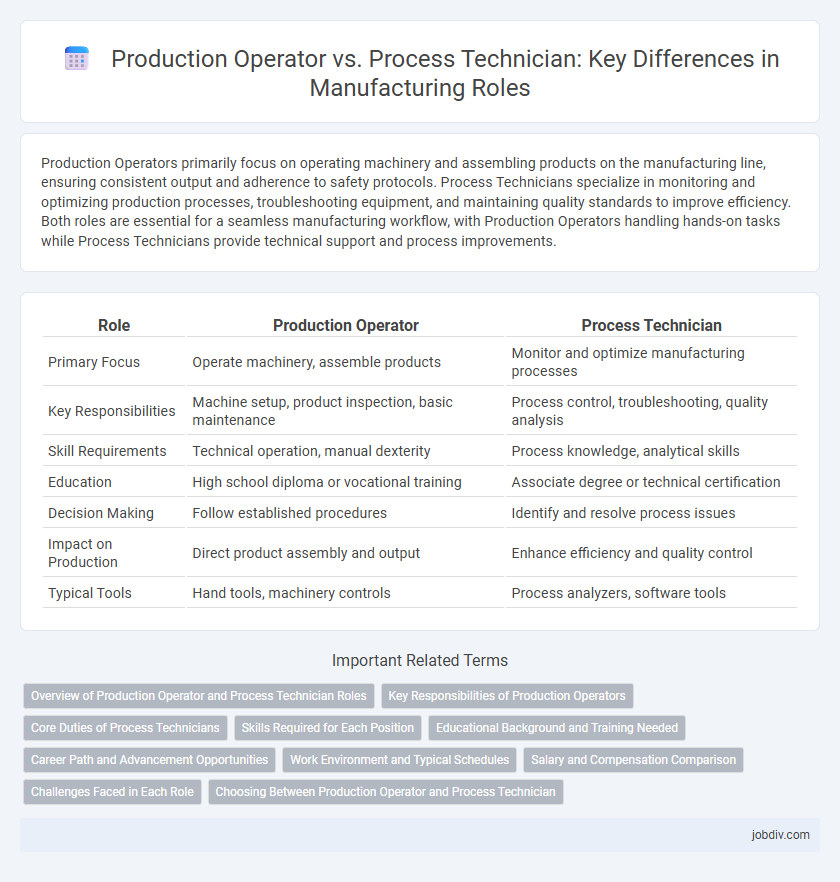

Production Operators primarily focus on operating machinery and assembling products on the manufacturing line, ensuring consistent output and adherence to safety protocols. Process Technicians specialize in monitoring and optimizing production processes, troubleshooting equipment, and maintaining quality standards to improve efficiency. Both roles are essential for a seamless manufacturing workflow, with Production Operators handling hands-on tasks while Process Technicians provide technical support and process improvements.

Table of Comparison

| Role | Production Operator | Process Technician |

|---|---|---|

| Primary Focus | Operate machinery, assemble products | Monitor and optimize manufacturing processes |

| Key Responsibilities | Machine setup, product inspection, basic maintenance | Process control, troubleshooting, quality analysis |

| Skill Requirements | Technical operation, manual dexterity | Process knowledge, analytical skills |

| Education | High school diploma or vocational training | Associate degree or technical certification |

| Decision Making | Follow established procedures | Identify and resolve process issues |

| Impact on Production | Direct product assembly and output | Enhance efficiency and quality control |

| Typical Tools | Hand tools, machinery controls | Process analyzers, software tools |

Overview of Production Operator and Process Technician Roles

Production Operators oversee day-to-day manufacturing activities, ensuring machinery runs efficiently and products meet quality standards. Process Technicians specialize in optimizing production processes by troubleshooting equipment, conducting tests, and implementing improvements to enhance operational efficiency. Both roles are critical in maintaining seamless manufacturing workflows and product consistency.

Key Responsibilities of Production Operators

Production Operators are primarily responsible for operating machinery, monitoring equipment performance, and ensuring production line efficiency within manufacturing plants. They conduct routine inspections, troubleshoot minor mechanical issues, and maintain production schedules to meet output targets. Their role emphasizes maintaining safety standards, adhering to quality control protocols, and performing basic maintenance to support continuous manufacturing processes.

Core Duties of Process Technicians

Process Technicians in manufacturing oversee the monitoring and optimization of production processes, ensuring equipment operates efficiently and within quality standards. They troubleshoot technical issues, perform routine maintenance, and adjust process parameters to maintain product consistency and safety. Unlike Production Operators, Process Technicians focus on controlling process variables and implementing process improvements to enhance manufacturing output.

Skills Required for Each Position

Production Operators require skills in machine operation, quality control, and basic troubleshooting to ensure efficient assembly line performance. Process Technicians need advanced expertise in process optimization, data analysis, and equipment calibration to maintain consistent production standards. Both roles demand strong attention to detail, safety compliance, and the ability to read technical documents and schematics.

Educational Background and Training Needed

Production Operators typically require a high school diploma or equivalent, with on-the-job training emphasizing equipment operation and safety protocols. Process Technicians often hold an associate degree or technical certification in fields like manufacturing technology or process control, with specialized training in system monitoring and quality assurance. Both roles demand hands-on experience, but Process Technicians usually undergo more advanced training to handle complex process adjustments and troubleshooting.

Career Path and Advancement Opportunities

Production Operators typically start in entry-level roles focused on machine operation and assembly line tasks, offering foundational skills in manufacturing processes. Process Technicians often require specialized technical knowledge and tend to advance into roles involving quality control, process optimization, and equipment maintenance. Career advancement for Process Technicians generally leads to supervisory or engineering positions, while Production Operators may progress through skill development and cross-training to higher operational roles.

Work Environment and Typical Schedules

Production Operators typically work on fast-paced manufacturing floors, operating machinery and monitoring assembly lines in environments that may involve noise, heat, and repetitive tasks. Their schedules often include rotating shifts, nights, weekends, and overtime to maintain continuous production. Process Technicians usually work in more controlled settings such as laboratories or clean rooms, focusing on monitoring and optimizing industrial processes, with standard daytime hours and occasional extended shifts for troubleshooting or process adjustments.

Salary and Compensation Comparison

Production Operators typically earn a median salary ranging from $35,000 to $45,000 annually, while Process Technicians often have higher earning potential with salaries between $45,000 and $60,000 per year. Compensation for Process Technicians frequently includes performance bonuses and shift differentials due to their specialized skills in monitoring and optimizing manufacturing processes. Salary variations reflect experience levels, certifications, and geographic location within the manufacturing industry.

Challenges Faced in Each Role

Production Operators frequently confront challenges such as maintaining consistent output quality while managing machine downtime and adhering to strict production schedules. Process Technicians face complex troubleshooting of equipment malfunctions and must optimize process variables to improve efficiency and product quality under high-pressure environments. Both roles require strong attention to detail, but Process Technicians often deal with more technical diagnostics and process improvements compared to the more execution-focused tasks of Production Operators.

Choosing Between Production Operator and Process Technician

Choosing between a Production Operator and a Process Technician depends on skill complexity and responsibility level within manufacturing workflows. Production Operators focus on operating machinery and assembling products following standard procedures, while Process Technicians handle equipment calibration, process monitoring, and troubleshooting to maintain product quality. Companies seeking efficient production line performance prioritize hiring Production Operators, whereas those aiming for process optimization and technical expertise prefer Process Technicians.

Production Operator vs Process Technician Infographic

jobdiv.com

jobdiv.com