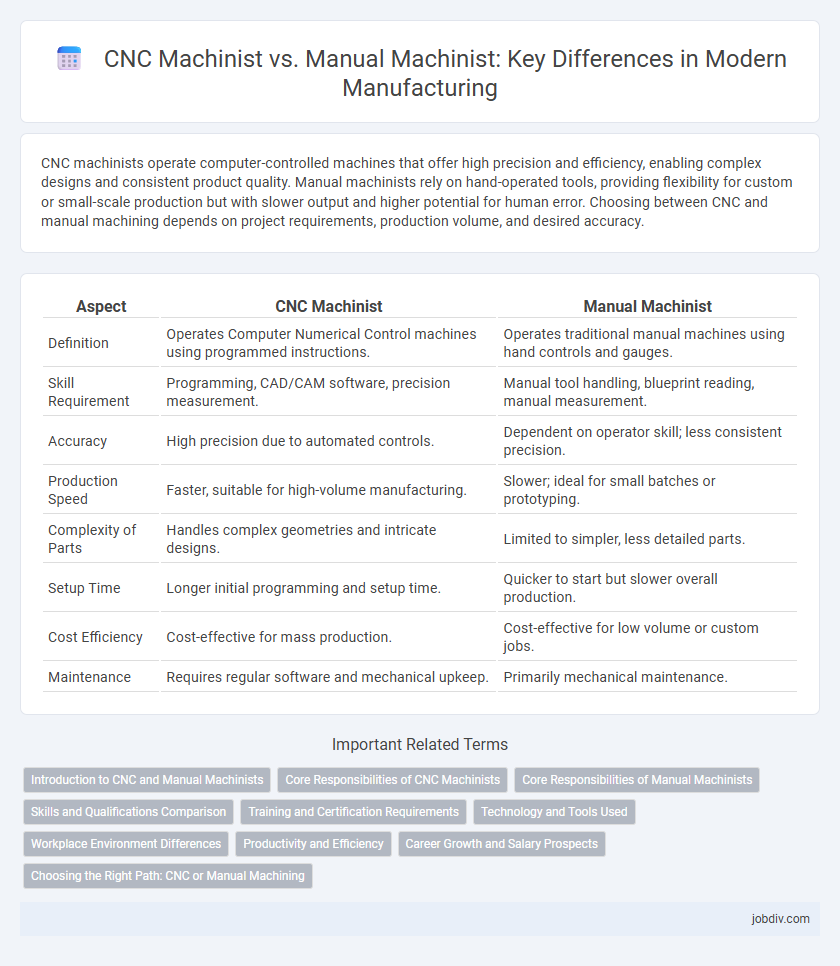

CNC machinists operate computer-controlled machines that offer high precision and efficiency, enabling complex designs and consistent product quality. Manual machinists rely on hand-operated tools, providing flexibility for custom or small-scale production but with slower output and higher potential for human error. Choosing between CNC and manual machining depends on project requirements, production volume, and desired accuracy.

Table of Comparison

| Aspect | CNC Machinist | Manual Machinist |

|---|---|---|

| Definition | Operates Computer Numerical Control machines using programmed instructions. | Operates traditional manual machines using hand controls and gauges. |

| Skill Requirement | Programming, CAD/CAM software, precision measurement. | Manual tool handling, blueprint reading, manual measurement. |

| Accuracy | High precision due to automated controls. | Dependent on operator skill; less consistent precision. |

| Production Speed | Faster, suitable for high-volume manufacturing. | Slower; ideal for small batches or prototyping. |

| Complexity of Parts | Handles complex geometries and intricate designs. | Limited to simpler, less detailed parts. |

| Setup Time | Longer initial programming and setup time. | Quicker to start but slower overall production. |

| Cost Efficiency | Cost-effective for mass production. | Cost-effective for low volume or custom jobs. |

| Maintenance | Requires regular software and mechanical upkeep. | Primarily mechanical maintenance. |

Introduction to CNC and Manual Machinists

CNC machinists operate computer numerical control machines that execute precise, programmed movements to shape metal and other materials, enhancing consistency and efficiency in manufacturing. Manual machinists rely on hand-operated tools and manual controls to shape and finish parts, requiring extensive skill and experience to maintain accuracy. The choice between CNC and manual machining impacts production speed, precision, and labor costs, with CNC technology favored for complex, high-volume tasks.

Core Responsibilities of CNC Machinists

CNC machinists operate computer-controlled machines to produce precision metal parts by interpreting blueprints and programming CNC equipment for automated manufacturing processes. They perform routine maintenance on machines, ensure high accuracy through measurement tools, and adjust machine settings to meet strict tolerances. Unlike manual machinists who rely on hand tools and manual control, CNC machinists focus on software programming, automation optimization, and production efficiency in manufacturing environments.

Core Responsibilities of Manual Machinists

Manual machinists focus on operating traditional hand-operated machines such as lathes, mills, and grinders to shape metal parts with precision, relying heavily on their skill and experience. They interpret blueprints and technical drawings to measure and cut materials manually, ensuring dimensional accuracy through direct adjustments and hands-on tooling. Unlike CNC machinists who program and oversee automated machines, manual machinists perform routine maintenance and troubleshoot mechanical issues through manual intervention to maintain production quality.

Skills and Qualifications Comparison

CNC machinists require proficiency in computer-aided design (CAD) software, G-code programming, and machine operation to produce precision parts efficiently, whereas manual machinists depend heavily on hands-on skills such as manual tool control, blueprint reading, and mechanical judgment. Certifications like NIMS for CNC machinists underscore technical expertise in automated machinery, while manual machinists often gain qualifications through apprenticeships emphasizing traditional machining techniques. Both roles demand strong attention to detail and understanding of metallurgy, but CNC machinists must integrate digital technology skills with mechanical knowledge to meet modern manufacturing standards.

Training and Certification Requirements

CNC machinists require specialized training in computer programming, CAD/CAM software, and machine operation, often obtaining certifications such as those from the National Institute for Metalworking Skills (NIMS). Manual machinists typically acquire skills through apprenticeships and hands-on experience, with certification focusing on precision measurement and manual tooling techniques. Both roles value certifications that validate machining proficiency, but CNC machinists emphasize digital and software expertise while manual machinists prioritize mechanical skill mastery.

Technology and Tools Used

CNC machinists utilize computer numerical control technology to operate precision machines, enabling automated and highly accurate production of complex parts through software-driven commands. Manual machinists rely on traditional hand-operated tools and machines like lathes, mills, and grinders, requiring extensive skill to manually adjust settings and achieve precision. Advanced CNC equipment incorporates CAD/CAM software integration, real-time monitoring, and multi-axis capabilities, vastly increasing efficiency and repeatability compared to conventional manual machining techniques.

Workplace Environment Differences

CNC machinists operate in highly automated, computer-controlled environments that demand precision programming and consistent monitoring of machines, often resulting in cleaner, quieter workspaces with enhanced safety measures. Manual machinists work directly with hand-operated or power tools, requiring physical dexterity and adaptability in more variable conditions, typically facing higher noise levels and exposure to manual handling hazards. The shift from manual to CNC machining significantly changes workplace ergonomics, skill requirements, and the pace of production.

Productivity and Efficiency

CNC machinists significantly enhance productivity by utilizing computer-controlled machines that execute precise, repeatable cuts at high speeds, reducing human error and downtime. Manual machinists rely on hand-operated tools and traditional techniques, which often result in slower production rates and greater variability in part quality. The integration of CNC technology streamlines manufacturing processes, boosts efficiency, and enables complex designs that are challenging to achieve manually.

Career Growth and Salary Prospects

CNC machinists typically enjoy faster career growth and higher salary prospects due to the increasing demand for advanced automated manufacturing skills. Manual machinists often face slower advancement opportunities as manual machining becomes less prevalent in modern production environments. Proficiency in CNC technology significantly enhances earning potential and opens doors to specialized roles in precision manufacturing.

Choosing the Right Path: CNC or Manual Machining

CNC machinists operate computer-controlled machines that offer precision, repeatability, and efficiency in manufacturing complex parts, making them ideal for high-volume production and intricate designs. Manual machinists rely on hand-operated tools and machines, providing flexibility and hands-on expertise suited for custom, low-volume, or prototype work where adaptability and craftsmanship are critical. Choosing between CNC and manual machining depends on factors such as production volume, design complexity, budget constraints, and the required skill set for quality and operational efficiency.

CNC Machinist vs Manual Machinist Infographic

jobdiv.com

jobdiv.com