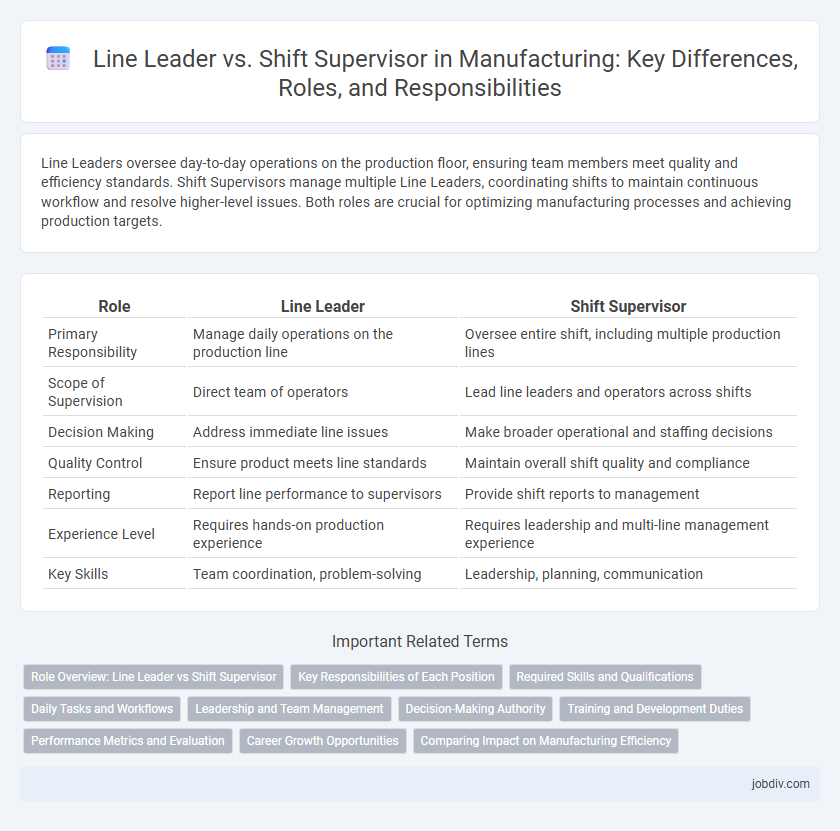

Line Leaders oversee day-to-day operations on the production floor, ensuring team members meet quality and efficiency standards. Shift Supervisors manage multiple Line Leaders, coordinating shifts to maintain continuous workflow and resolve higher-level issues. Both roles are crucial for optimizing manufacturing processes and achieving production targets.

Table of Comparison

| Role | Line Leader | Shift Supervisor |

|---|---|---|

| Primary Responsibility | Manage daily operations on the production line | Oversee entire shift, including multiple production lines |

| Scope of Supervision | Direct team of operators | Lead line leaders and operators across shifts |

| Decision Making | Address immediate line issues | Make broader operational and staffing decisions |

| Quality Control | Ensure product meets line standards | Maintain overall shift quality and compliance |

| Reporting | Report line performance to supervisors | Provide shift reports to management |

| Experience Level | Requires hands-on production experience | Requires leadership and multi-line management experience |

| Key Skills | Team coordination, problem-solving | Leadership, planning, communication |

Role Overview: Line Leader vs Shift Supervisor

Line Leaders in manufacturing oversee specific production lines, ensuring workflow efficiency and quality control while coordinating with machine operators and assemblers. Shift Supervisors manage the entire shift, handling workforce allocation, production targets, and operational issues across multiple lines to maintain overall plant performance. The Line Leader focuses on direct process supervision, whereas the Shift Supervisor takes a broader managerial role over the full shift operations.

Key Responsibilities of Each Position

Line Leaders manage day-to-day operations on the production floor, ensuring workers adhere to safety protocols and maintain quality standards. Shift Supervisors oversee entire shifts, coordinating multiple line leaders, managing workflow efficiency, and addressing production issues in real time. Both roles require strong leadership skills, but shift supervisors carry broader responsibilities including staffing, scheduling, and reporting production metrics.

Required Skills and Qualifications

Line Leaders require strong technical knowledge of production processes, proficiency in quality control, and effective team coordination skills to maintain workflow efficiency. Shift Supervisors demand advanced leadership abilities, expertise in safety regulations, and experience in handling shift-level problem-solving and decision-making under pressure. Both roles prioritize communication skills, but Shift Supervisors typically need higher qualifications, such as certifications in management or industrial engineering.

Daily Tasks and Workflows

Line Leaders oversee daily production activities, ensuring machine operators meet output targets and maintain quality standards. Shift Supervisors manage multiple lines during their shift, coordinate workflow adjustments, and handle personnel issues to optimize overall plant performance. Both roles require real-time problem solving, but Shift Supervisors focus more on strategic resource allocation and cross-functional communication.

Leadership and Team Management

Line Leaders focus on direct oversight of production workers, ensuring tasks are completed efficiently while maintaining quality standards on the manufacturing floor. Shift Supervisors hold broader responsibilities, managing multiple line leaders and coordinating overall shift operations to optimize productivity and address workflow challenges. Both roles require strong leadership skills, but shift supervisors emphasize strategic planning and cross-team communication in addition to hands-on team management.

Decision-Making Authority

Line Leaders in manufacturing typically have decision-making authority limited to immediate operational tasks such as quality control, workflow adjustments, and team coordination on the production line. Shift Supervisors hold broader decision-making power, encompassing resource allocation, personnel management, and critical problem-solving across multiple production lines during their shift. The distinction in authority impacts efficiency, with Shift Supervisors responsible for strategic decisions that ensure overall shift productivity and Line Leaders focusing on tactical execution within their specific line.

Training and Development Duties

Line Leaders are primarily responsible for on-the-floor training, ensuring team members adhere to production standards and safety protocols through hands-on guidance. Shift Supervisors oversee broader training initiatives, coordinating skill development programs and evaluating employee performance to enhance overall shift productivity. Both roles play crucial parts in continuous workforce development but vary in scope, with Line Leaders focusing on immediate task proficiency and Shift Supervisors managing strategic training objectives.

Performance Metrics and Evaluation

Line Leaders are evaluated based on production output, quality control adherence, and real-time problem-solving efficiency, directly impacting daily manufacturing line performance. Shift Supervisors are assessed through broader metrics including overall shift productivity, workforce management, safety compliance, and cross-departmental coordination. Performance evaluations for both roles emphasize meeting Key Performance Indicators (KPIs) such as throughput rates, defect reduction, downtime minimization, and team engagement levels to drive operational excellence.

Career Growth Opportunities

Line Leaders typically manage frontline production teams, developing essential leadership skills that pave the way for advancement into supervisory roles. Shift Supervisors oversee multiple line leaders and broader operational activities, gaining strategic experience crucial for higher management positions. Transitioning from Line Leader to Shift Supervisor represents a significant career growth opportunity, enhancing organizational influence and decision-making responsibilities in manufacturing environments.

Comparing Impact on Manufacturing Efficiency

Line Leaders directly influence manufacturing efficiency by managing day-to-day operations on the production floor, ensuring tasks are completed promptly and quality standards are met. Shift Supervisors oversee multiple line leaders and coordinate shift schedules, enabling smoother workflow transitions and minimizing downtime. The combined impact of Line Leaders' hands-on management and Shift Supervisors' strategic oversight drives optimal productivity and reduces operational bottlenecks in manufacturing facilities.

Line Leader vs Shift Supervisor Infographic

jobdiv.com

jobdiv.com