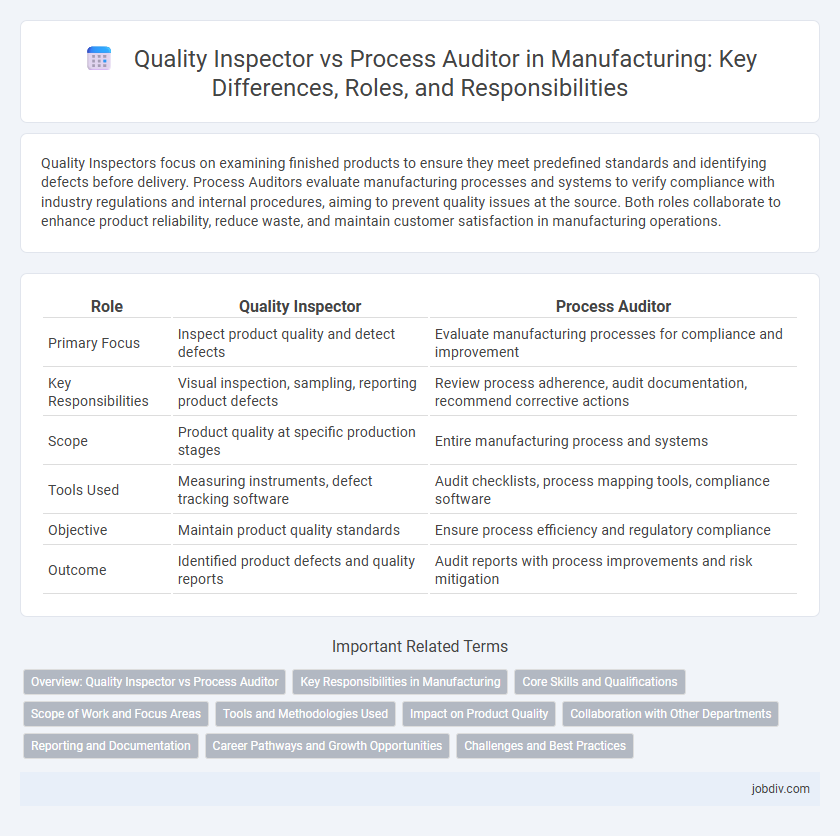

Quality Inspectors focus on examining finished products to ensure they meet predefined standards and identifying defects before delivery. Process Auditors evaluate manufacturing processes and systems to verify compliance with industry regulations and internal procedures, aiming to prevent quality issues at the source. Both roles collaborate to enhance product reliability, reduce waste, and maintain customer satisfaction in manufacturing operations.

Table of Comparison

| Role | Quality Inspector | Process Auditor |

|---|---|---|

| Primary Focus | Inspect product quality and detect defects | Evaluate manufacturing processes for compliance and improvement |

| Key Responsibilities | Visual inspection, sampling, reporting product defects | Review process adherence, audit documentation, recommend corrective actions |

| Scope | Product quality at specific production stages | Entire manufacturing process and systems |

| Tools Used | Measuring instruments, defect tracking software | Audit checklists, process mapping tools, compliance software |

| Objective | Maintain product quality standards | Ensure process efficiency and regulatory compliance |

| Outcome | Identified product defects and quality reports | Audit reports with process improvements and risk mitigation |

Overview: Quality Inspector vs Process Auditor

Quality Inspectors focus on identifying defects and ensuring products meet specific quality standards by performing detailed inspections at various stages of production. Process Auditors evaluate manufacturing processes for compliance with regulatory requirements and internal standards, emphasizing process efficiency and continual improvement. Both roles are essential for maintaining overall product quality but differ in scope, with Inspectors centered on product conformity and Auditors on process integrity.

Key Responsibilities in Manufacturing

Quality Inspectors in manufacturing are responsible for examining products and materials to ensure they meet specified standards, performing detailed visual and dimensional checks, and documenting defects for corrective action. Process Auditors focus on evaluating manufacturing processes by reviewing compliance with established procedures, identifying process inefficiencies, and recommending improvements to maintain quality consistency. Both roles are critical in maintaining product quality, with Quality Inspectors emphasizing product verification and Process Auditors emphasizing process validation.

Core Skills and Qualifications

Quality Inspectors require strong attention to detail, proficiency in inspection tools, and knowledge of quality standards such as ISO 9001. Process Auditors must possess expertise in process auditing techniques, risk assessment, and compliance verification to evaluate manufacturing workflows effectively. Both roles benefit from analytical skills and understanding of regulatory requirements, but Quality Inspectors emphasize product testing while Process Auditors focus on process improvement.

Scope of Work and Focus Areas

Quality Inspectors primarily concentrate on identifying defects and ensuring products meet predefined standards through direct examination at various production stages. Process Auditors focus on evaluating the effectiveness and compliance of manufacturing processes against quality management systems, emphasizing systematic process improvements. Their scope diverges as Inspectors handle product-level quality validation while Auditors oversee process adherence and operational efficiency.

Tools and Methodologies Used

Quality inspectors primarily utilize tools such as calipers, micrometers, and coordinate measuring machines (CMM) to directly assess product dimensions and defects, ensuring compliance with specifications. Process auditors employ methodologies like statistical process control (SPC), Six Sigma techniques, and root cause analysis to evaluate and improve manufacturing processes for overall quality consistency. Both roles depend on data collection software and standardized checklists to support accurate reporting and continuous improvement initiatives.

Impact on Product Quality

Quality Inspectors play a critical role in product quality by identifying defects and ensuring compliance with specifications during production stages, which directly reduces the risk of faulty products reaching customers. Process Auditors focus on evaluating and improving manufacturing processes, thereby enhancing overall process efficiency and preventing quality issues at their root cause. Combining both roles leads to a robust quality management system that supports sustained product excellence and customer satisfaction.

Collaboration with Other Departments

Quality Inspectors collaborate closely with production teams to identify defects and ensure adherence to product specifications, fostering immediate corrective actions. Process Auditors work alongside process engineering and quality assurance departments to evaluate and improve manufacturing workflows, promoting compliance with industry standards. Both roles enhance cross-departmental communication by providing critical data that supports continuous improvement and operational efficiency.

Reporting and Documentation

Quality Inspectors generate detailed reports documenting product conformity, deviations, and non-compliance issues, using checklists and standardized forms to ensure traceability. Process Auditors create comprehensive audit reports that evaluate process effectiveness, regulatory adherence, and system improvements, often including root cause analysis and corrective action recommendations. Both roles utilize digital documentation systems to enhance accuracy, maintain records, and support continuous quality improvement initiatives in manufacturing.

Career Pathways and Growth Opportunities

Quality Inspectors typically begin their careers by performing hands-on inspection and testing of products to ensure compliance with standards, gaining foundational knowledge in quality control. Process Auditors progress by evaluating and improving manufacturing processes, requiring a deeper understanding of operational workflows and regulatory requirements, which opens up opportunities for leadership roles in quality management. Both career paths offer growth through certifications such as Six Sigma or ASQ, but Process Auditors often advance faster into strategic positions overseeing entire quality systems.

Challenges and Best Practices

Quality inspectors often face challenges in identifying subtle defects and ensuring product compliance under tight production schedules, requiring keen attention to detail and adherence to inspection protocols. Process auditors encounter difficulties in evaluating complex manufacturing processes and detecting deviations from standards, necessitating thorough process knowledge and systematic audit techniques. Best practices include leveraging data analytics for real-time defect tracking, continuous training to enhance inspector and auditor skills, and fostering cross-functional collaboration to improve overall quality management.

Quality Inspector vs Process Auditor Infographic

jobdiv.com

jobdiv.com