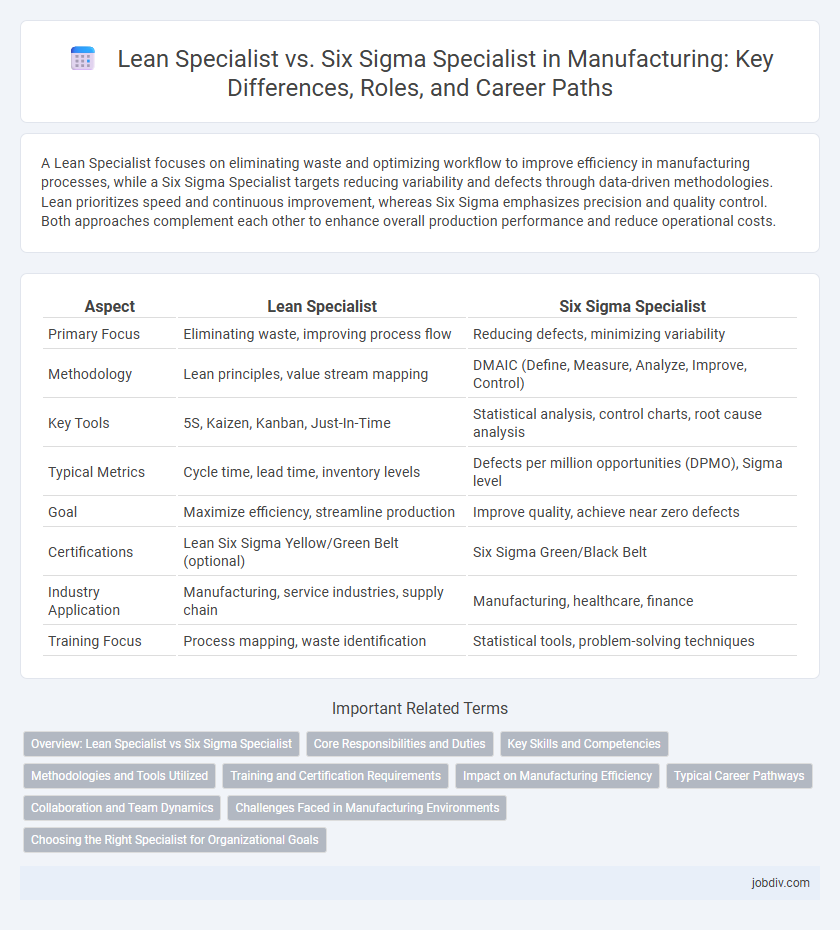

A Lean Specialist focuses on eliminating waste and optimizing workflow to improve efficiency in manufacturing processes, while a Six Sigma Specialist targets reducing variability and defects through data-driven methodologies. Lean prioritizes speed and continuous improvement, whereas Six Sigma emphasizes precision and quality control. Both approaches complement each other to enhance overall production performance and reduce operational costs.

Table of Comparison

| Aspect | Lean Specialist | Six Sigma Specialist |

|---|---|---|

| Primary Focus | Eliminating waste, improving process flow | Reducing defects, minimizing variability |

| Methodology | Lean principles, value stream mapping | DMAIC (Define, Measure, Analyze, Improve, Control) |

| Key Tools | 5S, Kaizen, Kanban, Just-In-Time | Statistical analysis, control charts, root cause analysis |

| Typical Metrics | Cycle time, lead time, inventory levels | Defects per million opportunities (DPMO), Sigma level |

| Goal | Maximize efficiency, streamline production | Improve quality, achieve near zero defects |

| Certifications | Lean Six Sigma Yellow/Green Belt (optional) | Six Sigma Green/Black Belt |

| Industry Application | Manufacturing, service industries, supply chain | Manufacturing, healthcare, finance |

| Training Focus | Process mapping, waste identification | Statistical tools, problem-solving techniques |

Overview: Lean Specialist vs Six Sigma Specialist

Lean Specialists prioritize waste reduction and process efficiency by implementing Lean principles such as 5S, Kaizen, and value stream mapping to streamline manufacturing workflows. Six Sigma Specialists focus on reducing process variation and defects through data-driven methodologies like DMAIC and statistical analysis to enhance product quality. Both roles complement each other in manufacturing environments by improving operational performance and customer satisfaction.

Core Responsibilities and Duties

Lean Specialists focus on streamlining manufacturing processes by identifying waste and implementing continuous improvement strategies to enhance efficiency. Six Sigma Specialists utilize data-driven methodologies and statistical analysis to reduce defects and improve product quality. Both roles collaborate to optimize production workflows but emphasize different approaches: Lean centers on process flow and waste reduction, while Six Sigma targets variability and quality control.

Key Skills and Competencies

Lean Specialists excel in process improvement through waste reduction and value stream mapping, emphasizing continuous flow and just-in-time production. Six Sigma Specialists possess advanced statistical analysis skills and expertise in DMAIC methodology to reduce variability and defects, driving quality control and process efficiency. Both require strong problem-solving abilities, but Lean focuses on operational speed while Six Sigma targets precision and consistency.

Methodologies and Tools Utilized

Lean specialists utilize methodologies focusing on waste reduction, value stream mapping, and continuous flow to enhance efficiency and eliminate non-value-added activities. Six Sigma specialists employ data-driven techniques such as DMAIC (Define, Measure, Analyze, Improve, Control) and statistical tools like control charts and hypothesis testing to reduce variation and improve process quality. Both specialists leverage root cause analysis and process mapping but differ in Lean's emphasis on speed and flow versus Six Sigma's focus on defect reduction and precision.

Training and Certification Requirements

Lean Specialists typically require training in Lean principles such as waste reduction and value stream mapping, often supported by certification levels like Lean Bronze, Silver, or Black Belt. Six Sigma Specialists must undergo rigorous training in statistical analysis and process improvement methodologies, culminating in certifications such as Green Belt, Black Belt, or Master Black Belt from recognized institutions like ASQ or IASSC. Both roles demand continuous professional development to maintain certifications and stay updated on industry best practices.

Impact on Manufacturing Efficiency

Lean Specialists optimize manufacturing efficiency by eliminating waste and streamlining production processes through value stream mapping and continuous improvement techniques. Six Sigma Specialists enhance quality and reduce defects by applying statistical analysis and DMAIC methodology to minimize variability in manufacturing operations. Both roles significantly improve manufacturing efficiency but Lean focuses on flow and waste reduction, while Six Sigma targets precision and defect control.

Typical Career Pathways

Lean Specialists often begin their careers as process improvement coordinators or manufacturing engineers, advancing to roles such as Lean Coordinators, Lean Managers, and ultimately Continuous Improvement Directors. Six Sigma Specialists typically start as quality analysts or process engineers, progressing through Belt certifications (Green Belt, Black Belt) to positions like Six Sigma Black Belt, Master Black Belt, and Quality Manager. Both career paths emphasize skill development in data analysis, project management, and operational efficiency to drive manufacturing excellence.

Collaboration and Team Dynamics

Lean Specialists excel in streamlining workflows and eliminating waste through collaborative team efforts, fostering a culture of continuous improvement. Six Sigma Specialists utilize data-driven methods and cross-functional teamwork to reduce process variability and enhance quality control. Effective collaboration between Lean and Six Sigma Specialists integrates efficiency with precision, driving superior manufacturing outcomes and dynamic team synergy.

Challenges Faced in Manufacturing Environments

Lean Specialists often face challenges in manufacturing environments related to sustaining waste reduction initiatives while maintaining production flow and employee engagement. Six Sigma Specialists encounter difficulties in collecting accurate data and managing complex statistical analysis to identify root causes of defects under tight production deadlines. Both roles must navigate resistance to change, limited resources, and the integration of continuous improvement methodologies within existing operational workflows.

Choosing the Right Specialist for Organizational Goals

Choosing the right specialist depends on organizational goals: Lean Specialists excel in eliminating waste and improving process flow, ideal for enhancing operational efficiency and reducing cycle time. Six Sigma Specialists focus on reducing process variation and improving quality through data-driven decision making, suitable for organizations targeting defect reduction and maximizing customer satisfaction. Aligning the specialist's strengths with specific manufacturing objectives ensures optimal resource utilization and sustainable performance improvements.

Lean Specialist vs Six Sigma Specialist Infographic

jobdiv.com

jobdiv.com